Scroll to:

Investigation of the Wear Resistance of a Journal Bearing with Polymer-Coated Grooved Support Ring

https://doi.org/10.23947/2687-1653-2022-22-4-365-372

Abstract

Introduction. In modern heavy-loaded friction units, metallopolymer coated bearings operating in the boundary friction mode are widely used. Their successful application is provided by the viscoelastic deformation of these coatings under load. To pass from boundary friction to liquid friction, it is required to create a bearing hydrodynamic wedge. Currently, the use of journal bearings with polymer-coated grooved support ring is hindered by the lack of a methodology for their calculation. This work analyzes a model of movement of a micropolar lubricant in the operating clearance of a journal

bearing with a nonstandard support profile having a PTFE composite coating with a groove on the bearing surface.

The study aims at establishing the dependence of the stable hydrodynamic regime on the width of the groove on the surface of the bearing profile.

Materials and Methods. Tribological tests of journal bearings with a nonstandard bearing profile having a polymer coating with a groove on the surface were carried out on samples in the form of partial bushes (blocks). Using the equation of movement of a lubricant with micropolar rheological properties, as well as the continuity equation, new mathematical models were obtained that took into account the width of the groove, polymer coating, and nonstandard bearing profile.

Results. A significant expansion of the applicability of design models of journal bearings with structural changes has been achieved. Polymer-coated bearings with a groove provided a hydrodynamic lubrication mode. The results obtained allowed us to evaluate the operational characteristics of the bearing: hydrodynamic pressure value, load capacity, and coefficient of friction.

Discussion and Conclusions. The design of polymer coated journal bearing and a groove 3 mm wide on the surface of the liner provided a stable ascent of the shaft on the hydrodynamic wedge, which was validated experimentally. The experiments were carried out for journal bearings with a diameter of 40 mm with a groove 1–8 mm wide, at a sliding speed of 0.3–3 m/s and a load of 4.8–24 MPa.

Keywords

For citations:

Vasilenko V.V., Kirishchieva V.I., Mukutadze M.A., Shvedova V.E. Investigation of the Wear Resistance of a Journal Bearing with Polymer-Coated Grooved Support Ring. Advanced Engineering Research (Rostov-on-Don). 2022;22(4):365-372. https://doi.org/10.23947/2687-1653-2022-22-4-365-372

Introduction. The issues of providing the reliability of machines and mechanisms are among the major ones in modern industry. New technologies and calculation methods are being developed and existing ones are being improved to increase the resource of technical devices, their wear resistance, economic and operational characteristics.

It is known that the most common cause of failures of friction units are wear and malfunction, and the proportion of failures reaches 80 %. Investigations conducted in the field of friction units suggest the use of new antifriction coatings, modern varieties of materials, original design features of friction units.

Primarily, during calculations and design, the qualities of friction units are underpinned, while modeling methodologies are constantly being developed and improved [1–5]. The parameters affecting the friction units keep changing in accordance with their working conditions and the materials used to obtain a protective coating on the contact surfaces [6–10]. At the same time, there is a need for new methods for adequate modeling and experimental verification of the models obtained.

It follows from the basic results of [11–15] that the formation of secondary structures of frictional transfer of tribological processes in the system “railway track — rolling stock” during the implementation of metal cladding technologies provides reducing the coefficient of friction and wear, and improving vibration-absorbing properties. It has been found that the transverse deformation of a solid body is reduced by 1.5 % and enables to reduce the wear of wheel sets and rails in indirect sections, as well as to increase the traction power of the locomotive. At that, the longitudinal deformation of the solid increases by 60.6 %.

The research results [16][17] are devoted to the development of a mathematical model of journal bearings of finite length and dampers with porous structural elements on the surface of the bearing bush. The obtained study results enable to increase the bearing capacity by 20–22 % and reduce the transmission coefficient of the damper by 15–17 %, and the coefficient of friction by 13–15 %.

The paper1 shows that the use of a low-melting coating on the surface of the bearing bush as an additional lubricant, taking into account its rheological properties and the melt coating having truly viscous rheological properties, increases the operating time of bearings in the hydrodynamic friction mode by 10–12 % and prevents an emergency shortage of lubricant.

In [19–21], computational models were developed that provided the most effective hydrodynamic lubrication mode both in normal and emergency mode during “lubricant starvation”. They were designed to establish a balanced combination of the composition of metal alloys for coatings of movable and fixed contact surfaces of tribo-nodes and the type of lubricant. As a result, it was found that the degree of improvement for the load capacity was 26.2 %, for the coefficient of friction — 12.8 %.

