Scroll to:

Study on Operating Modes of a Biofuel Diesel Engine

https://doi.org/10.23947/2687-1653-2025-25-2-91-98

EDN: OUWFGB

Abstract

Introduction. Modern research aimed at reducing emissions of harmful substances resulting from the operation of diesel engines using alternative fuels emphasizes their importance and relevance. This topic is becoming increasingly significant in the context of global environmental changes. The development and implementation of alternative energy sources not only contribute to improving air quality, but also help reduce dependence on fossil fuels. Therefore, it is important to continue investing in research and new technologies that will provide for cleaner and more efficient use of resources. There are numerous such studies, specifically, theoretical ones, conducted in European and Asian countries. However, there are practically no experimental works devoted to hemispherical combustion chambers of Russian diesel engines, whose rotation speed, compression ratio and other design parameters differ significantly from similar characteristics described in known studies. In addition, there are practically no experiments devoted to the combustion process of Russian diesel engines with an undivided hemispherical combustion chamber in the piston, which determines the complexity of the volumetric-film mixing process. The research objective is an experimental study of the power and economic indicators, parameters of the combustion process of a diesel engine with an undivided hemispherical combustion chamber in the piston, running on ethanol and rapeseed oil (RO). The study is aimed at establishing dependences showing the effect of various engine operating modes on the specified indicators in order to determine their numerical characteristics.

Materials and Methods. The diesel engine was started using rapeseed oil, after which the ethanol supply was switched on, replacing the rapeseed oil until the set optimum value was reached. The increase in the operating load mode was provided through regulating the ethanol supply. An additional high-pressure fuel pump (HPFP) 2UTNM was installed to supply rapeseed oil, and ethanol was supplied through the standard fuel supply system.

Results. The indicators of the combustion process of a diesel engine running on ethanol and rapeseed oil differ from its regular diesel engine. When working with ethanol and rapeseed oil, an increase in the ignition delay period is noted, which affects the “rigidity” of the combustion process and results in a growth of Pz value. These factors are most likely the main limitations for the use of ethanol by direct injection. One of the solutions to this problem, proposed in this paper, is the use of ignition (pilot) rapeseed oil, which makes it possible to adjust parameters of the combustion process through controlling the amount of ignition fuel supply.

Discussion and Conclusion. The results of the conducted experimental study confirm the possibility of complete replacement of petroleum motor fuel in a diesel engine with an undivided hemispherical combustion chamber in the piston with an alternative (renewable) fuel. This undoubtedly solves important issues of environmental safety of diesel engines. The research results may be useful both to scientists working on this topic, and to engineers and technicians in the machine-building industry.

Keywords

For citations:

Likhanov V.A., Lopatin O.P. Study on Operating Modes of a Biofuel Diesel Engine. Advanced Engineering Research (Rostov-on-Don). 2025;25(2):91-98. https://doi.org/10.23947/2687-1653-2025-25-2-91-98. EDN: OUWFGB

Introduction. In the short and long terms, sustainability and environmental safety issues in the mechanical engineering industry will remain crucial [1]. For example, within the framework of the program package, the European Council has set itself the goal of reducing carbon dioxide emissions by at least 55% by 2030 compared to 1990, and achieving zero CO2 emissions by 2050. According to the latest forecasts, by 2040, about 75% of the 1.6 billion passenger cars on the road will be either internal combustion engine (ICE) vehicles or ICE hybrid vehicles [2]. Hybrid powertrains, both with high and low electrification, combined with modern internal combustion engines, can indeed provide significant benefits in various markets, including the environmental sphere [3]. However, today, the electrification of vehicles remains a challenging task due to numerous real and perceived factors. These factors include limited range, irregular charging infrastructure, regional availability of fully renewable energy sources, demand constraints, and challenges related to the mining and processing of rare earth and precious metals [4]. For light-duty freight applications, electrification may be considered an acceptable alternative to ICE, but it still has a carbon footprint [5].

