Scroll to:

Stress Martensite Nucleation in a State of Premartensitic Lattice Instability

https://doi.org/10.23947/2687-1653-2024-24-1-58-65

EDN: KQSXLQ

Abstract

Introduction. The combined effect on the phase transformation process, involving a combination of heat treatment and external action, is a major technology solution for obtaining the required properties of steel products. When hardening steel in a constant magnetic field with a strength of 1–2 MA/m, martensite formation is observed at higher temperatures. In addition, when compared to conventional hardening, there are changes in structure and properties. Such effects cannot be explained only in terms of thermodynamics, since the expected shift in the equilibrium temperature between austenite and martensite in a magnetic field of such strength does not exceed 4–8°C. To explain the effects that occur during hardening in a magnetic field, it is proposed to consider the features of martensitic transformation in highspeed steel when exposed to an external magnetic field in the temperature range of austenite superplasticity. This research was aimed at identifying the features of martensitic transformation in the presence of a constant magnetic field in steel with account for the phenomena occurring in the premartensitic state.

Materials and Methods. Samples made of steel R6M5 were used. Characteristics of the martensitic transformation were studied using the potentiometric method of electrical resistance. The data were recorded using an L-CARD E14-440 analog-to-digital converter with the LGraph2 software package. The sample was heated by passing current. The sample was placed in the interpolar space of an open-type laboratory electromagnet FL-1, which provided the creation of a magnetic field with a strength of 1.2 MA/m.

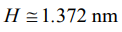

Results. The obtained differentiated dependences were characterized by electrical resistance anomalies (low-temperature peaks) at a temperature corresponding to the appearance of a ferromagnetic phase as a result of martensitic transformation. In a magnetic field, the development of martensitic transformation began at a higher temperature, which could not be explained in terms of thermodynamics. Thus, the formation of stress martensite was observed in microvolumes of austenite with ferromagnetic ordering, which perceived the energy of the external field through magnetostrictive stresses. Under conditions of superplastic austenite, such stresses were sufficient to initiate shear transformation. The minimum possible size of lattice instability fluctuations (1.372 nm) was determined.

Discussion and Conclusion. Exposure to a magnetic field under hardening intensified the processes of some magnetic decomposition of austenite. At temperatures close to the beginning of the martensitic transformation, the existing areas of magnetic inhomogeneity were superimposed on the effects of the phenomenon of instability of the crystal lattice. In the temperature range Md-Mn, when austenite exhibited superplasticity, the formation of stress martensite in microvolumes of austenite with ferromagnetic ordering was significantly facilitated

For citations:

Dolgachev Yu.V., Pustovoit V.N., Vernigorov Yu.M. Stress Martensite Nucleation in a State of Premartensitic Lattice Instability. Advanced Engineering Research (Rostov-on-Don). 2024;24(1):58-65. https://doi.org/10.23947/2687-1653-2024-24-1-58-65. EDN: KQSXLQ

Introduction. Before starting the martensitic transformation, instability of the crystal lattice is detected in metals and alloys [1] expressed in a specific premartensitic state of the initial lattice [2]. The thermodynamic analysis of the state of the initial phase before point Ms [3] shows the possibility of the emergence of separate micro regions having their own short-range ordering in the arrangement of atoms. Such micro regions retain their atomic order only near the fluctuation nucleus. At a distance from it, there are no obvious boundaries between phases, the order gradually degrades. The experimentally described micro regions manifest themselves in the form of diffusion scattering effects during X-ray diffraction. The presence of regions with a near atomic order explains the decrease in elastic constants near point Ms and the convergence of structures [4] involved in the phase transformation.

In the case where an applied external stress is present, the martensitic transformation can be initiated by deformation at a temperature above point Ms. The maximum temperature at which the deformation of the initial phase causes the formation of martensite is indicated by point Md. It has been found [5] that a maximum of plasticity is observed in the temperature range Мd – Ms, which is due to the manifestation of superplasticity associated with the hardening transition. The imposition of a constant magnetic field under these conditions causes the appearance of forced magnetostriction and corresponding stresses in the austenite nanodomains having a ferromagnetic order [6], which induces the appearance of crystals of the hardening phase called stress martensite (by analogy with deformation martensite) [7]. The imposition of a constant magnetic field changes the initial magnetic state of austenite [8], increasing the number and size of ferromagnetically ordered clusters, which are possible sites of nucleation of the ferromagnetic α-phase [6]. Thus, in the temperature range Мd – Ms, the integration of magnetic and a number of special structural states occurs, which is undoubtedly of interest to investigate.