Based on the above, it can be concluded that it is required to develop new design models of bearings, or improve the accuracy of existing ones. A property of the computational models of journal bearings obtained by the authors is the generalization of a whole complex of additional factors previously considered only individually in a single block.

The study aims at establishing the regularities for a stable hydrodynamic regime due to the width of the groove on the bearing profile surface through applying a polymer coating.

Problem Statement. The laminar flow of a micropolar fluid in the journal bearing clearance between a trunnion and a nonstandard bearing profile on which a polymer coating with a groove is located, is studied. In this case, the speed of rotation of the trunnion is equal to Ω, and the speed of the bushing is zero under the conditions of an adiabatic process.

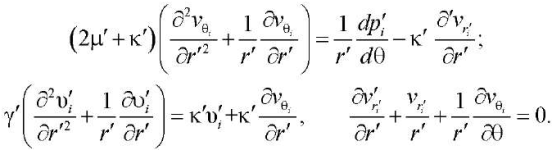

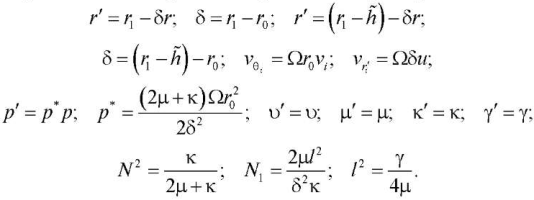

The micropolar lubricant flow is given by the well-known equation in the approximation “for a thin layer” and the continuity equation:

(1)

(1)

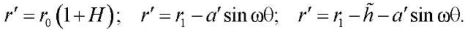

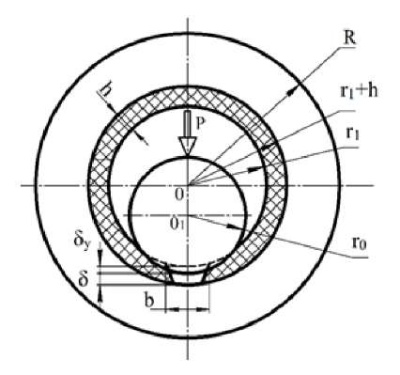

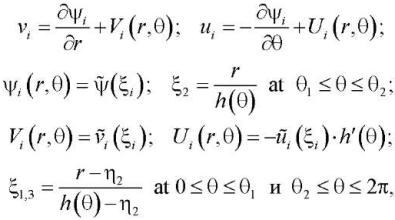

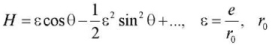

In the polar coordinate system (Fig. 1) with a pole in the center of the bushing, the equation of the trunnion contour, the bushing with a noncircular profile of the bearing surface and the bushing with a nonstandard bearing profile, on which the polymer coating is located, is given as:

(2)

(2)

Fig. 1. Journal bearing having a polymer coating with a groove on the bearing surface (the authors' figure)

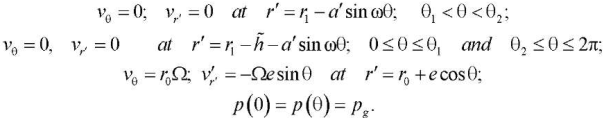

Generally accepted boundary conditions up to terms O(ε2):

(3)

(3)

To make the solution simpler, let us pass on to dimensionless quantities:

(4)

(4)

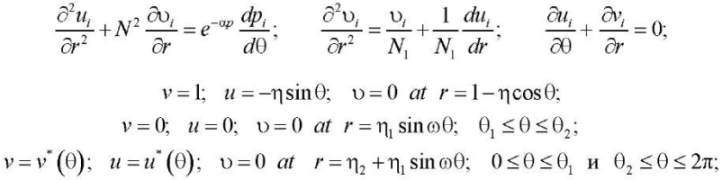

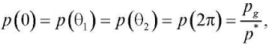

Taking into account (4), equations (1) and (3) are transformed into a system of dimensionless equations with the corresponding boundary conditions, but the condition of constant lubricant consumption should be considered:

(5)

(5)

(6)

(6)

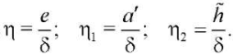

where

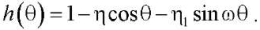

The solution to problem (5), taking into account boundary conditions (6), is sought by the well-known method [20][21] in the form of:

(7)

