Scroll to:

Effect of Glass Fiber Reinforcement on the Mechanical Properties of Polyester Composites

https://doi.org/10.23947/2687-1653-2023-23-4-387-397

EDN: LRSXPY

Abstract

Introduction. Glass fibers significantly improve the quality of composite materials, make them lighter, stronger, more corrosion resistant and thermally stable. Strengths and weaknesses of specific composites are actively discussed in the scientific and applied literature. At the same time, the effect of the ratio of fibers and matrix material on the mechanical characteristics of composites has not been sufficiently investigated. The presented study is intended to fill this gap. The work is aimed at manufacturing a composite material on a polymer basis reinforced with glass fiber, and investigating the influence of weight ratios of elements on the mechanical characteristics of the composite. For the first time, a report on the comparison of the characteristics of composites (with different fiber content) to each other and to steel is published.

Materials and Methods. Fiberglass and polyester were used as starting materials with the addition of a mediator to speed up the molding process. The samples were made manually and tested for tensile strength, hardness, and impact strength using standard equipment. The results were summarized in the form of tables, visualized in the form of graphs, and processed by comparative analysis.

Results. The technique of creating samples and methods of their testing were described. The research showed that hardness, tensile strength and impact resistance increased with a growth in the percentage of randomly distributed fiberglass to 50% with 50% unsaturated polyester. In this case, the maximum values of tensile strength — 175.4 MPa, hardness — 38 HV and impact resistance — 1.56 J/mm2 were obtained. The inexpediency of exceeding the proportion of fiberglass by more than 50% was experimentally proven, since mechanical properties deteriorated. This was due, in particular, to the fragility of the glass, which, if the proportions were violated, was transmitted to the entire composite. In addition, with an excessively high volume of reinforcing fibers, the resin was not enough for high-quality bonding of the elements, which significantly reduced the strength of the material. Most of the mechanical characteristics of a composite made of 50% polyester and 50% fiberglass are better than those of steel.

Discussion and Conclusion. It has been proved that the properties of the composite material depend significantly on the glass fiber content. The resulting composite was compared to steel. It turned out that it had better mechanical characteristics and less weight. This allows us to recommend the material for boat hulls.

Keywords

For citations:

Antipas I.R. Effect of Glass Fiber Reinforcement on the Mechanical Properties of Polyester Composites. Advanced Engineering Research (Rostov-on-Don). 2023;23(4):387-397. https://doi.org/10.23947/2687-1653-2023-23-4-387-397. EDN: LRSXPY

Introduction. Polymers are attractive as composite matrices due to their relatively low density, ease of processing, and excellent mechanical properties. High-temperature resins are used for the production of aircraft, rockets, boats, and other equipment. Reinforcement (glass fiber) takes the major load, specifically, if the composite consists of fibers dispersed in a weak matrix (e.g., a carbon-epoxy composite). Thus, the strength and stiffness of the material are determined by the strength and stiffness of the fibers [1–4].

Major advantages of glass fiber-reinforced composites are high strength and modulus of elasticity. Due to their low specific gravity, good strength-to-weight ratio, these materials out-perform metals. In addition, the verified ratio of fatigue strength and weight significantly increases the resistance of many composite laminates to fatigue damage [5][6].

The authors [7] have proved that the mechanical properties of fiber-reinforced composites depend on the properties of the materials included in their composition (type, quantity, distribution and orientation of fibers, voids). The character of interfacial connections and load transfer mechanisms at the phase interface also play an important role.

Studies [8] have shown that the tensile strength of plates from glass fiber varies depending on environmental conditions. In [9], two types of composites with different glass fiber reinforcement were considered: chopped and mixed with unsaturated polyester resin (glass fiber 0/90). It was found that the composite reinforced with chopped glass fiber had a higher modulus of elasticity, maximum stress, and yield strength than the composite reinforced with glass fiber 0/90.

