Scroll to:

Study on Processing Grinding Sludge Conglomerates in Devices with a Rotating Electromagnetic Field

https://doi.org/10.23947/2687-1653-2022-22-4-338-345

Abstract

Introduction. The key stages of sludge processing technology are the destruction of conglomerates into metal and non-metal components, as well as the grinding of component particles to obtain secondary raw materials of the required granulometric composition. The use of a rotating electromagnetic field for processing grinding sludge makes it possible

to exclude the application of various means of destruction and grinding, avoiding contact interaction of agglomerates and the walls of the working chamber. Thus, the material consumption of technical means is reduced, and the efficiency of the destruction process is increased.

The study aimed at establishing the features and basic patterns of sludge waste processing in devices with a rotating electromagnetic field.

Materials and Methods. For the research, grinding sludge was used, which was a collection of conglomerates of arbitrary shape, consisting of 80-85 % of metal chips. An induction method was applied based on establishing the connection of the EMF induced in an induction sensor and the magnetic induction of a rotating electromagnetic field. The influence of induction on the nature of interaction between sludge particles in a rotating electromagnetic field was evaluated by changing the relative EMF signal induced in an inductive sensor.

Results. As a result of experimental studies conducted using the induction method, it has been found that the dynamic characteristics of sludge waste conglomerates depend on the induction of a rotating field to a certain value. With an increase in the size of sludge conglomerates, with the same size of ferromagnetic particles entering it, the magnitude of the magnetic field induction required for their destruction decreased. With a decrease in the particle size of conglomerates, the field induction required for the destruction of conglomerate bonds increased. An increase in the number of particles in the conglomerate reduced the value of induction. The degree of destruction of the conglomerate and the grinding of its ferromagnetic particles depended on the duration of the rotating electromagnetic field induction.

Discussion and Conclusions. The proposed induction method makes it possible to investigate the influence of electromagnetic field parameters on the change in the state of the magnetic vibrating layer, as well as to evaluate the kinematic characteristics of ferromagnetic medium particles in the magnetic vibrating layer.

Keywords

For citations:

Lebedev V.A., Schirin A.A., Koval N.S., Vernigorov Yu.M. Study on Processing Grinding Sludge Conglomerates in Devices with a Rotating Electromagnetic Field. Advanced Engineering Research (Rostov-on-Don). 2022;22(4):338-345. https://doi.org/10.23947/2687-1653-2022-22-4-338-345

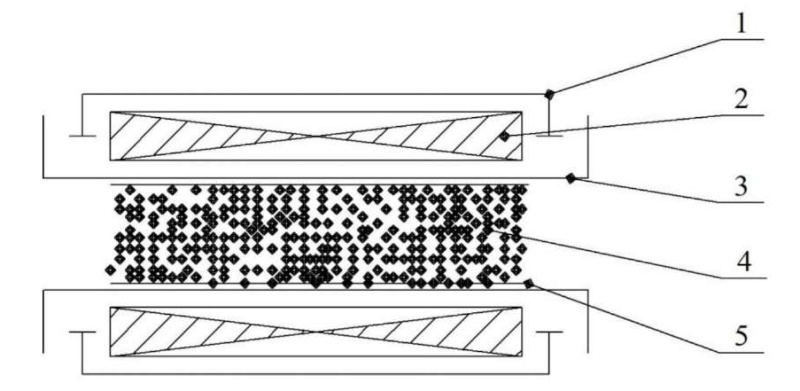

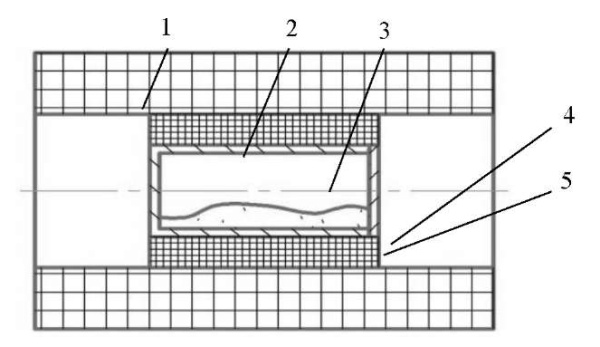

Introduction. The technology of processing one of the most complex types of metal production waste — grinding sludge — to reuse its components in powder metallurgy and foundry production requires a number of successive stages: separation of process liquid (PL), drying, destruction of conglomerates, grinding, and separation of sludge solids [1–10]. The analysis has shown that the last two stages of sludge processing are the most labor-intensive, and the technical means and devices used for their implementation, despite their diversity, are ineffective in a number of technical-and-economic indices [1–15]. The latest achievements in the field of magnetism provide solving this problem on a qualitatively new level using a rotating electromagnetic field (Fig. 1).