(7)

where

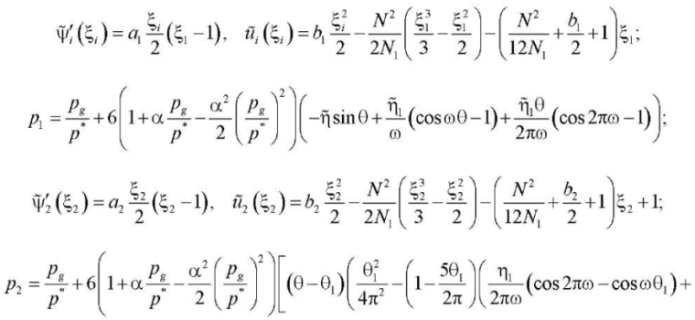

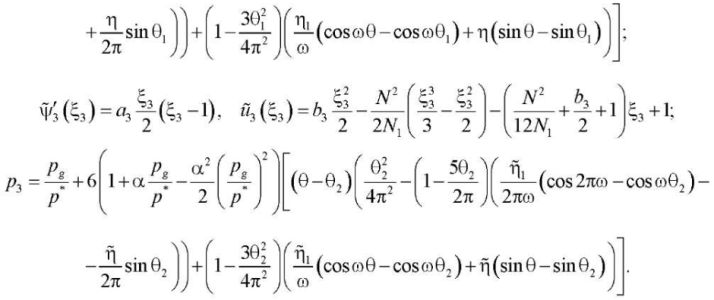

For hydrodynamic pressure and velocity field, we obtain the following analytical expressions:

(8)

(8)

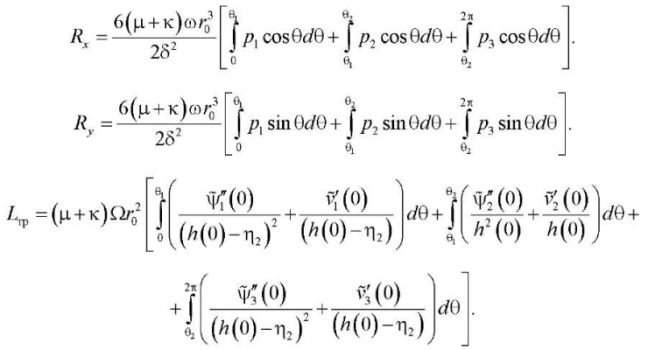

Determining the bearing capacity and friction force, we use the following formulas:

(9)

(9)

Numerical analysis (9) was performed for the following ranges of values: (θ2 – θ1) = 5.74–22.92 (groove width), d = 40 mm; V = 0.3–3 m/s; σ = 4.8–24 MPa; μ0 = 0.0707–0.0076 N∙s/m2 (oil MS-20).

Experimental Procedure. The experimental study consists of:

- verification of the developed calculation model;

- a set of experimental investigations of a bearing with a newly developed design of the bearing surface of the bushing.

The experiment was carried out on an upgraded AI 5018 friction machine using samples in the form of partial bushes. The blocks were cut from the annular blank at a central angle equal to 60 °. Polymer coatings and grooves along the tribocoupling axis to the coating depth were applied to their working surfaces. In addition, the blocks had holes for thermocouples.

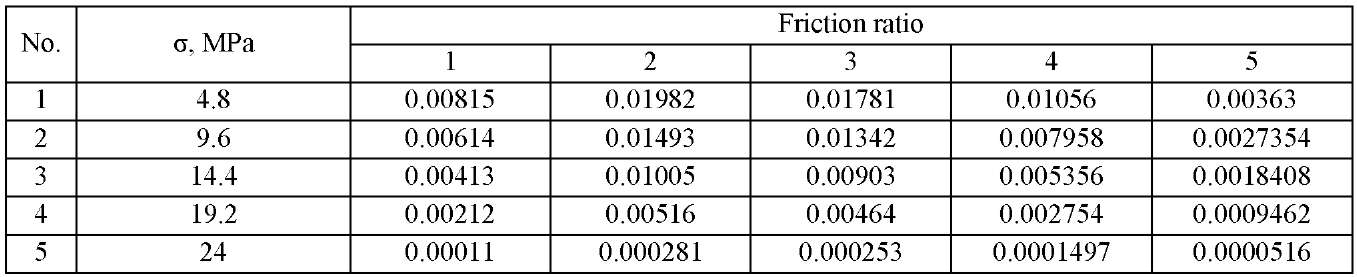

Research Results. As a result of theoretical research, it has been found that the bearing capacity of a journal bearing with a polymer coating of the bushing surface containing a groove, as well as a profile of the bearing surface adapted to friction conditions, was increased by 8–9 %, and the coefficient of friction was reduced by 7–8 % (Table 1).