The authors of scientific papers focused on the features of various types of glass fiber and matrix materials. At the same time, the dependence of the quality of the composite on the ratio of the volumes of fibers and the matrix material has not been sufficiently investigated.

In the presented article, the quality of materials is compared in two directions. The first parallel is composites with different ratios of fibers and matrices. The second is composite and steel. The data is published for the first time.

The study aimed at investigating the effect of the glass fiber content on the mechanical properties of the material, i.e., on its behavior under load. Hardness, tear and impact resistance were evaluated.

Materials and Methods. For the production of samples, resin (polyester) with the addition of substances that promote the reaction, and glass fiber were used as starting materials (Fig. 1).

Fig. 1. Glass fiber

The obtained samples were tested for tension, hardness, and shock load. Similar experiments were carried out on steel parts. Each experiment was repeated five times. From test to test, the percentage of glass fiber was increased, and then the average results were taken.

Table 1 shows the mechanical-physical properties of the glass fiber used.

Table 1

Mechanical-physical properties of glass fiber [10]

|

Indicator |

Value |

|

Density, kg/m³ |

2,500 |

|

Tensile strength, MPa |

2,400 |

|

Modulus of elasticity, GPa |

85 |

|

Elongation, % |

0.01 |

Unsaturated polyester, which is a viscous liquid at room temperature, was used as the basic material. Its mechanical properties are shown in Table 2.

Table 2

Mechanical properties of polyester [10]

|

Indicator |

Value |

|

Density, kg/m³ |

1,200 |

|

Tensile strength, MPa |

42 |

|

Modulus of elasticity, GPa |

2.8 |

|

Elongation, % |

3.2 |

Auxiliary materials. The following substances were added to unsaturated polyester [11]:

- cobalt liquid material for hardening (3–4 %);

- mediator — a stimulating substance used to accelerate precipitation (1.5 –3 %).

Measurement of glass fiber density. To determine the density of glass fiber, it was immersed in water in a standard container. The obtained value ρ = 2,500 kg/m³ coincided with the reference value.

Tensile testing of glass fiber. The average diameter of the fibers was determined using a microscope — 20.14 µm. After calculating the cross-section of one fiber, their average number in the bundle was determined through comparing the masses of the fibers and the bundle from which they were taken. The average number of fibers in the bundle turned out to be 2,200. Then, depending on the number of fibers, the bundle cross-section was calculated А = 0.7 mm².

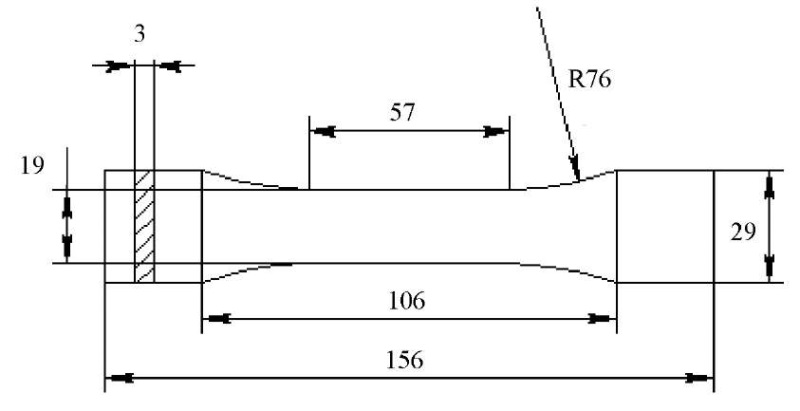

Experiments were hampered by breaks in the attachment points due to the fragility of the fibers. The pressure of the clamps of the stretching device on the ends of the fibers was reduced as follows. Special paper with good absorbency was filled with resinous material, fibers were placed in it and left at room temperature until complete dry-out. Then the paper was cut, and samples were obtained from fiber bundles ready for testing (Fig. 2).