Fig. 1. Sludge processing scheme in a rotating electromagnetic field:

1 — housing; 2 — inductor; 3 — working area; 4 — sludge; 5 — replaceable sleeve (the authors' figure)

The use of a rotating electromagnetic field (REMF) for the processing of grinding sludge makes it possible to exclude the contact interaction of conglomerates with the working chamber walls and the use of metal beaters or other means of destruction and grinding. Thus, the material consumption of technical means is reduced, the efficiency of the processes of destruction of conglomerates and the grinding of metal particles of sludge is increased [16][17].

A set of theoretical and experimental studies has been carried out to define the features and basic laws of sludge waste processing in devices with a rotating electromagnetic field. The results are presented in this paper.

Materials and Methods. The sludge to be destroyed and crushed is a collection of conglomerates of arbitrary shape, consisting of 80–85 % metal chips, which makes it possible to characterize the conglomerate as a solid with ferromagnetic properties [14].

When conglomerates are found in a rotating electromagnetic field characterized by induction 𝐵=𝐵v𝑐𝑜𝑠𝜔𝑡 and angular velocity ω, they perform a complex movement, bringing the system into a magneto-vibratory state. In this case, a magnetic vibrating layer (MVL) is formed, under which their contact interaction and, as a consequence, destruction and grinding occur.

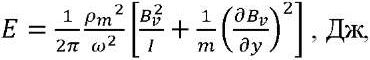

The energy state of conglomerates in the MVL is described by the dependence in the form:

(1)

(1)

where 𝑝𝑚 — magnetic moment, Am2;  — field gradient, A/m2.

— field gradient, A/m2.

Based on equation (1), the energy conditions for the destruction of conglomerates are established:

(2)

(2)

where 𝐸адг — adhesive strength of conglomerates, J.

Conditions for grinding ferromagnetic sludge particles with a degree of 𝑍𝑢 = 𝐷Н ⁄ 𝐷К based on (1), has the form:

(3)

(3)

where σ — ultimate strength at destruction of ferromagnetic particles, Pa; Dн and Dк — initial and final equivalent diameters of the particles, m; Е — elastic modulus of the particle, Pa.

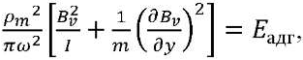

To study the influence of the electromagnetic field on the energy state of the MVL, an induction method was used (Fig. 2), based on establishing the connection of the EMF induced in the induction sensor with the magnetic induction of a rotating electromagnetic field.

Fig. 2. Scheme for implementation of studies on the MVL state in a rotating electromagnetic field by induction method:

1 — inductor, 2 — inductive coil, 3 — cuvette, 4 — sludge, 5 — cuvette cover (the authors' figure)

An inductance coil is selected as the sensor. To create the coil, a frame with a width (H) of 25 mm and an outer radius (R2) of 17.5 mm was made. Winding wire — PEL (GOST 2 773-78) with diameters: copper D1 = 0.15 mm, insulated D = 0.18 mm. The cross-sectional area of the wire was S = 0.01767 mm2. The measured resistance of the coil was 14.8 ohms. The inductance was 0.82 mH. The total number of turns was 139, the wire length was 15.27 m. The calculated resistance of the coil (1 m — 0.99 ohms) R = 15.27× 0.99 = 15.1 ohms.

The inductive sensor 2 and the cuvette 3 were placed in a cylindrical working area of the device with a rotating electromagnetic field (Fig. 1). The current in the circuit of the inductive sensor was controlled by a multimeter. Under various modes, it was 4.3–11.4 A. First, the induction EMF was measured without sludge waste particles, and then — with the studied samples of sludge waste at the selected parameters of the device with REMF.