Table 1

Results of theoretical study on the surface of the support ring with fluoroplastic-containing composite polymer coating

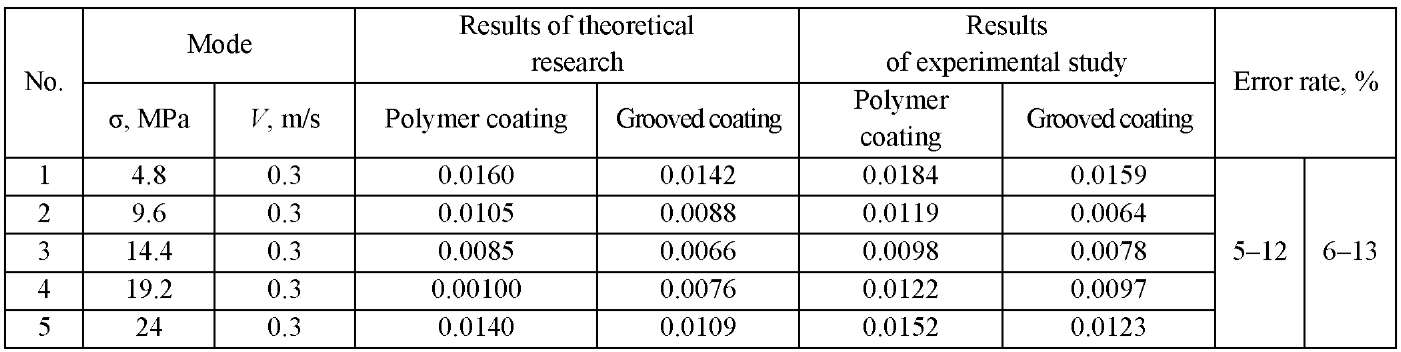

As a result of the experimental study, a stable hydrodynamic regime was obtained after two minutes of processing. The load increased five times with the same interval (Table 2).

Table 2

Results of experimental study on the surface of the support ring with fluoroplastic-containing composite polymer coating

The study results validate the effectiveness of the developed theoretical models and prove the advantage of the investigated journal bearings over existing ones by increasing the load capacity and reducing the friction ratio.

Discussion and Conclusions. Theoretical research determined the required cross section of the oil-supporting grooves to enter the hydrodynamic lubrication mode at a given load. Then, after setting the parameters of the grooves, a computational model was developed describing the operation of the journal bearing in the hydrodynamic mode for a micropolar lubricant, taking into account the bearing profile adapted to the friction conditions.

In the studied design, when the shaft rotates in the groove, a circulating movement of the lubricant occurs. The resulting force lifts the shaft, and a hydrodynamic wedge is formed in the resulting gap.

In accordance with the target goal, the general experimental technique is validated both according to classical single-factor and full-factorial designs.

Conclusions:

- As a result of the study, a significant expansion of the possibilities of applying in practice computational models of a grooved journal bearing with a polymer coating has been achieved. They provide an assessment of operational characteristics, i.e., the magnitude of hydrodynamic pressure, load capacity, and coefficient of friction.

- The use of the studied journal bearings with a groove width of 3 mm significantly increases their load capacity (by 8–9 %) and reduces the friction ratio (by 7–8 %).

- The design of a polymer-coated journal bearing with a 3 mm wide groove provides stable ascent of the shaft on a hydrodynamic wedge.

Reference designation

— components of the velocity vector of the lubricating medium;

— components of the velocity vector of the lubricating medium;  — particle velocity in the micropolar medium;

— particle velocity in the micropolar medium;  — shaft radius; r1 — bushing radius; h̃ — groove height; е — eccentricity; ε — relative eccentricity;

— shaft radius; r1 — bushing radius; h̃ — groove height; е — eccentricity; ε — relative eccentricity;  — bearing design parameter with standard bearing profile;

— bearing design parameter with standard bearing profile;  — bearing design parameter with adapted profile;

— bearing design parameter with adapted profile;  — design parameter characterizing the groove; pg — pressure at the ends of the interval; θ1 and θ2 — the angular coordinates of the groove, respectively; u*(θ) и v*(θ) — known functions due to the presence of a polymer coating on the surface of the bearing sleeve.