The approaches to environmental safety in the mechanical engineering industry discussed above fit organically only in the long-term perspective. As a result, a transition to the use of low-carbon or carbon-free fuel is planned [6]. As for the near future and the internal combustion engines currently operating on traditional petroleum motor fuel [7], it is important to discuss the possibility of using alternative fuels both from the point of view of environmental safety and in the context of replacing petroleum-based fuels [8]. We believe that the mechanical engineering industry, being one of the main sources of atmospheric pollution, requires fundamental changes in approaches to fuel use [9]. In order to implement structural changes aimed at improving environmental parameters in mechanical engineering, original equipment manufacturers and their partners should consider the possibility of technological breakthroughs in the modernization of existing ICE [10] and the creation of low-emission vehicles [11][12].

Given the high relevance of using alternative fuels in diesel power units, this circumstance forces the leading machine builders to consider the development of technologies that facilitate the use of various alternative fuels in diesel engines (DE) [13]. The search for new methods and promising technologies aimed at improving the environmental and energy performance of diesel power units, as well as the study on the competition of various types of fuel (diesel fuel, biofuel, natural gas, alcohols, emulsions, etc.) in terms of environmental efficiency can be a significant step towards activating the development and use of alternative motor fuels [14]. The transition to alternative fuels that are not petroleum products will be the most promising direction in the fight to improve the environmental performance for both diesel engines and vehicles in the engineering industry [16].

The most promising in terms of improving the environmental safety of DE are alcohols and vegetable oils [17]. Specifically, when considering alcohols, preference is given to ethanol, which meets the criteria of availability, ease of production and, most importantly, environmental friendliness during combustion [18]. From the authors’ point of view, vegetable oils are of the greatest interest, among which rapeseed oil (RO) is the leader, having excellent technical characteristics, such as high energy density and good fluidity at low temperatures [19].

To date, numerous relevant scientific works have been conducted aimed at improving the environmental safety of diesel engines using alcohols and vegetable oils as motor fuel [20]. However, it should be noted that the analysis of the scientific research results demonstrates the lack of sufficient experimental tests of diesel power units with a working volume of up to 5 liters, running on ethanol and vegetable oils, performed taking into account the relationship between NOx, СНx, CO, CO2 and soot content (SC) in exhaust gases [21]. Although these issues have been widely covered in the literature in terms of theory using various modern forms of modeling, the investigation of this problem only from a theoretical point of view does not help to reveal some critical aspects that are important for organizing the workflow of DE when using ethanol and vegetable oils [22].

This work is aimed at an experimental study of the power and economic indicators, as well as the parameters of the combustion process of a diesel engine with an undivided hemispherical combustion chamber in the piston, operating on ethanol and rapeseed oil, with the establishment of dependences of the impact of its operating modes on the specified indicators and the determination of their numerical characteristics.

Materials and Methods. To achieve the set goal, experimental studies of the DE 2Ch 10.5/12.0 were conducted when operating on ethanol and RO. The DE was started on RO, then the ethanol supply was turned on and replaced RO to the set optimal value (cyclic supply was at the level of 13 mg/cycle, which corresponded to an hourly RO consumption of 1.4 kg/h). An increase in the operating load mode was provided by increasing (regulating) the ethanol supply. An additional fuel injection pump was installed to supply RO, and ethanol was delivered through the standard fuel supply system.

To indicate the working process of the DE, the PS-01 pressure sensor was used, the signal from the sensor was sent to the AQ05-A.1.001 signal amplifier, the amplified signal was sent to the PC via the LA-2 USB analog-to-digital converter (ADC). The pressure sensor was installed in a sleeve mounted in the cylinder head, according to the instruction. The signal from the M50 crankshaft position sensor was fed to the ADC without amplification. The obtained data were processed using a special array superposition algorithm, then the combustion process indicators were determined using the obtained averaged indicator diagram by the methods of Central Research Diesel Institute and Central Research Institute of Materials based on the Wiebe theory [23].