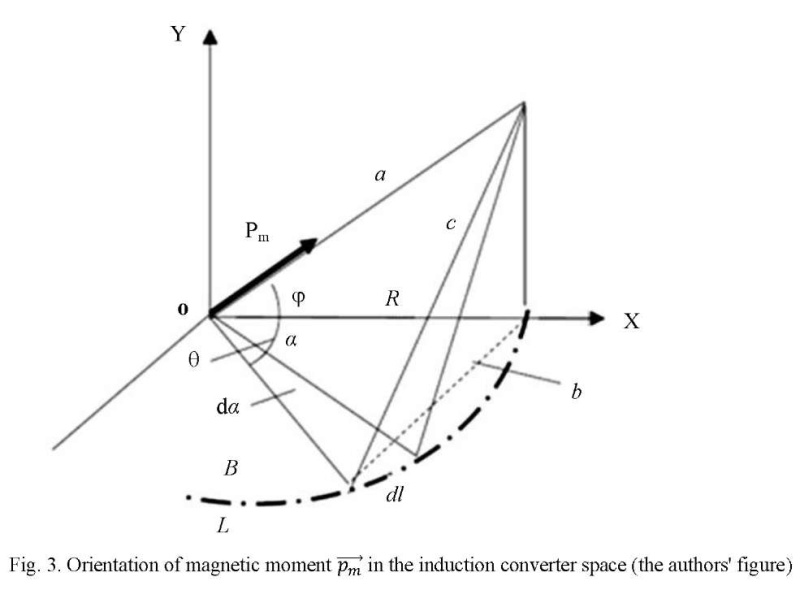

Sludge waste conglomerates in a rotating electromagnetic field under the action of a moment tending to rotate them around the center of mass, perform, on the one hand, rotational motion, and on the other, translational motion in the direction of the external rotating electromagnetic field. Thus, the behavior of the magnetic moments of conglomerates under the action of ponderomotive forces can be characterized in the plane of the measuring coil of the XOY induction sensor as vibration-rotational and vibration-translational motion according to the harmonic law in a magnetic field (Fig. 3).

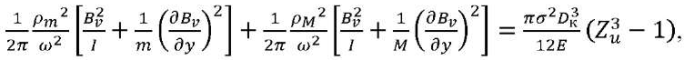

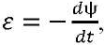

The induced EMF, in accordance with the law of electromagnetic induction, is equal to:

(4)

(4)

where ψ = NΦ — flux linkage; N — turn number of the measuring coil.

We express magnetic flux through the surface bounded by the contour of the coil of the induction converter L with radius R, in the following form:

Φ=𝐵𝑆к, (5)

where 𝑆к — coil contour area; 𝑆к = 𝜋𝑟2; 𝑟 — middle radius of the coil contour, 𝐵 — induction of a rotating electromagnetic field. In this case:

𝐵=𝐵0. (6)

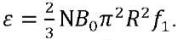

The expression for calculating EMF of a multiturn induction converter is as follows

(7)

(7)

The influence of induction on the nature of the interaction between sludge particles in a rotating electromagnetic field was evaluated through changing the relative EMF signal induced in an inductive sensor, according to the ratio:

(8)

(8)

where ε and ε0 — EMF in the sensor with and without medium, respectively.

