Scroll to:

Liquid temperature effect on the hydraulic shock wave velocity in polyethylene pipes

https://doi.org/10.23947/2687-1653-2021-21-4-319-327

Abstract

Introduction. Providing people with high quality drinking water has always come first. However, its transportation through pipeline systems was often associated with some problems, such as the temperature of the water and the environment, as well as the possibility of water hammer on certain pipe sections. This was especially true for systems that use polyethylene pipes. Temperature is a key factor affecting the flexibility properties of polyethylene pipes, and it affects not only the design, but also the investment in the development of water supply networks. The purpose of these studies was to study the effect of water and ambient temperature on the density, properties of the pipe material and the speed of propagation of a hydraulic shock wave in polyethylene pipes.

Materials and Methods. In the experiments performed, the method of field research was used, when tests are carried out on specialized equipment on samples specially made for the pursued purposes. Here, samples of high-density polyethylene pipes were used, which were subjected to tensile tests on a tensile testing machine, and each experiment was carried out three times.

In the course of the experiments, the samples were exposed to certain temperature regimes (both external and internal), while the influence of the hydrodynamic pressure of the liquid in the pipe was also investigated, as a result of the change in time of the liquid velocity in its sections. To do this, the samples were supplied with liquid under a certain pressure in order to find out the influence on the pipes of an effect known as water hammer.

Results. In the course of the research, it was found that the value of the elastic modulus of high-density polyethylene PE100 decreases with increasing water temperature, and the decrease at a temperature of 60° C reaches 60.21% compared to its value at a water temperature of +4° C. Based on the results of experiments to determine the effect of the elastic modulus of polyethylene with increasing temperature, an exponential equation was derived to calculate the value of the polyethylene coefficient as a function of time E = 1.312e-0,01t with the correlation coefficient R2 = 0.988 ; and based on the results of the studies carried out to calculate the value of the propagation velocity of a hydraulic shock wave, an exponential equation was derived as a function of time C = 275.9e-0,01t with the coefficient correlation R2 = 0.987 .

Discussion and Conclusions. In the course of the research, it was found that such a phenomenon as water hammer has a harmful effect on the pipe walls, which, if possible, should be avoided even at the design stage of the water supply network. During the experiments, it was found that with an increase in temperature, the values of the elastic modulus of polyethylene decreased with a simultaneous decrease in the values of the propagation velocity of the hydraulic shock wave.

For citations:

Antypas I.R., Dyachenkо A.G., Imad S.B. Liquid temperature effect on the hydraulic shock wave velocity in polyethylene pipes. Advanced Engineering Research (Rostov-on-Don). 2021;21(4):319-327. https://doi.org/10.23947/2687-1653-2021-21-4-319-327

Introduction. The temperature of the liquid flow and the ambient temperature have a significant impact on the properties of the material of pipes made of high-density polyethylene. As the temperature increases, the pipe material becomes more flexible, which causes a decrease in the hydraulic shock wave propagation velocity, and hence, a decrease in pressure. Manufactured polyethylene pipes made of PE100 (HDPE) are thermoplastics since their plasticity varies within the appropriate limits depending on the operating conditions. These plastics have a number of advantages, including a relatively small specific gravity, they make it possible to work at low temperatures, are able to withstand moderate pressure, have high corrosion resistance (specifically, to acids and alkalis), good electrical insulation properties, are easily painted, and easy to install. They are made immediately in large lengths which reduces the number of connecting elements during their laying; these elements are considered expensive and fragile and cause problems associated with leaks [1–6]. Polyethylene pipes are hydraulically smooth pipes in which the loss of friction energy during the liquid flow is much less than in metal pipes, which leads to saving pumping energy. These pipes are characterized by a very small roughness range (k=0.001-0.008 mm), which is 3-20 times less than the roughness of new steel pipes. Temperature is one of the most important factors affecting the flexibility properties of polyethylene pipes, and this factor not only affects the design and investment in various drinking water supply networks with flow stability, but also causes its unstable flow in the form of a water hammer in polyethylene pipes [7–10]. International standards define the properties of polyethylene pipes in drinking water supply networks at a temperature of 20-23 °C, while the European standards define them at a temperature of 10 °C. At low flow temperatures, the elastic modulus of polyethylene pipes is relatively large compared to high flow temperatures in case of the water hammer phenomenon, which can have a significant impact on the walls of polyethylene pipes in drinking water supply networks [11–14]. The objective of these studies is to explore the influence of liquid temperature and air temperature surrounding polyethylene pipes on the density, other properties of the pipe material, and on the hydraulic shock wave propagation velocity in them.