Fig. 2. Tensile samples

The dimensions of the tensile samples were determined in accordance with the international standard requirements ASTM D 2343–951 for such tests. Experimental parameters were as follows: the length of the fibers between mandrels was 25 cm, the length of the mandrels at both ends — 5 cm, the speed of application of the tensile load — 12.7 m/s, laboratory temperature — 23ºС.

Research Results

Sampling. Samples with different mass content of glass fiber were prepared (10%, 20%, 30%, 40%, 50%, and 60%). To do this, a mixture of 5% polyester, cobalt, and a catalyst was prepared at room temperature. A certain amount of it was evenly distributed with a brush over the inner surface of the mold. Then, a layer with randomly distributed glass fibers was applied. Next, the layers of fibers were impregnated with the mixture and superimposed on each other until a final sample of the appropriate proportions was obtained (Fig. 3, 4).

Fig. 3. Sample forms: a — preparation; b — ready-made

Fig. 4. Standard sample form

Finished samples were taken out of the mold, cleaned and placed in a dry environment for 24 hours.

Tensile testing. Tensile tests were carried out in accordance with ISO 326 ASTMD 6382, as shown in Figure 5. The sample was firmly fixed at both ends of the stretching device. A tensile load from zero to 20 N/min was gradually applied to it until the sample was destroyed.

Fig. 5. Stretching device

The stretching process was divided into three areas. In the first one, there was sliding between the clamping jaws and the sample surfaces; therefore, the samples were clamped well. In the second area, due to the elastic behavior of the contacting surfaces of materials, a direct relationship between stress and deformation was observed. The third area was after the destruction of the sample. It was neither complete nor sudden, because it went evenly depending on the orientation angles of the fibers in the layers of glass-fiber mat. As a result, the indicators of maximum tensile strength and elastic deformation of the samples were obtained.

Tensile strength  , which expresses the fracture stress of the composite material, was calculated by ratio [12]:

, which expresses the fracture stress of the composite material, was calculated by ratio [12]:

,

,

where

— maximum force that caused the destruction of the sample, Н;

— maximum force that caused the destruction of the sample, Н;

— sample thickness, mm,

— sample thickness, mm,

— sample thickness, mm.

— sample thickness, mm.

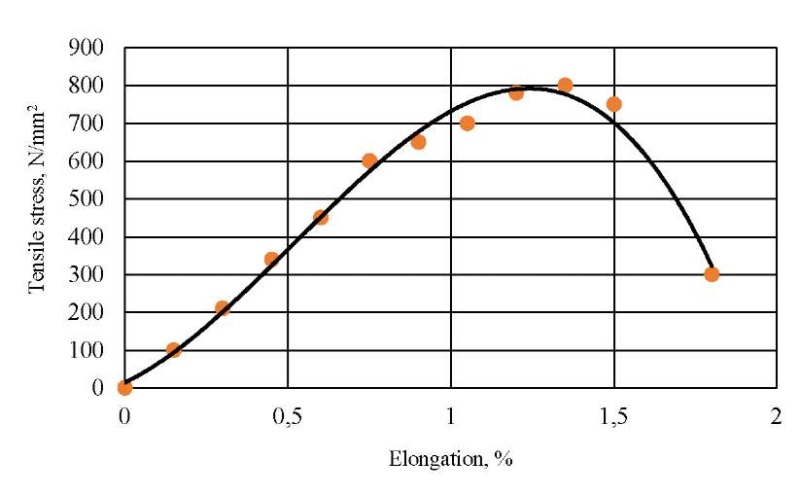

Figure 6 shows the results of tensile testing of glass fiber.

Fig. 6. Behavior of fibers under tension

According to Figure 6, the value of the elastic modulus under tension was calculated. Its average value E = 80,000 MPa, was established, which was accepted for further testing.