This research was aimed at studying the features of martensitic transformation in the presence of a constant magnetic field in steel taking into account the phenomena occurring in the premartensitic state.

Materials and Methods. In the course of the research, samples of steel P6M5 were used, for which there was information about the development of superplasticity [5] associated with phase transformation [9]. The chemical composition was monitored using a Q8Magellan optical emission spectrometer (Bruker). The average composition of samples from one melt is shown in Table 1.

Table 1

Average content of elements in samples, %

С | Si | Mn | S | P | Cr | Mo | V | W |

0.844 | 0.421 | 0.420 | 0.019 | 0.023 | 3.946 | 4.918 | 2.018 | 5.922 |

To analyze the course of hardening transformation without a field and with the imposition of a magnetic field, the potentiometric method of resistometry was used [10], since changes in the alloy structure were reflected in the measured values ρ with a fairly high sensitivity. And although it is difficult to quantify the relationships between the transforming phases, the establishment of the start and finish points of the transition can be done quite accurately. The applied method is highly sensitive to the appearance of a ferromagnetic phase (during phase transformations of the 1st or 2nd kind), which is shown in abnormal behavior on curve ρ due to electronic interactions at “s” and “d” sublevels [11] determining the presence of spontaneous magnetization [12].

An S-type thermocouple (PTC) was used as a temperature sensor. The thermocouple was spot-welded in the central part of the sample to a single point to eliminate the occurrence of side stresses under separate welding due to the passage of current through the sample during measurement. The data was recorded using an analog-to-digital converter L–CARD E14–440 and the LGraph2 software package. The sample was heated by passing current from the RNO-250–5 autotransformer.

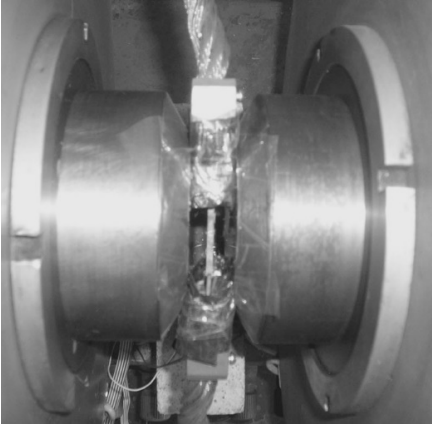

The sample was placed in an interpolar space (Fig. 1). An open-type electromagnet (FL-1) provided the generation of a magnetic field with a strength of 1.2 MA/m. When conducting the experiment without a field, the power supply of the electromagnet was turned off, and the poles were bridged with an ARMCO-iron plate.

Fig. 1. Sample with connected copper contacts in the interpolar space of the magnet

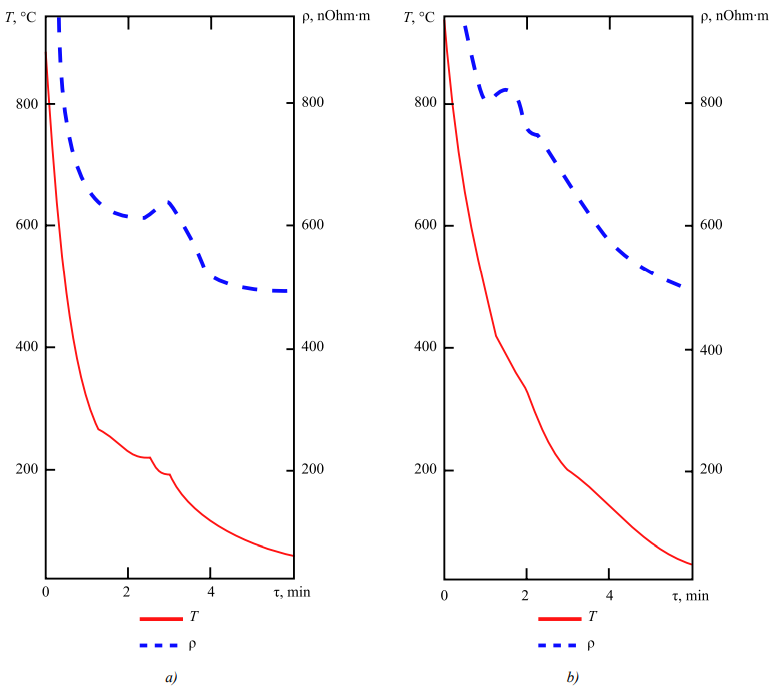

The experimental data (ρ(τ) and Т(τ) in Fig. 2), recorded with a sampling rate of 400 kHz, were numerically differentiated and approximated to obtain function dρ / dT(T), which reflected the characteristic anomalies when a ferromagnetic phase appeared.