Research methods and materials. Water hammer. A water hammer is an increase or decrease in the hydrodynamic pressure of a liquid in a pipe as a result of a change in the liquid velocity in its section. This impact can create high pressure, which must be taken into account when calculating the wall thickness of the pipe. The liquid compressibility and the tendency of pipe walls to deform give the water hammer elasticity, since it is presented as pressure waves propagating through the pipe in an unstable flow. There are two types of water hammer:

1. Direct water hammer is dangerous and occurs when the stopping time is less than the hydraulic wave period, tC < t0.

2. Indirect water hammer, which is not dangerous and is triggered when the shutdown time is longer than the hydraulic wave period, tC > t0:

(1)

(1)

where t0 — the hydraulic wave period, s; L — the pipe length, m; Cj — the hydraulic shock wave propagation velocity, m/s; tC — the valve closing or opening time, s.

Direct water hammer occurs when a valve connected to the wide surface of the tank suddenly opens or closes at the end of the pipe, or the power supply to the pumping station suddenly stops. The pressure change as a result of direct water hammer is determined from the Joukowski-Levy ratio:

(2)

(2)

where  Pmax — variation value of high or low pressure, N/m2;

Pmax — variation value of high or low pressure, N/m2;

pj — liquid density at steady flow rate, kg/m3;

Cj — hydraulic shock wave propagation velocity, m/s;

V0 — steady-state velocity of liquid flow in the pipe, m/s.

As for indirect water hammer, it occurs when the valve is slowly opened or closed at the end of the pipe connected to the wide surface of the tank, or when the shutdown time of the pumping group at the pumping station increases. The variation value of the pressure as a result of indirect water hammer is determined from the following ratio:

(3)

(3)

Value Cj is determined from the following ratio of the hydraulic shock wave propagation velocity in polyethylene pipes:

(4)

(4)

where M — constant consolidation at D/e > 40

— for support on one side of the pipe

M =1,25 -  , M =1 -

, M =1 -  /2;

/2;

— to support the entire pipe

M =1 -  2;

2;

— for pipes without support (expansion joints)

М=1,

where  — Poisson's modulus is 0.45 for HDPE pipes [3–4];

— Poisson's modulus is 0.45 for HDPE pipes [3–4];

E0j — water elasticity coefficient, N/m2;

pj — water density, kg/m3; D — pipe inner diameter, m.

The hydraulic shock wave propagation velocity in polyethylene pipes is in the range of 180–370 m/s [1][9].

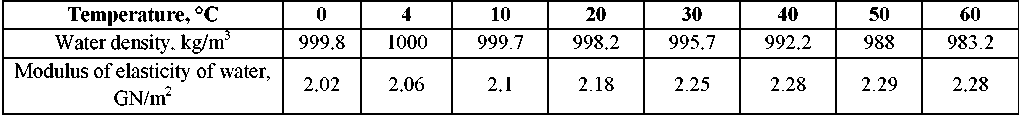

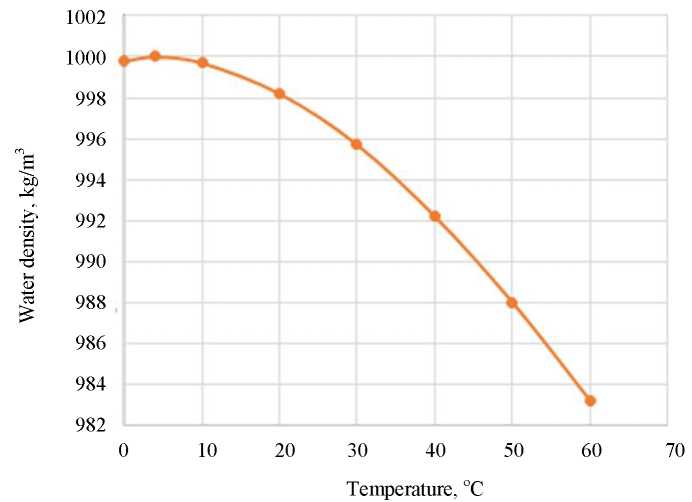

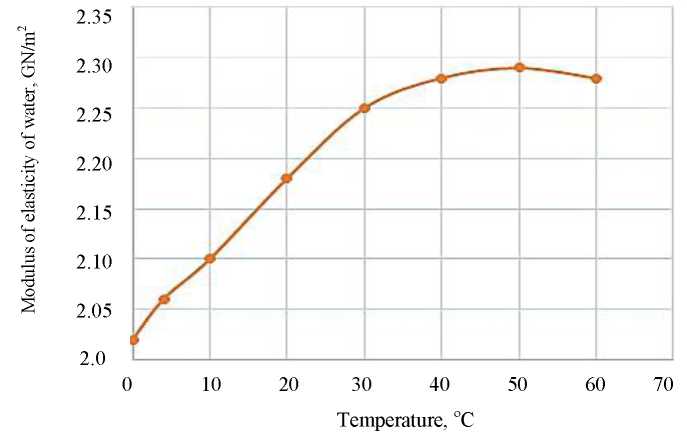

Table 1 presents data on the physical properties of water at atmospheric pressure on its surface. Figure 1 shows a decrease in the water density with an increase in temperature, and Figure 2 shows an increase in the value of the elastic modulus of water with an increase in its temperature.