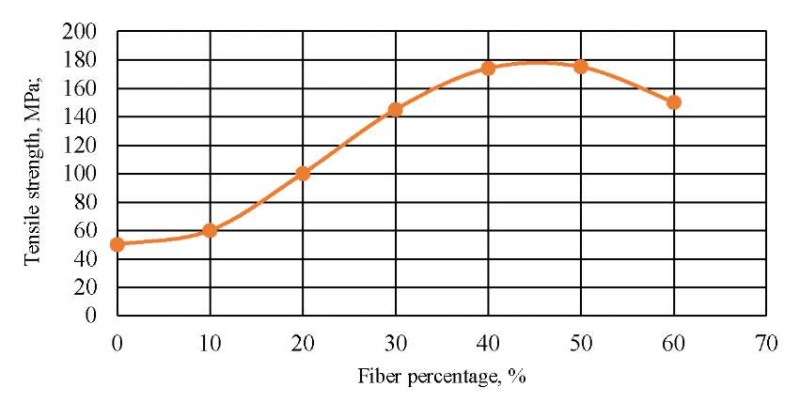

Figure 7 and Table 3 show the results of the effect of the fiber percentage on the strength under tensile tests.

Fig. 7. Fiber percentage effect on the sample strength under tensile testing

The decrease in the value of tensile strength at a fiber content of 60% is due to the fact that polyester becomes insufficient to bind such a mass of fibers. Consequently, the adherence between the base and reinforcing materials is reduced.

Table 3

Tensile strength values depending on the percentage of fiber content

for each sample

|

Fiber content in the sample, % |

Tensile strength values, MPa |

|

0 |

50 |

|

10 |

63.3 |

|

20 |

101.5 |

|

30 |

145.7 |

|

40 |

174.3 |

|

50 |

175.4 |

|

60 |

150.2 |

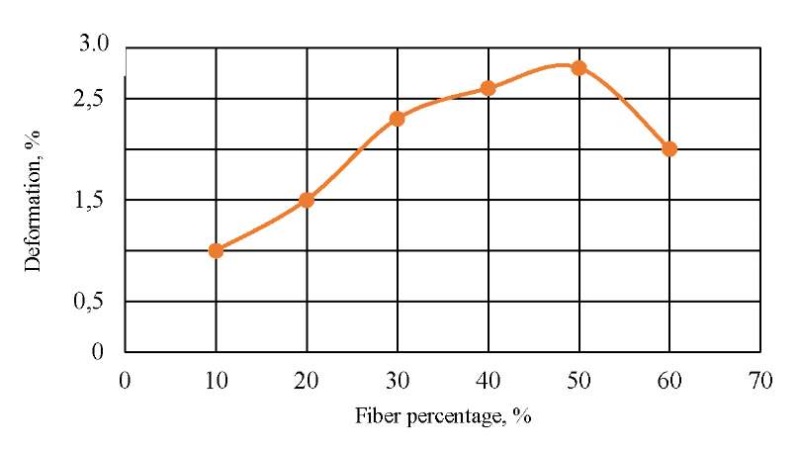

Figure 8 and Table 4 show how the glass fiber content affects the elastic deformation of the samples. It should be noted that with an increase in the fiber content, the elastic deformation index grows and reaches a maximum value (2.71%) at 50%. With a further increase in the mass of the fibers, the elastic deformation decreases, which is due to the high tensile strength of the glass fiber.

Fig. 8. Fiber content effect on elastic deformation

Table 4

Effect of fiber content in samples on elastic deformation

|

Fiber content in samples, % |

Elastic deformation values, % |

|

10 |

1.04 |

|

20 |

1.3 |

|

30 |

2.32 |

|

40 |

2.6 |

|

50 |

2.71 |

|

60 |

2.1 |

Impact tests. The experiments involved a Charpy device in accordance with ISO 1793. Samples with dimensions (80×10×4 mm) similar to those shown in Figure 9 were used.

Fig. 9. Impact test samples

The strength was calculated by dividing the value of the energy expended by the cross-sectional area of the sample:

,

,

where

— impact resistance, J/mm²;

— impact resistance, J/mm²;

— energy expended, J;

— energy expended, J;

![]() — sample cross-sectional area, mm².