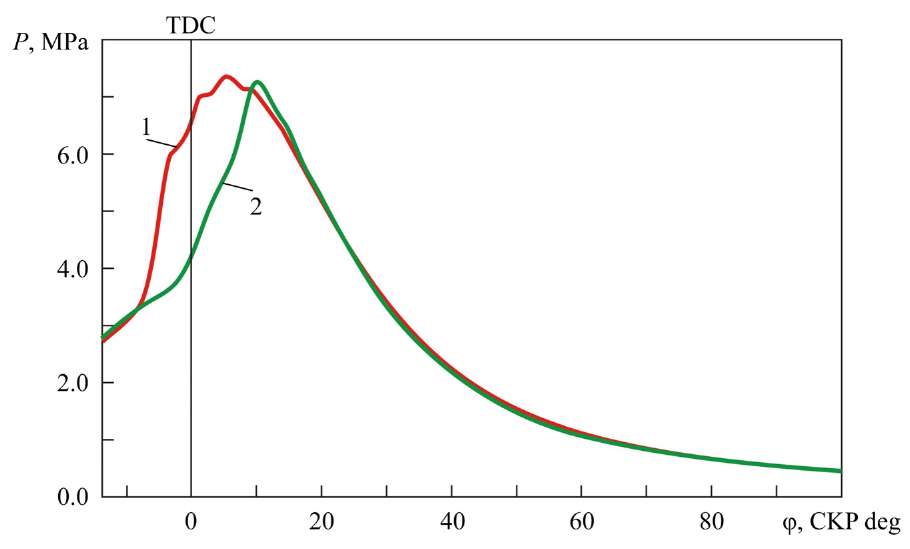

Research Results. Figure 1 shows the results of determining the average indicator diagram for optimal installation angles of fuel injection advance for ethanol and RO, equal to 34° before top dead center (TDC) [15].

Fig. 1. Effect of DE crankshaft angle on the indicator pressure:

1 — DF; 2 — ethanol and RO [22]

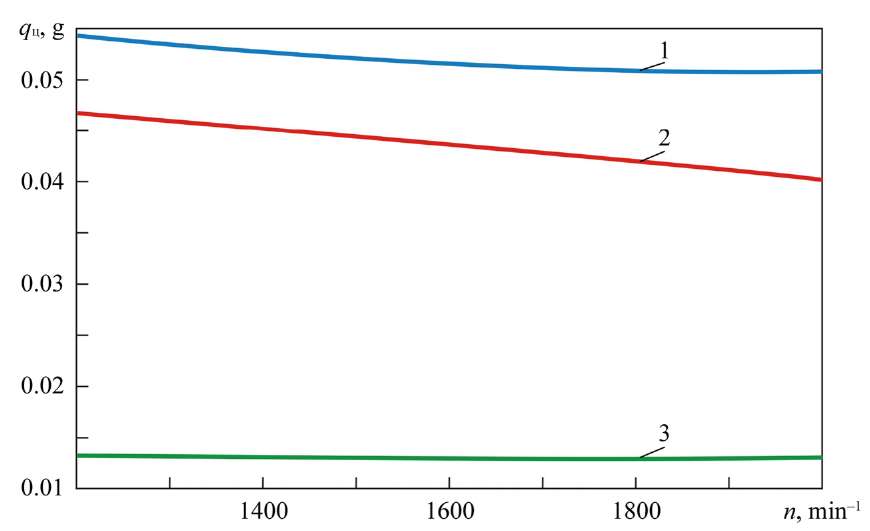

From scientific literature, researchers are well aware of the valuable qualities of the indicator diagram. This direct recording of the actual (indicator) pressure depending on the crankshaft angle clearly demonstrates the value of the physical quantity without the need to perform any calculations. Using the indicator diagram, one can easily understand the dynamics of the working process and obtain valuable information on the amount of the maximum combustion pressure Pz of the ignition delay period (IDP). In addition, the indicator diagram is a visual representation of the dynamics of autoignition in a diesel engine [22]. Thus, the analysis of the indicator diagrams presented in Figure 2 shows that when operating on ethanol and RO, an increase in the IDP is observed, while no significant change in the maximum pressure in the cycle is noted. Since the calorific value of ethanol is lower than that of diesel fuel, it is required to compensate for this difference by increasing the cyclic fuel supply (Fig. 2).