Research Results. Primary dependences ρ(τ) and Т(τ) shown in Figure 2 already demonstrate the shift of anomalies, corresponding to the phase transformation, to the high-temperature region when a constant magnetic field is applied.

Fig. 2. Dependences ρ(τ) and T(τ) for steel P6M5 under cooling:

a — without field; b — in magnetic field of 1.2 MA/m

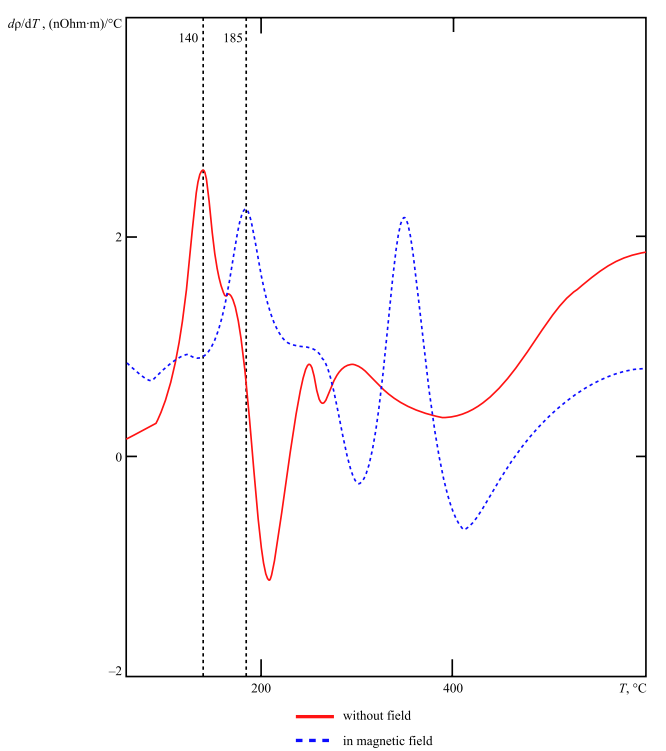

According to the reference data [13], for samples of steel P6M5 corresponding to the chemical composition indicated in Table 1, temperature of 140°C corresponds to the initiation of the martensitic transformation. This is confirmed by the data obtained as a result of differentiation in Figure 3, which illustrate the characteristic features of the analyzed transformation.

The formation of a ferromagnetic phase corresponds to the appearance of a peak at low temperatures (Fig. 3), which makes it possible to record the start of the martensitic reaction. In the case of treatment with the imposition of a magnetic field, the start of the formation of the martensitic phase is noted at a temperature of 185°C, which cannot be explained solely from the point of view of changes in the thermodynamic potentials of the phases. For a magnetic field with a strength of 1.2 MA/m, the effect of the equilibrium temperature shift is ~ 4.5°С [14]. It can be argued that the imposition of a magnetic field in the temperature range of superplasticity causes the formation of stress martensite higher than the starting point of transformation known for this steel as a result of forced magnetostriction in nanodomains with a near magnetic order in austenite. In this case, the stresses arising in the austenitic matrix are about 10 MPa [15], which, under conditions of the crystal lattice instability, contributes to the initiation of a phase reaction.

Fig. 3. Results of differentiation of experimental data obtained under cooling of steel P6M5:

1 — without a field; 2 — in a magnetic field with a strength of 1.2 MA/m

The phenomenon associated with the occurrence of instability of the crystal lattice of the initial phase, as it approaches the transition point, is reflected in the differentiated dependences in the form of a peak in the high-temperature area of the curve. The appearance of this peak under cooling indicates the approach of the superplastic state of austenite. The effect of an external magnetic field enhances the magnetic decomposition of austenite [8], contributing to an increase in the number and size of ferromagnetic nanoclusters [15], which causes a shift of this peak to higher temperatures. Anisotropic fields arise in local regions with unidirectional spins. They introduce elastic distortions due to the fact that the magnetization energy differs in different directions — this reduces the stability of γ-phase lattice. The average diameter of a ferromagnetic nanocluster determined in [8] is about 1.7 nm for a given field strength, which is comparable to the wavelengths of electrons. It can deflect them and, accordingly, cause distortions in the curves. The results obtained indicate the presence of heterogeneity in the magnetic state of austenite, and that this heterogeneity increases when an external magnetic field is applied.

The transformation under hardening is characterized by a diffusionless shear mechanism of atomic restructuring; therefore, external action increases the driving force of the transition. In a state where the lattice of the initial phase becomes unstable before point Ms, spontaneous atomic displacements occur in local regions (preparing the lattice for γ→α transition), where magnetostrictive stresses can act as a trigger for the start of the transformation.