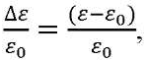

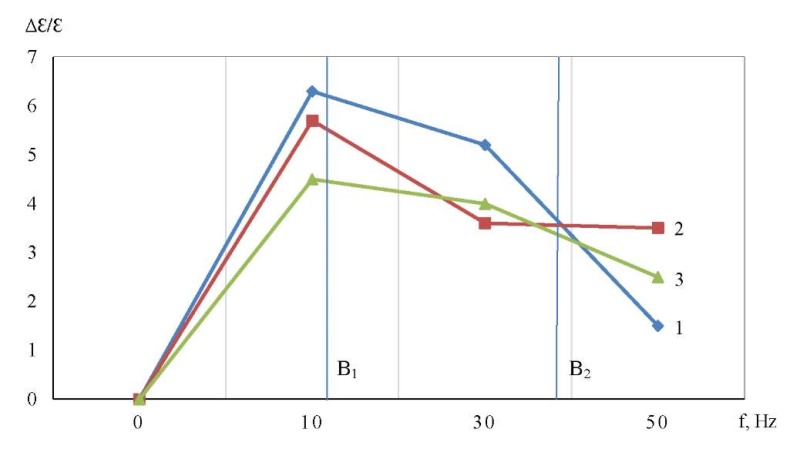

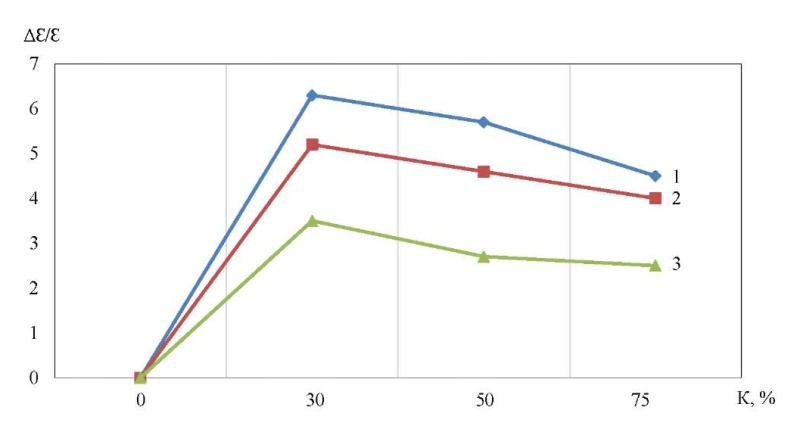

Research Results. Figures 4, 5 show the results of an induction study of the effect of a rotating electromagnetic field on the energy state of sludge particles, and Figures 6–8 show the main technological patterns of the process of destruction of conglomerates in devices with a rotating electromagnetic field.

Fig. 4. Experimental dependence of relative signal Δ𝜀⁄𝜀 on supply frequency (f),

which determines induction of a rotational electromagnetic field at the level

of loading of the working area of the device with a ferromagnetic medium:

1 — 0.3 %; 2 — 0.5 %; 3 — 0.75 % (the authors' figure)

Fig. 5. Experimental dependence of relative signal Δ𝜀⁄𝜀 on the sludge loading factor in the working area

of the device with a REMF determining induction of a rotational electromagnetic field:

1 — 10 Hz; 2 — 30 Hz; 3 — 50 Hz (the authors' figure)

Fig. 6. Effect of the size of sludge conglomerates on the magnetic field induction value

required for their destruction at the particle size r in the conglomerate:

1 — 50 μm; 2 — 40 μm; 3 — 30 μm; 4 — 20 μm; 5 — 10 μm (the authors' figure)

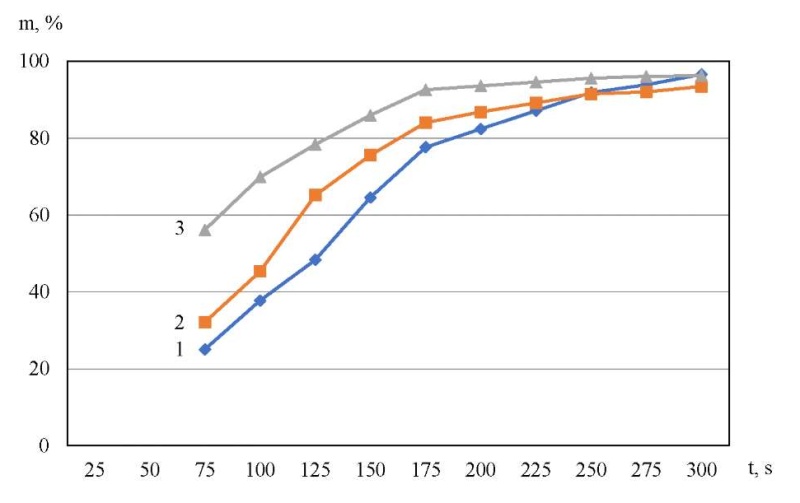

Fig. 7. Dependence of the separated abrasive on time at output current frequencies:

1 — 50 Hz; 2 — 30 Hz; 1 — 10 Hz (the authors' figure)