Fig. 2. Cyclic fuel supply: 1 — DF; 2 — ethanol; 3 — RO [11]

Considering the nominal speed mode (n = 1,800 min–1), we note that the RO supply was 13 mg/cycle, while the ethanol supply reached 52 mg/cycle (Fig. 2). In the diesel mode, the cyclic supply was 43 mg/cycle.

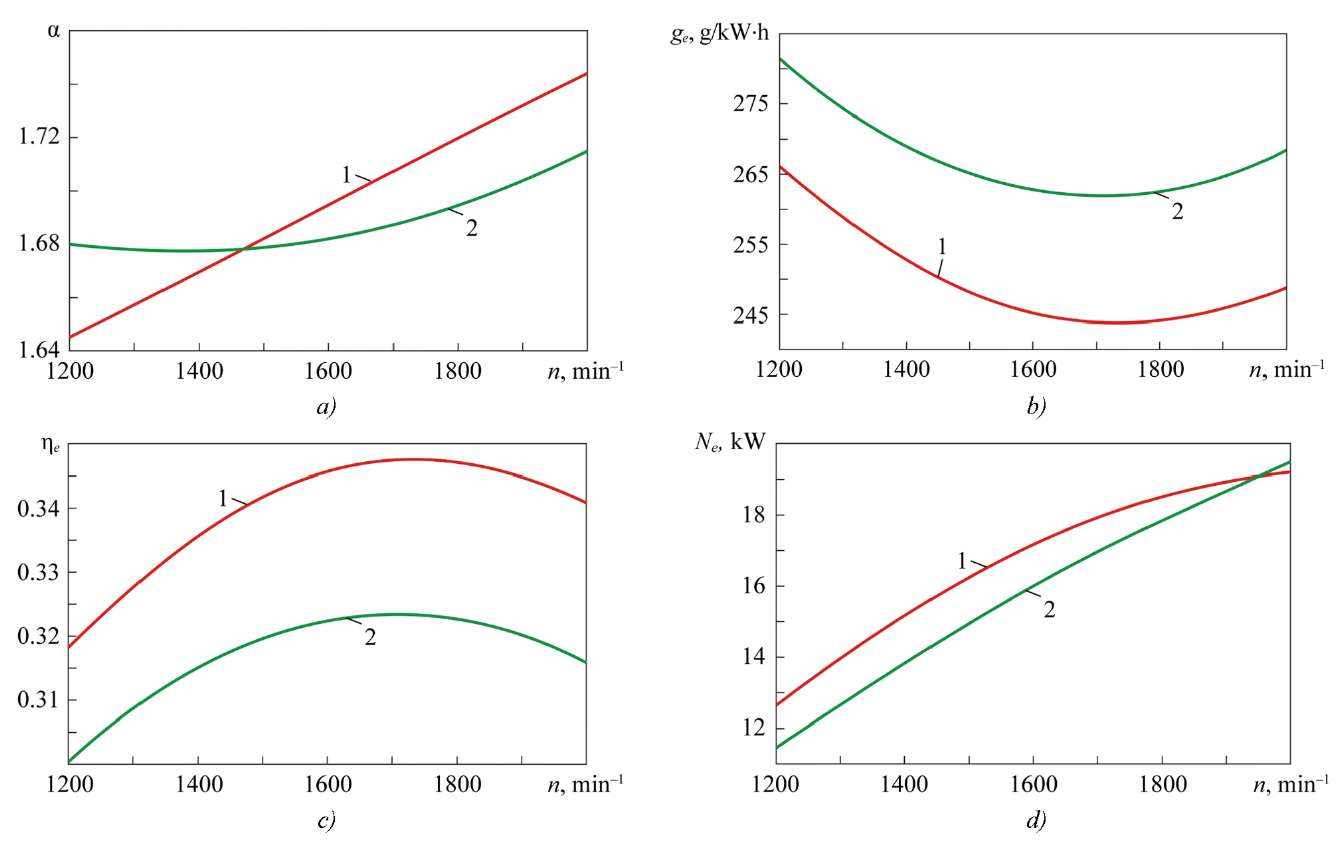

Fig. 3. DE performance:

a — excess air factor;

b — specific effective fuel consumption;

c — effective efficiency;

d — effective power;