— sample cross-sectional area, mm².

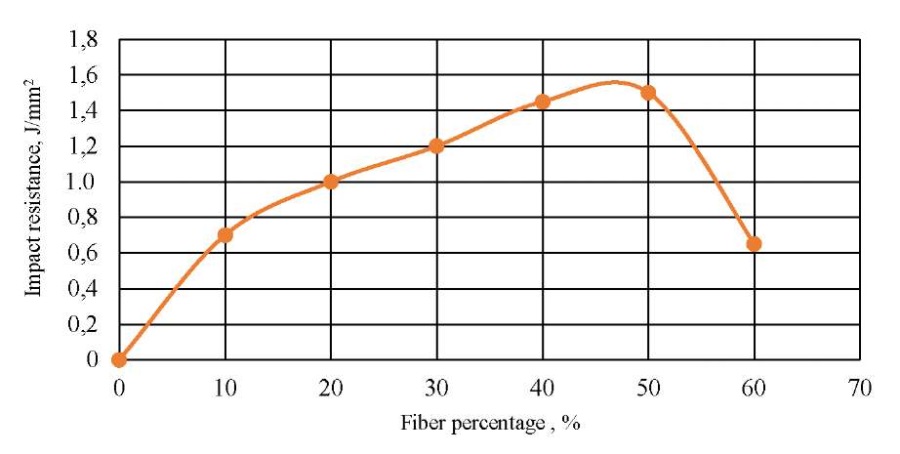

Figure 10 and Table 5 show how the fiber content affects impact resistance.

Fig. 10. Effect of fiber content on impact resistance

Impact resistance increases with a growth of fiber content up to 50%. This is due to the increase in the adherence as a result of the saturation of polyester fibers in the composite material. If the weight of the fibers exceeds 50%, the impact resistance is reduced. This is due to the fragility of the glass [7][13].

Table 5

Effect of fiber content on impact resistance

|

Fiber content in samples, % |

Impact resistance values, J/mm² |

|

10 |

0.75 |

|

20 |

1.27 |

|

30 |

1.37 |

|

40 |

1.45 |

|

50 |

1.56 |

|

60 |

0.7 |

Hardness testing. The hardness of the samples was tested on a durometer, and the Vickers number was calculated by the ratio:

,

,

where

— applied load, kN;

— applied load, kN;

— impact diameter, mm.

— impact diameter, mm.

The tests showed an increase in hardness with a growth of the glass fiber content up to 50 % (Fig. 11 and Table 6).

Fig. 11. Effect of glass fiber content on hardness

Table 6

Effect of fiber percentage on hardness values

|

Fiber content in samples, % |

Hardness values, HV |

|

10 |

23 |

|

20 |

26 |

|

30 |

33 |

|

40 |

37.2 |

|

50 |

38 |

|

60 |

32 |

With a growth of the percentage of glass fiber up to 50%, the hardness of the composite increases. Fibers and polymer chains are connected in a random order. As a result, the penetration resistance of the composite increases, i.e., the hardness [7][13]. If the fiber content exceeds 50%, the hardness is reduced due to the disproportion of fibers and polyester (in this case, it is not enough to complete the connection of the reinforcing and base materials).

It should also be noted that in the course of the study, the inaccuracy of the conclusions in work [14] was proved. Polyester composites with a mass of reinforcing E glass fiber of 15%, 30%, 45%, and 60% were considered. The effect of the glass fiber content on such mechanical properties as tensile and bending strength, impact strength was investigated. The hardness of the composites was evaluated using the Brinell hardness tester. The results showed a significant improvement in the mechanical properties of the composite with an increase in the mass of glass fiber, specifically, at 60%. However, the authors used too wide range of glass fiber content in the composite, which complicated the assessment of the accuracy of the results obtained. In addition, the processes of destruction of fibers were not taken into account, their properties were not checked.