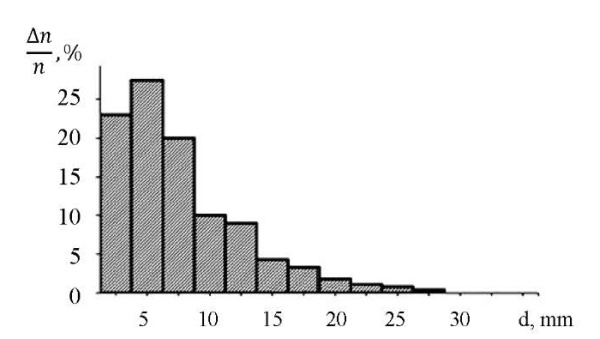

Fig. 8. Histogram of particle size distribution after 5 minutes of exposure to the magnetic vibrating layer (the authors' figure)

Discussion and Conclusions. Experimental studies conducted by the induction method have clearly shown that the dynamic characteristics of sludge waste conglomerates depend on the induction of a rotating field. As shown in Figure 4, a change in the field induction to value В1 contributes to an increase in the energy activity of conglomerates in the magnetic vibrating layer. The processes that provide the technological effect of destruction of sludge waste conglomerates with a size of 10 μm proceed more intensively. A further increase in induction from B1 to B2 causes a decrease in the energy activity of conglomerates in the MVL, as shown by the induction method. This is due to the fact that with increasing induction, the degree of chaotization of conglomerates decreases, and chain complexes begin to form from them, creating so-called “magnetic strings”, whose vibration speed and amplitude are less than the vibration speed and amplitude of individual conglomerates. At B > B2, “magnetic strings”, due to the growth of magnetostatic interaction, assume a stable character, significantly reducing the effect of magnetic vibration of sludge waste conglomerates, practically reducing it to zero at a high level of induction of a rotating electromagnetic field.

The study results presented in Figures 6–8 allowed us to draw the following conclusions:

- with an increase in the size of the sludge conglomerates, with the same size of the ferromagnetic particles entering it, the magnetic field induction value required for their destruction decreases, which is consistent with the model representations of the energy evaluation of the magnetic vibrating layer;

- with a decrease in the particle sizes of conglomerates, the field induction required for the destruction of conglomerate bonds increases; curve analysis suggests that for conglomerates consisting of particles with a radius of less than 3 μm, the induction exceeds 2–4 mT;

- the proposed model for estimating the energy state is valid for the destruction of less stable conglomerates;

- an increase in the number of particles in the conglomerate reduces the value of the induction that destroys it;

- the degree of destruction of conglomerates and grinding of its ferromagnetic particles depends on the duration of the induction of a rotating electromagnetic field.

References

1. Бабичев, А. П. Режимы работы устройства тонкого помола порошка SmCo<sub>5</sub> / А. П. Бабичев, Ю. М. Вернигоров, Н. Н. Фролова // Фундаментальные и прикладные проблемы техники и технологии. — 2012. — № 6 (296). — С. 64–70.

2. Переработка производственных отходов и вторичных сырьевых ресурсов, содержащих редкие, благородные и цветные металлы / В. И. Букин [и др.] — Москва : Деловая столица, 2002. — 224 с.

3. Комаров, О. С. Переработка и использование отходов, содержащих цветные металлы / О. С. Комаров, Д. О. Комаров, Н. И. Урбанович. — Минск : БНТУ, 2018. — 114 с.

4. Рева, В. П. Механохимическая технология переработки отходов металлообработки быстрорежущей стали / В. П. Рева, Д. В. Моисеенко // Вестник машиностроения. — 2013. — № 2. — С. 51–56.

5. Переработка промышленных отходов металлопроизводства / В. А. Шаповалов [и др.] // Современная электрометаллургия. — 2013. — № 1. — С. 40–44.

6. Каяк, Г. Л. Разработка технологии утилизации шлифовального шлама / Г. Л. Каяк, В. С. Фоменко, В. В. Андреев // Вестник инженерной школы Дальневосточного федерального университета. — 2017. — № 1. (30). — С. 60–67. doi: 10.5281/zenodo.399007

7. Дьяконов, О. М. Шламы металлообрабатывающего производства / О. М. Дьяконов // Литье и металлургия. — 2010. — № 1–2. — С. 154–159.