1 — DF; 2 — ethanol and RO [11]

When operating on ethanol and RO, an increase in fuel consumption reduces the effective efficiency, specifically at low rotation speeds, which cannot but affect the effective power and leads to some reduction (Fig. 3 d). And at peak values, when the DE operates on ethanol and RO, the power indicators and characteristics of the combustion process (Fig. 4 a) already exceed the DF values.

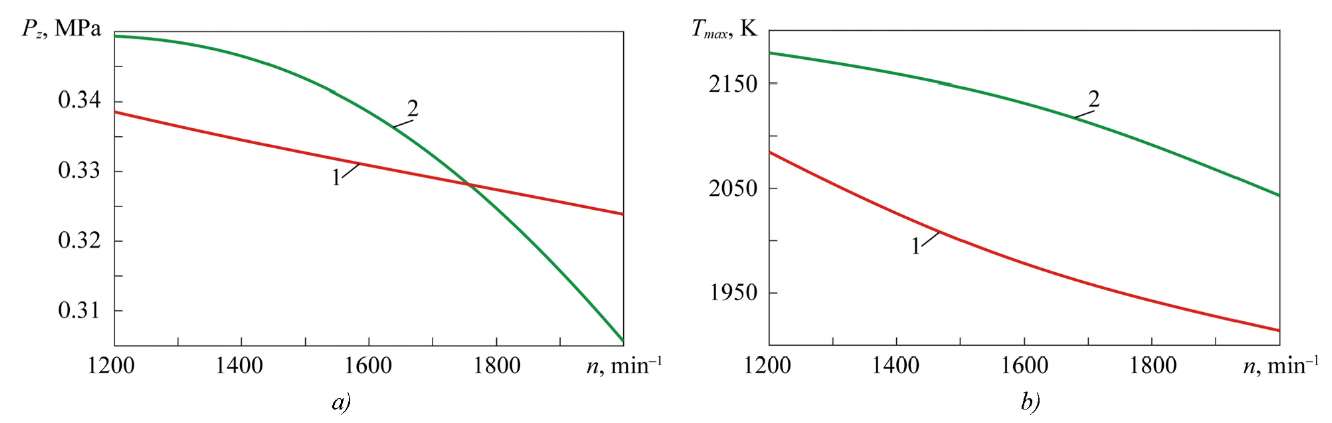

Fig. 4 Indicators of DE combustion process:

a — maximum combustion pressure;

b — maximum average temperature;

1 — DF; 2 — ethanol and RO [15]

Analyzing the graphical dependences shown in Figure 4, it should be noted that at low rotational speeds of the DE operation on ethanol and RO, Pz is equal to 8.2 MPa, and at a lower rotation speed, it is 6.5 MPa. Value Tmax also decreases, but remains higher than the values of the DE operation on DF. Apparently, this growth is due to the higher IDP of the DE when operating on ethanol and RO, since over a longer period of time, a larger amount of fuel evaporates when mixing with air. This, in turn, results in an increase in the intensity of heat release processes in the kinetic phase of combustion and an increase in Tmax with the achievement of its maximum values at later angles. Thus, when DE operates on ethanol and RO, combustion starts later by approximately 4–7 degrees compared to operation on DF [15].