Steel sample testing. In accordance with ASTM4 standard, the samples were made of A36 sheet steel. Tensile, impact and hardness tests were carried out in the same way as for glass fiber reinforced polyester samples.

Table 7 shows the results of mechanical tests of steel samples and their comparison to samples made of composite material with 50% glass fiber (this composite makeup showed the best results).

Table 7

Comparison of the results of mechanical tests of steel samples

and samples made of composite material with a glass fiber content of 50 %

|

Mechanical testing |

Samples made of A36 grade steel |

Samples from composite materials with a glass fiber content of 50 % |

|

Tensile strength, MPa |

400 |

175.4 |

|

Impact resistance, J/mm2 |

0.61 |

1.56 |

|

Elastic deformation, % |

0.11 |

2.71 |

|

Hardness, HV |

135.5 |

38 |

Discussion and Conclusion. Thus, tensile strength of a polyester composite increases significantly with a growth of the mass of glass fiber and reaches a maximum value of 175.4 MPa with a reinforcing material content of 50%. The insignificant content of fibers (they are gradually destroyed) causes the weakness of the composite.

Mechanical characteristics of the material made of 50% polyester and 50% glass fiber are better than those of steel (except for tensile strength). This allows for the use of composite for the production of boats, because in this case, tensile strength is not the basic characteristic [15]. Boats made of unsaturated polyester reinforced with glass fiber are 75% lighter than steel ones. Steel is not resistant to corrosion, which makes composite boats more durable.

The deterioration of the composite quality has been experimentally established if the content of reinforcing fibers exceeds 50%. Two main reasons for this phenomenon are indicated. First: with an excessive mass of glass, its fragility is transmitted to the entire material. Second: with a disproportionately large volume of resin fibers, it is not enough to bond them, which negatively affects the strength.

1. Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics. URL: https://cdn.standards.iteh.ai/samples/3930/2180b1c23fb041fe88bcfd3fba3fe2f6/ASTM-D2343-95.pdf (accessed: 27.09.2023).

2. Standard Test Method for Tensile Properties of Plastics. URL: https://tienda.aenor.com/norma-astm-d638-99-017910 (accessed: 27.09.2023).

3. ISO 179-1:2010. Plastics. Determination of Charpy impact properties. Part 1: Non-instrumented impact test. URL: https://www.gostinfo.ru/catalog/Details/?id=4569214 (accessed: 27.09.2023). (In Russ.)

4. ASTM (American Society for Testing and Materials). The name of a set of standards and an organization in the United States that issues regulations for use in various industries. ASTM standards regulate the chemical composition, mechanical, physical and electrical properties of materials, types of processing, manufacturing methods, testing and testing methods, as well as requirements for rolled metal. URL: https://almet.ru/directory/standards/astm.html (accessed: 27.09.2023). (In Russ.)

References

1. Kumar SN, Kumar VG, Kumar VC, Prabhu M. Experimental Investigation on Mechanical Behavior of E-Glass and S-Glass Fiber Reinforced with Polyester Resin. SSRG International Journal of Mechanical Engineering. 2018;5(5):19–26. https://doi.org/10.14445/23488360/IJME-V5I5P104

2. Bhowmick AK. Mechanical Properties of Polymers. Material Sciences & Engineering. 2016;1:453–461. URL: https://www.eolss.net/sample-chapters/c05/E6-36-01-03.pdf (accessed: 06.09.2023).

3. Hinton MJ, Soden PD, Kaddour AS. (eds) Failure Criterion Fibre-Reinforced-Polymer Composites: The World-Wide Failure Exercise, 1st ed. Amsterdam: Elsevier; 2004. 1269 p.