— design parameter characterizing the groove; pg — pressure at the ends of the interval; θ1 and θ2 — the angular coordinates of the groove, respectively; u*(θ) и v*(θ) — known functions due to the presence of a polymer coating on the surface of the bearing sleeve.

1. Lagunov EO, Mukutadze MA. The Radial Bearings of Sliding Caused by Fusion. In: Proc. IV Int. Science and Technology Conf. “PROM-ENGINEERING”. Chelyabinsk: South Ural State University; 2018. P. 56–62.

References

1. Polyakov, R. The Method of Long-Life Calculation for a Friction Couple “Rotor – Hybrid Bearing” / R. Polyakov, L. Savin // Proc. 7th Int. Conf. on Coupled Problems in Science and Engineering, Coupled Problems. — Rhodes Island : International Center for Numerical Methods in Engineering. — 2017. — P. 433–440.

2. Поляков, Р. Н. Математическая модель бесконтактного пальчикового уплотнения с активным управлением зазором / Р. Н. Поляков, Л. А. Савин, А. В. Внуков // Фундаментальные и прикладные проблемы техники и технологии. — 2018. — № 1 (327). — С. 66–71.

3. Predictive Analysis of Rotor Machines Fluid-Film Bearings Operability / R. Polyakov, S. Majorov, I. Kudryavcev, N. Krupenin // Vibroengineering PROCEDIA. — 2020. — Vol. 30. — P. 61–67. doi: 10.21595/vp.2020.21379

4. Исследование вязкоупругих и адгезионно-прочностных свойств и разработка эффективных вибропоглощающих композиционных полимерных материалов и покрытий машиностроительного назначения / С. С. Негматов [и др.] // Пластические массы. — 2020. — № 7–8. — С. 32–36. doi: 10.35164/0554-2901-2020-7-8-32-36

5. Application of Artificial Neural Networks to Diagnostics of Fluid-Film Bearing Lubrication / E. P. Kornaeva, A. V. Kornaev, Yu. N. Kazakov, R. N. Polyakov // IOP Conference Series: Materials Science and Engineering. — 2020. — Vol. 734. — Art. 012154. doi: 10.1088/1757-899X/734/1/012154

6. Shutin, D. V. Active Hybrid Bearings as Mean for Improving Stability and Diagnostics of Heavy Rotors of Power Generating Machinery / D. V. Shutin, R. N. Polyakov // IOP Conference Series: Materials Science and Engineering. — 2020. — Vol. 862. — Art. 032098. doi: 10.1088/1757-899X/862/3/032098

7. Analysis of Factors Affecting the Strength of Fixed Bonds Assembled Using Metal-Polymer Compositions / V. E. Zinoviev, P. V. Kharlamov, N. V. Zinoviev, R. A. Kornienko // IOP Conference Series: Materials Science and Engineering. — 2020. — Vol. 900. — Art. 012009. doi: 10.1088/1757-899X/900/1/012009

8. Харламов, П. В. Мониторинг изменений упруго-диссипативных характеристик для решения задач по исследованию трибологических процессов в системе «железнодорожный путь – подвижной состав» / П. В. Харламов // Вестник Ростовского государственного университета путей сообщения. — 2021. — № 1 (81). — С. 122–129. doi: 10.46973/0201-727X_2021_1_122

9. Глушко, С. П. Исследование технологии электроискрового нанесения покрытий, легирования и упрочнения / С. П. Глушко // Advanced Engineering Research. — 2021. — Т. 21, № 3. — С. 253–59. — doi: 10.23947/2687-1653-2021-21-3-253-259

10. Формирование качества поверхностного слоя при абразивной обработке полимеркомпозитных материалов / М. А. Тамаркин [и др.] // Advanced Engineering Research. — 2020. — Т. 20, № 3. — С. 235–242. doi: 10.23947/2687-1653-2020-20-3-235-242

11. Харламов, П. В. Применение физико-химического подхода для изучения механизма образования вторичных структур фрикционного переноса на поверхности контртела / П. В. Харламов // Вестник Ростовского государственного университета путей сообщения. — 2021. — № 3 (83). — С. 37–45. doi: 10.46973/0201-727X_2021_3_37

12. Харламов, П. В. Исследование образования вторичных структур фрикционного переноса на поверхности стальных образцов при реализации технологии металлоплакирования / П. В. Харламов // Сборка в машиностроении, приборостроении. — 2021. — № 12. — С. 556–560. URL: https://www.mashin.ru/eshop/journals/sborka_v_mashinostroenii_priborostroenii/?j_author=%D0%A5%D0%B0%D1%80%D0%BB%D0%B0%D0%BC%D0%BE%D0%B2%20%D0%9F.%D0%92.