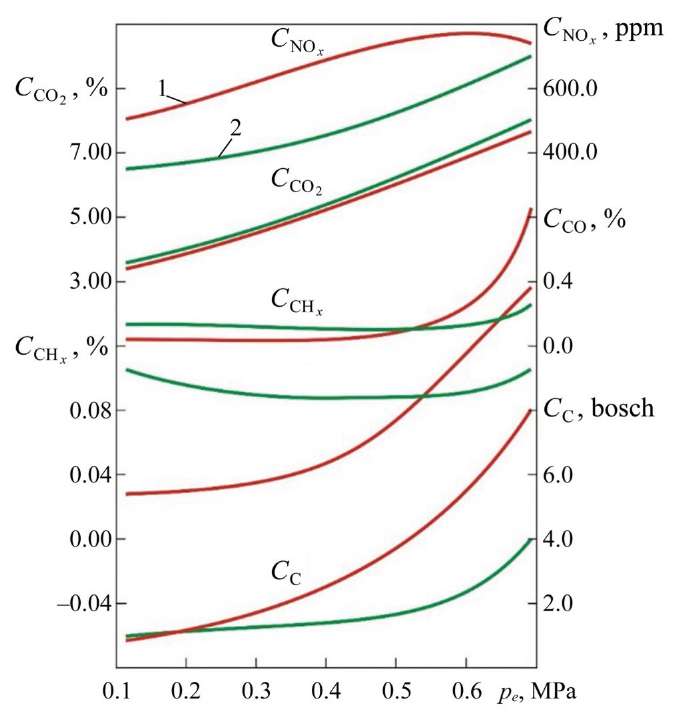

Figure 5 shows the toxicity characteristics of the exhaust gases (EG) of the DE at the nominal speed.

Fig. 5. DE EG toxicity indices (n = 1800 min–1):

1 — DF; 2 — ethanol and RO

The results of experimental studies on the toxicity of DE show that the use of ethanol and RO causes a decrease in the concentration of nitrogen oxides (NOx), carbon dioxide (СО2) and soot (S) in the studied modes. At loads above average, there is a decrease in the concentration of carbon monoxide (СО) and hydrocarbons (СНх).

The numerical values of the results of experimental studies on the toxicity of DE at the nominal operating mode are summarized in Table 1.

Table 1

Results of Studies on Toxicity and Smoke Indicators of DE EG 2Ch 10.5/12.0

When Running on Ethanol and RO (n = 1800 min–1, pе = 0.588 MPa)

|

Fuel |

Indicators |

|||

|

NOx, ppm |

S, ea on Bosch scale |

СНx, % |

СО, % |

|

|

Diesel fuel |

790 |

5.3 |

0.11 |

0.22 |

|

Ethanol +RO |

590 (decrease by 25.3%) |

2.2 (2.4 times decrease) |

0.09 (decrease by 18.2%) |

0,14 (decrease by 36.4%) |

Discussion and Conclusion. Analyzing the obtained results of the considered experimental studies, it should be noted that the combustion process indicators of the DE, working on ethanol and RO, differ from its standard one, working on DF. Especially when using ethanol and RO, an increase in the area of influence zone (IZA) is observed, which cannot but have a significant effect on the “rigidity” of the combustion process and will result in an increase in value Pz. These arguments are likely to be the main restraining factors for the use of ethanol by direct injection. One of the possible solutions to the problem, proposed in this paper, is the use of pilot RO, which allows the combustion process parameters to be adjusted through controlling the amount of pilot fuel supplied. It should be explained that the pilot RO value was changed to a certain value (indicated above in the paper), at which the required combustion parameter characteristics were obtained. After that, the RO value was fixed, and the change in the DE load modes was provided by the required ethanol supply. It is clear to experts that this solves the problem only in a particular case. In further research, it will be necessary to implement dynamic adjustment of both the RO ignition portion value and the fuel injection advance angle. This will facilitate further optimization of the fuel supply system, and the organization of the combustion process as a whole. Nevertheless, to sum up, we note that this work has solved the issues of improving the operational characteristics of DE by using biofuel with the establishment of characteristic dependences of the impact of operating modes on efficiency and the determination of their numerical values. Moreover, the effectiveness of the proposed solution is confirmed by the complete replacement of petroleum motor fuel with alternative (renewable) one.