The conditions describing the possibility of fluctuations of atomic displacements in the premartensitic state were considered in [16]. The type of function, whose minimum corresponded to the transition state, was derived on the basis of diffuse scattering patterns and existing options for restructuring the crystal lattice. Oscillation frequencies and anharmonicity parameters were expressed in terms of elastic modulus, whose values determined the adjustment option.

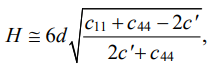

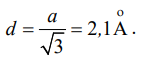

The analysis suggests that micro regions of atomic displacements are shaped like plates of densely packed planes that can experience shear. The expression for estimating the minimum possible fluctuation size H can be derived using matrix elasticity coefficients:

(1)

(1)

where d — interplanar spacing; c′ = 1/2(c11 – c12) — elastic constant; c11, c12, c44 — elastic coefficients.

Values for calculation according to formula (1) were selected for the temperature of martensitic transformation in steel P6M5. Lattice constant a was estimated taking into account the instructions in [17]. The interplanar spacing was determined for the case of a FCC lattice, when the first reflecting planes were a family of planes {111}, having the maximum interplanar spacing  Based on the data on the elastic characteristics of steel P6M5 [9], the elasticity coefficients and constant were determined through known ratios [18]. The calculation results based on dependence (1) allow us to estimate the minimum diameter of the region where instability

Based on the data on the elastic characteristics of steel P6M5 [9], the elasticity coefficients and constant were determined through known ratios [18]. The calculation results based on dependence (1) allow us to estimate the minimum diameter of the region where instability  may occur, which is commensurate with the average diameter of a ferromagnetic cluster in austenite.

may occur, which is commensurate with the average diameter of a ferromagnetic cluster in austenite.

Discussion and Conclusion. The following script for the development of martensitic transformation can be assumed. Above point Ms in γ-phase, there are regions with ferromagnetic ordering [15]. If waves of atomic displacements are superimposed in or near these places, then, in the presence of an external magnetic field, under such conditions, forced magnetostriction is able to affect the fields of elastic forces in the crystal lattice and lower the energy barrier for the formation of a critical martensite nucleus.

The experimental results indicate the existence of magnetic heterogeneity in the state of γ-phase, whose degree affects the running of the martensitic transformation. The imposition of a constant magnetic field under quench cooling enhances the existing magnetic inhomogeneity in austenite. Near point Ms, the phenomenon of lattice instability in combination with magnetostrictive effects from the field initiates the appearance of stress martensite crystals. Thus, the effect of intensification of martensitic transformation under hardening in a magnetic field with a strength of 1–2 MA/m can be explained, which is of great importance for the practice of heat treatment of steel.

The research results showed the following. Exposure to a magnetic field under quench cooling made it possible to achieve greater completeness of the martensitic reaction, reducing the amount of residual austenite, whereas the early formation of stress martensite provided its longer presence in the area of elevated temperatures, which contributed to the flow of tempering processes directly under hardening.

References

1. Yongmei M Jin, Yu U Wang, Yang Ren. Theory and Experimental Evidence of Phonon Domains and Their Roles in Pre-Martensitic Phenomena. npj Computational Materials. 2015;1(1):15002. URL: https://www.nature.com/articles/npjcompumats20152 (accessed: 20.11.2023).

2. Muslov SA, Khachin VN, Pushin VG, Chumlyakov YuI. Elastic Properties and Structure of Alloys TiNi-TiFe prior Martensitic Transformations. Letters on Materials. 2015;5(4):420–423. URL: https://lettersonmaterials.com/Upload/Journals/794/420-4231.pdf (accessed: 20.11.2023).

3. Kondratyev VV, Pushin VG, Romanova RR, Tyapkin YuD. Elastic Properties and Stability of FCC Lattices near the Martensitic Transformation Temperature. The Physics of Metals and Metallography. 1977;44(3):468–479. (In Russ.).

4. Estrin EI. Lattice Stability and Martensitic Transformations. In: Proc. Int. Conf. “Martensitic Transformations”. Kiev: Naukova dumka; 1978. P. 29–33. (In Russ.).