8. Повстяной, А. Ю. Использование отходов промышленного производства для изготовления материалов конструкционного назначения / А. Ю. Повстяной, В. Д. Рудь // Устойчивое развитие. — 2014. — № 19. — С. 159–164.

9. Lebedev, V. A. Method of Calculating the Machines Drive with Screw Working Bodies Mounted from Tetrahedral Hollows / V. A. Lebedev, G. V. Serga, M. M. Chaava //In: Proceedings of the 6th International Conference on Industrial Engineering. — 2021. — Р. 557–563. doi: 10.1007/978-3-030-54814-8_64

10. The Study of Fine-Cleaning Treatment for Removal of Burrs in Screw Rotors / V. A. Lebedev, G. V. Serga, M. M. Chaava [et al.] // IOP Conference Series: Materials Science and Engineering. — 2021. — Vol. 1029. — Art. 012001. doi: 10.1088/1757-899X/1029/1/012001

11. Reliability of Centrifugal–Rotational Finishing by Steel Shot / M. A. Tamarkin, E. E. Tishchenko, D. V. Kazakov, A. G. Isaev // Russian Engineering Research. — 2017. — Vol. 37. — Р. 326–329. doi: 10.3103/S1068798X17040219

12. Creation of Regular Microreliefs by Multicontact Shock Vibratory Tool / D. P. Motrenko, A. P. Babichev, U. A. Babichev, G. A. Prokopez // In: Proceeding of 2nd Asia - Pacific Forum on Precision Surface Finishing and Deburring Technology, July, 22–24, 2002. — Seoul, Korea; 2002. — P. 246–249.

13. Vernigorov, Y. M. Simulation of Destruction of Ferromagnetic Materials Particles in Magneto-Vibrational Layer / Y. M. Vernigorov, K. K. Leletko, N. N. Frolova // World Science: Proceedings of Articles the International Scientific Conference. Czech Republic, Karlovy Vary – Russia, Moscow, June 29–30, 2017. — 2017. — Р. 59–70.

14. Improving the Efficiency of Metal Production Waste Processing in Electromagnetic Field / V. A. Lebedev, Y. M. Vernigorov, A. A. Shirin [et al.] // Materials Science Forum. — 2021. — Vol. 1037. — Р. 759–766. doi: 10.4028/www.scientific.net/MSF.1037.759

15. Упрочнение длинномерных деталей во вращающемся электромагнитном поле / А. А. Кочубей [и др.] — Ростов-на-Дону : ДГТУ, 2018. — 135 с.

16. Quality Improvement of Powder Products by Means of Magneto-Vibrational Destruction of Aggregates / V. Lebedev, Y. Vernigorov, G. Prokopets, L. Chunakhova // AIP Conference Proceedings. — 2019. — Vol. 2188. — Р. 020007. doi: 10.1063/1.5138381

17. Lebedev, V. A. The Use of the Rotating Electromagnetic Field for Hardening Treatment of Details / V. A. Lebedev, A. A. Kochubey, A. V. Kiricheck // IOP Conference Series: Materials Science and Engineering. — 2017. — Vol. 177. — P. 012126. doi: 10.1088/1757-899X/177/1/012126

About the Authors

V. A. LebedevRussian Federation

Valeriy A. Lebedev

1, Gagarin Sq.

Rostov-on-Don

A. A. Schirin

Russian Federation

Andrey A. Schirin

1, Gagarin Sq.

Rostov-on-Don

N. S. Koval

Russian Federation

Nikolay S. Koval

1, Gagarin Sq.

Rostov-on-Don

Yu. M. Vernigorov

Russian Federation

Yuri M. Vernigorov

1, Gagarin Sq.

Rostov-on-Don

Review

For citations:

Lebedev V.A., Schirin A.A., Koval N.S., Vernigorov Yu.M. Study on Processing Grinding Sludge Conglomerates in Devices with a Rotating Electromagnetic Field. Advanced Engineering Research (Rostov-on-Don). 2022;22(4):338-345. https://doi.org/10.23947/2687-1653-2022-22-4-338-345

JATS XML