References

1. Kavtaradze RZ, Onischenko DO, Golosov AS, Zelentsov AA, Chen Zh, Sakhvadze GZh. The Influence of the “Piston Heat Belt–Sleeve” Gap on Heat Exchange in the Combustion Chamber of an Engine Depending on the Fuel Utilized. Journal of Machinery Manufacture and Reliability. 2022;51(2):112–120. https://doi.org/10.3103/S1052618822010046

2. Kulagin V, Grushevenko D, Galkina A. Global and Russian Energy Outlook Up to 2050. Contemporary World Economy. 2024;2(1):6–22. https://doi.org/10.17323/2949-5776-2024-2-1-6-22

3. Sens M. Hybrid Powertrains with Dedicated Internal Combustion Engines are the Perfect Basis for Future Global Mobility Demands. Transportation Engineering. 2023;13:100146. https://doi.org/10.1016/j.treng.2022.100146

4. Beltrami D, Iora P, Uberti S, Tribioli L. Electrification of Compact Off-Highway Vehicles – Overview of the Current State of the Art and Trends. Energies. 2021;14(17):5565. https://doi.org/10.3390/en14175565

5. Vokhmin DM, Kozin ES. Basics of Monitoring the Carbon Footprint of Traffic Flows in Large Cities. Transport: Science, Equipment, Management. Scientific Information Collection. 2024;(6):11–17.

6. Fangyuan Zheng, Haeng Muk Cho. The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines. Energies. 2024;17(2):344. https://doi.org/10.3390/en17020344

7. Mateichyk V, Kryshtopa S, Kryshtopa L, Smieszek M, Kostian N, Mosciszewski J, et al. Research of Energy Efficiency and Environmental Performance of Vehicle Power Plant Converted to Work on Alternative Fuels. Machines. 2024;12(5):285. https://doi.org/10.3390/machines12050285

8. Markov VA, Devyanin SN, Bowen Sа, Normurodov AA. Investigation of the Operation of a Diesel Engine on Blended and Emulsified Biofuels with Rapeseed Oil Additives. Dvigatelestroyeniye (Engines Construction). 2023;291(1):70–90. https://doi.org/10.18698/jec.2023.1.70-90

9. Keunsang Lee, Haeng Muk Cho. Effects of Castor and Corn Biodiesel on Engine Performance and Emissions under Low-Load Conditions. Energies. 2024;17(13):3349. https://doi.org/10.3390/en17133349

10. Kavtaradze RZ, Kondratev AM, Rongrong Ch, Citian Ch, Baigang S, Sakhvadze GZh. Local Heat Exchange in the Combustion Chamber of a Hydrogen Engine Running on a Lean Fuel Mixture. Journal of Machinery Manufacture and Reliability. 2021;50(1):79–87. https://doi.org/10.3103/S105261882101012X

11. Likhanov VA, Lopatin OP. High-Speed Operation Modes of a Biofuel Diesel Engine. Dvigatelestroyeniye (Engines Construction). 2024;296(2):75–83.

12. Rathinavelu V, Kulandaivel A, Pandey AK, Bhatt R, De Poures MV, Hossain I, et al. Production of Green Hydrogen from Sewage Sludge/Algae in Agriculture Diesel Engine: Performance Evaluation. Heliyon. 2024;10(1):e23988. https://doi.org/10.1016/j.heliyon.2024.e23988

13. Zheliezna T, Drahniev S. Comparative Analysis of Biodiesel and Renewable Diesel as Motor Fuels. Journal of Science. Lyon. 2024;57:34–39. https://doi.org/10.5281/zenodo.13694682

14. Kovbasenko S. Possibilities of Enhancing the Environmental Safety of Diesel Vehicles Using Alternative Fuels. Journal of Mechanical Engineering and Transport. 2023;16(2):51–57. https://doi.org/10.31649/2413-4503-2022-16-2-51-57