5. Gulyaev AP. Superplasticity of Steel. Moscow: Metallurgiya; 1982. 56 p. (In Russ.).

6. Pustovoit VN, Dolgachev YuV. Ferromagnetically Ordered Clusters in Austenite as the Areas of Martensite Formation. Emerging Materials Research. 2017;6(2):249–253. https://doi.org/10.1680/jemmr.17.00042

7. Frolova AV, Tsarenko YuV, Rubanik VV Jr., Rubanik VV, Stolyarov VV. Tensile Strain of Alloys with the Martensitic Transformation under the External Impact. Bulletin of the Russian Academy of Sciences: Physics. 2019;83(10):1289–1293. https://doi.org/10.1134/S0367676519100107

8. Dolgachev YuV, Pustovoit VN. The Model of Austenite Structure State Taking into Account Fluctuations of Magnetic Nature. CIS Iron and Steel Review. 2022;24(2):74–78. URL: https://rudmet.net/media/articles/Article_CIS_2022_24_pp.74-78.pdf (accessed: 20.11.2023).

9. Gvozdev AE. Production of Blanks of High-Speed Tools under Conditions of Superplasticity. Moscow: Mashinostroenie; 1992. 176 p. (In Russ.).

10. Cherepin VT. Experimental Technique in Physical Metallurgy. Kiev: Tekhnika; 1968. 279 p. URL: https://search.rsl.ru/ru/record/01006388994?ysclid=lozixgfkxj355220445 (accessed: 20.11.2023) (In Russ.).

11. Vonsovskiy SV. Magnetism: Magnetic Properties of Dia-, Para-, Ferro-, Antiferro-, and Ferrimagnets. Moscow: Nauka; 1971. 1032 p. URL: https://search.rsl.ru/ru/record/01007305776?ysclid=lozipmaxya147070803 (accessed: 20.11.2023) (In Russ.).

12. Livshits BG, Kraposhin VS, Linetskii YaL. Physical Properties of Metals and Alloys. Moscow: Metallurgiya; 1980. 320 p. (In Russ.).

13. Popova LE, Popov AA. Diagrams of the Transformation of Austenite in Steels and beta Solution in Titanium Alloys. 3rd ed., reprint. and add. Moscow: Metallurgiya; 1991. 411 p. (In Russ.).

14. Krivoglaz MA, Sadovskiy VD, Smirnov LV, Fokina EA. Hardening of Steel in a Magnetic Field. Monograph. Moscow: Nauka; 1977. 120 p. URL: https://www.imp.uran.ru/?q=ru/content/zakalka-stali-v-magnitnom-pole (accessed: 20.11.2023) (In Russ.).

15. Pustovoit VN, Dolgachev YuV. Magnetic Heterogeneity of Austenite and Transformations in Steels. Monograph. OV Kudryakova (ed). Moscow: IPR Media; 2022. 190 p. https://doi.org/10.23682/117033 (In Russ.).

16. Kondratyev VV, Tyapkin YuD. Elastic Properties and Quasi-Static Displacements of Atoms near the Point of Martensitic Transformation. In: Proc. Int. Conf. “Martensitic Transformations”. Kiev: Naukova dumka; 1978. P. 43–46. URL: https://search.rsl.ru/ru/record/01007789971?ysclid=loziaf1a8v964754252 (accessed: 20.11.2023) (In Russ.).

17. Seki I, Nagata K. Lattice Constant of Iron and Austenite Including Its Supersaturation Phase of Carbon. ISIJ International. 2005;45(12):1789–1794. https://doi.org/10.2355/isijinternational.45.1789

18. Elmanov GN, Zaluzhnyi AG, Skrytnyi VI, Smirnov EA, Perlovich YuA, Yal'tsev VN. Physical Materials Science: Vol. 1. Solid State Physics. 3rd ed., reprint. Moscow: National Research Nuclear University MEPHI; 2021. 764 p. (In Russ.).

About the Authors

Yu. V. DolgachevRussian Federation

Yuri V. Dolgachev, Cand.Sci. (Eng.), Associate Professor of the Materials Science and Technology of Metals Department

1, Gagarin sq., Rostov-on-Don, 344003

V. N. Pustovoit

Russian Federation

Viktor N. Pustovoit, Dr.Sci. (Eng.), Professor of the Materials Science and Technology of Metals Department

1, Gagarin sq., Rostov-on-Don, 344003

Yu. M. Vernigorov

Russian Federation

Yuri M. Vernigorov, Dr.Sci. (Eng.), Professor of the Physics Department

1, Gagarin sq., Rostov-on-Don, 344003

Review

For citations:

Dolgachev Yu.V., Pustovoit V.N., Vernigorov Yu.M. Stress Martensite Nucleation in a State of Premartensitic Lattice Instability. Advanced Engineering Research (Rostov-on-Don). 2024;24(1):58-65. https://doi.org/10.23947/2687-1653-2024-24-1-58-65. EDN: KQSXLQ