4. Ravi Jain, Luke Lee. (eds) Fiber Reinforced Polymer (FRP) Composites for Infrastructure Applications. Focusing on Innovation, Technology Implementation and Sustainability. New York, NY: Springer; 2012. 280 p. http://doi.org/10.1007/978-94-007-2357-3

5. Meijer HE, Govaert LE. Mechanical Performance of Polymer Systems: The Relation between Structure and Properties. Progress in Polymer Science. 2005;30(8–9);915–938. http://doi.org/10.1016/j.progpolymsci.2005.06.009

6. Lewin M (ed). Handbook of Fiber Chemistry. International Fiber Science and Technology Series, 3rd ed. Boca Raton, FL: CRC Press; 2006. 1056 p. https://doi.org/10.1201/9781420015270

7. Varga Cs, Miskolczi N, Bartha L, Lipóczi G. Improving the Mechanical Properties of Glass-Fibre-Reinforced Polyester Composites by Modification of Fibre Surface. Materials and Design. 2010;31(1):185–193. https://doi.org/10.1016/j.matdes.2009.06.034

8. Agarwel A, Garg S, Rakesh PK, Singh I, Mishra BK. Tensile Behaviour of Glass Fiber Reinforced Plastics Subjected to Different Environmental Conditions. Indian Journal of Engineering & Materials Sciences. 2010;17(6):471–476. URL: https://nopr.niscpr.res.in/bitstream/123456789/10873/1/IJEMS%2017%286%29%20471-476.pdf (accessed: 06.09.2023).

9. Estabraq T Abdullah. A Study of Bending Properties of Unsaturated Polyester/Glass Fiber Reinforced Composites. Al-Nahrain Journal of Science. 2013;16(3):129–132. http://doi.org/10.22401/JNUS.16.3.18

10. Gornet L. Généralités sur les matériaux composites. Nantes, France: ECN; 2008. 51 р. URL: https://cel.hal.science/file/index/docid/470296/filename/MatComposites.pdf (accessed: 06.09.2023).

11. Noorshashillawati Azura Binti Mohammad. Characterization and Properties of the New Unsaturated Polyester Resins for Composite Application. Gelugor, MYS: School of Industrial Technology; 2007. 125 p. URL: https://core.ac.uk/reader/32600400 (accessed: 06.09.2023).

12. Yilmaz H. Tensile Strength Testing of Thin Spray-on Liner Products (TSLs) and Shotcrete. The Journal of The Southern African Institute of Mining and Metallurgy. 2010;110(10):559–569. URL: http://www.scielo.org.za/pdf/jsaimm/v110n10/01.pdf (accessed: 06.09.2023).

13. Aramide FO, Atanda PO, Olorunniwo OO. Mechanical Properties of a Polyester Fibre Glass Composite. International Journal of Composite Materials. 2012;2(6):147–151. https://doi.org./10.5923/j.cmaterials.20120206.06

14. El-Wazerya MS, El-Elamy MI, Zoalfakar SH. Mechanical Properties Of Glass Fiber Reinforced Polyester Composites. International Journal of Applied Science and Engineering. 2017;14(3):121–131. https://doi.org/10.6703/IJASE.2017.14(3).121

15. Shenoi RA, Dulieu-Barton J, Quinn S. Composite Materials for Marine Applications: Key Challenges for the Future. In book: Nicolais L, Meo M, Milella E. (eds) Composite Materials. London: Springer; 2011. С. 69–89. http://doi.org/10.1007/978-0-85729-166-0_3

About the Author

I. R. AntipasRussian Federation

Imad Rizakalla Antipas, Cand.Sci. (Eng.), Associate Professor of the Fundamentals of Machinery Design Department, ScopusID, ResearchID

1, Gagarin sq., Rostov-on-Don, 344003

Review

For citations:

Antipas I.R. Effect of Glass Fiber Reinforcement on the Mechanical Properties of Polyester Composites. Advanced Engineering Research (Rostov-on-Don). 2023;23(4):387-397. https://doi.org/10.23947/2687-1653-2023-23-4-387-397. EDN: LRSXPY

JATS XML