15. Likhanov VA, Lopatin OP. Research of the Combustion Process in a Tractor Diesel Engine When Operating on Alcohol and Vegetable Oil. Tractors and Agricultural Machinery. 2023;90(3):191–200. https://doi.org/10.17816/0321-4443-320931

16. Jurj S, Werner T, Grundt D, Hagemann W, Möhlmann E. Towards Safe and Sustainable Autonomous Vehicles Using Environmentally-Friendly Criticality Metrics. Sustainability. 2022;14(12):6988. https://doi.org/10.3390/su14126988

17. Lindemberg De Jesus Nogueira Duarte, Gilson Medeiros, Humberto Neves Maia De Oliveira, Eduardo Lins De Barros Neto, Rayandson Raimundo Da Silva, Jessyca Bezerra. Evaluation of the Effect of Ethyl Alcohol Content in a Ternary Ethanol/Biodiesel/Diesel System. International Journal of Thermodynamics. 2024;27(2):19–26. https://doi.org/10.5541/ijot.1372558

18. Krakowski R, Witkowski K. Investigating the Effects of Environmentally Friendly Additives on the Exhaust Gas Composition and Fuel Consumption of an Internal Combustion Engine. Applied Sciences. 2024;14(7):2956. https://doi.org/10.3390/app14072956

19. Doluda VYu, Laskina NV, Brovko RV, Sulman MG. Investigation of Optimal Physico-Chemical Parameters of the Catalytic Transformation of Ethanol and Isopropanol into Aromatic Hydrocarbons. Herald of TvSU. Series: Chemistry. 2024;57(3):76–85. https://doi.org/10.26456/vtchem2024.3.7

20. Krivenko DA, Logvinov AYu, Ishkov AV. Investigation of Operating Process of Automotive Diesel Engines of the Minsk Motor Plant in Maximum Power Mode Using Alternative Biofuel. Bulletin of Altai State Agricultural University. 2024;233(3):75–84. https://doi.org/10.53083/1996-4277-2024-233-3-75-84

21. Tsapenkov KD, Kuraeva YuG, Sidorova EI, Shtyrlov AE, Zubrilin IA. Effect of Fuel Composition on Soot Formation in Engines and Power Plants. Combustion, Explosion and Shock Waves. 2024;60(4):63–75. https://doi.org/10.15372/FGV2023.9430

22. Likhanov VA, Lopatin OP. Investigation of Carbon-Black Emissions of a Tractor Biofuel Diesel. Tractors and Agricultural Machinery. 2024;91(4):375–385. https://doi.org/10.17816/0321-4443-625783

23. Likhanov VA, Kozlov AN, Araslanov MI. Investigation of the Portion Size of Rapeseed Oil for Ethanol Ignition in a Diesel Engine. IOP Conference Series: Earth and Environmental Science. 2020;548:62053. https://doi.org/10.1088/1755-1315/548/6/062053

About the Authors

V. A. LikhanovRussian Federation

Vitaly A. Likhanov, Dr.Sci. (Eng.), Professor, Head of the Department of Thermal Engines of Automobiles and Tractors

133, Oktyabrsky Ave., Kirov, 610017

O. P. Lopatin

Russian Federation

Oleg P. Lopatin, Dr.Sci. (Eng.), Associate Professor, Professor of the Department of Thermal Engines of Automobiles and Tractors

133, Oktyabrsky Ave., Kirov, 610017

The paper examines the power and economic indicators of a diesel engine. It is shown that operation on ethanol and rapeseed oil changes combustion parameters. An increase in the ignition delay period affects the stability of the process. The use of pilot (rapeseed) oil is proposed to solve the identified problems. The results confirm the possibility of replacing petroleum fuel with alternative energy sources.

Review

For citations:

Likhanov V.A., Lopatin O.P. Study on Operating Modes of a Biofuel Diesel Engine. Advanced Engineering Research (Rostov-on-Don). 2025;25(2):91-98. https://doi.org/10.23947/2687-1653-2025-25-2-91-98. EDN: OUWFGB