13. Металлоплакирование рабочих поверхностей трения пары «колесо – рельс» / В. В. Шаповалов [и др.] // Трение и износ. — 2020. — Т. 41, № 4. — С. 464–474. URL: https://www.elibrary.ru/item.asp?id=43936914

14. Повышение эффективности фрикционной системы «колесо – рельс» / В. В. Шаповалов [и др.] // Вестник научно-исследовательского института железнодорожного транспорта. — 2019. — Т. 78, № 3. — С. 177–182. doi: 10.21780/2223-9731-2019-78-3-177-182

15. Improving the Efficiency of the Path-Rolling Stock System Based on the Implementation of Anisotropic Frictional Bonds / V. V. Shapovalov, V. I. Kolesnikov, P. V. Kharlamov [et al.] // IOP Conference Series : Materials Science and Engineering. — 2020. — Vol. 900. — Art. 012011. doi: 10.1088/1757-899X/900/1/012011

16. Kolesnikov, I. V. Ways of Increasing Wear Resistance and Damping Properties of Radial Bearings with Forced Lubricant Supply: ICIE 2018 / I. V. Kolesnikov, A. M. Mukutadze, V. V. Avilov // In: Proc. 4th Int. Conf. on Industrial Engineering. — 2019. — P. 1049–1062. doi: 10.1007/978-3-319-95630-5_110

17. Демпфер с пористым элементом для подшипниковых опор / К. С. Ахвердиев [и др.] // Трение и износ. — 2016. — Т. 37, № 4. — С. 502–509.

18. Гидродинамический расчет радиального подшипника, смазываемого расплавом легкоплавкого покрытия при наличии смазочного материала / К. С. Ахвердиев [и др.] // Вестник Ростовского государственного университета путей сообщения. — 2017. — № 2 (66). — С. 129–135.

19. Mathematical Model for a Lubricant in a Sliding Bearing with a Fusible Coating in Terms of Viscosity Depending on Pressure under an Incomplete Filling of a Working Gap / D. U. Khasyanova, M. A. Mukutadze, A. M. Mukutadze, N. S. Zadorozhnaya // Journal of Machinery Manufacture and Reliability. — 2021. — Vol. 50. — P. 405–411. doi: 10.3103/S1052618821050083

20. Mukutadze, M. A. Mathematical Model of a Lubricant in a Bearing with a Fusible Coating on the Pilot and Irregular Slider Profile / M. A. Mukutadze, E. O. Lagunova // In: Proc. 7th Int. Conf. on Industrial Engineering (ICIE 2021). — 2022. — P. 834–840. doi: 10.1007/978-3-030-85233-7_97

21. Хасьянова, Д. У. Повышение износостойкости радиального подшипника скольжения, смазываемого микрополярными смазочными материалами и расплавами металлического покрытия / Д. У. Хасьянова, М. А. Мукутадзе // Проблемы машиностроения и надежности машин. — 2022. — № 4. — С. 46–53. URL: https://www.elibrary.ru/item.asp?id=48659076

About the Authors

V. V. VasilenkoRussian Federation

Vladimir V. Vasilenko

2, Rostovskogo Strelkovogo Polka Narodnogo Opolcheniya Sq.

Rostov-on-Don

V. I. Kirishchieva

Russian Federation

Victoria I. Kirishchieva

2, Rostovskogo Strelkovogo Polka Narodnogo Opolcheniya Sq.

Rostov-on-Don

M. A. Mukutadze

Russian Federation

Murman A. Mukutadze

2, Rostovskogo Strelkovogo Polka Narodnogo Opolcheniya Sq.

Rostov-on-Don

V. E. Shvedova

Russian Federation

Valentina E. Shvedova

2, Rostovskogo Strelkovogo Polka Narodnogo Opolcheniya Sq.

Rostov-on-Don

Review

For citations:

Vasilenko V.V., Kirishchieva V.I., Mukutadze M.A., Shvedova V.E. Investigation of the Wear Resistance of a Journal Bearing with Polymer-Coated Grooved Support Ring. Advanced Engineering Research (Rostov-on-Don). 2022;22(4):365-372. https://doi.org/10.23947/2687-1653-2022-22-4-365-372