Table 1

Physical properties of water at atmospheric pressure on its surface

Fig. 1. Change in water density with increasing temperature

Fig. 2. Dependence of the water elastic modulus values on temperature

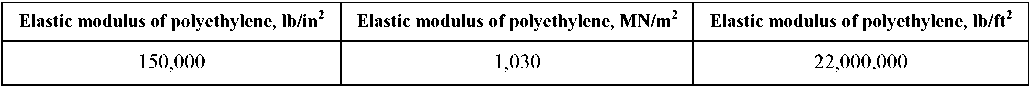

Table 2 shows the elastic modulus of the polyethylene pipe material at 16оC [2][10].

Table 2

Elastic modulus of the polyethylene pipe material at 16оC

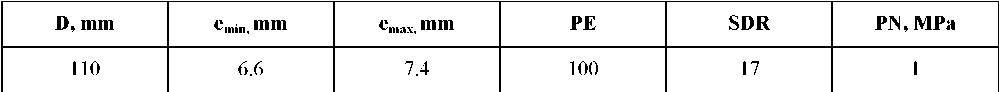

Laboratory experiments. 21 samples in the form of pipes were obtained from one large high-density HDPE polyethylene pipe, some of the characteristics of which are given in Table 3.

Table 3

Specifications of HDPE pipes

To conduct the research, the following actions were performed:

— for each of the specified temperatures, three tensile samples (type ⅼ) were used, and their average value was taken;

— temperature range in 4, 10, 20, 30, 40, 50, 60оС was accepted;

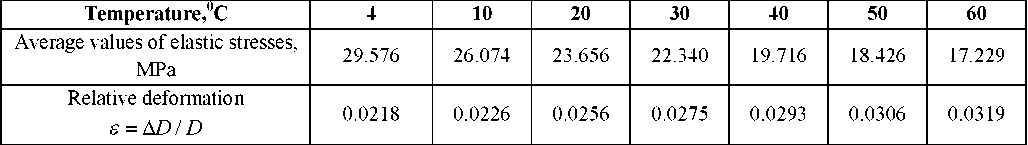

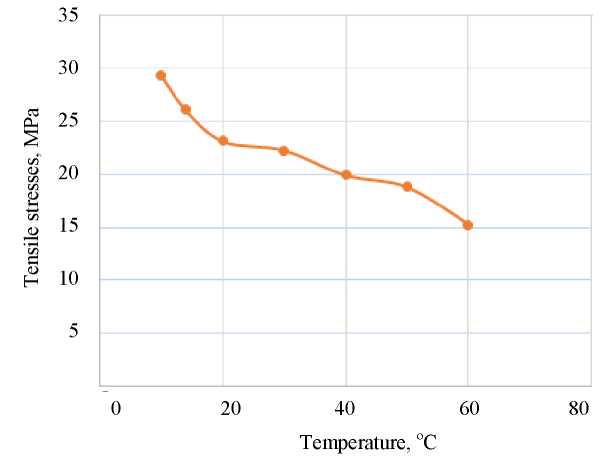

— the tensile samples were heated in accordance with the temperature for one hour in a digital electric furnace, they were then stretched using a special device, the results are shown in Table 4 and in Fig. 3;

— a plastic tube with a diameter of 10 mm was injected with water, whose temperature corresponded to previously specified range, up to the point of rupture, and then relative deformation  =

= D/D was measured, the results are shown in Table 4.

D/D was measured, the results are shown in Table 4.

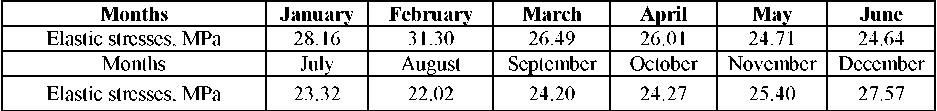

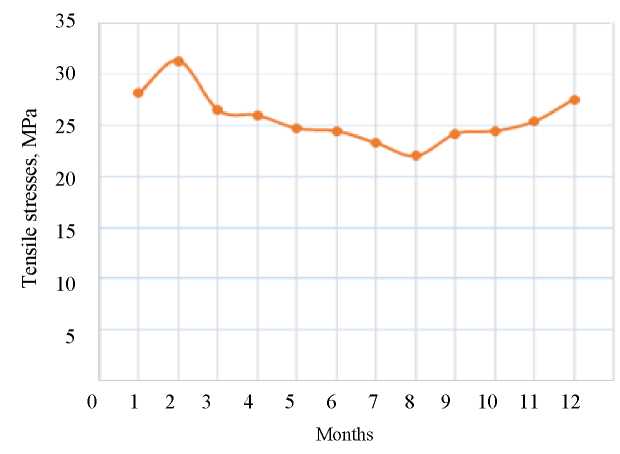

The results of polyethylene samples were taken for a year for a pipe with an external diameter of 110 mm at a nominal pressure of 10 Bar. The results obtained were constantly compared to changes in laboratory temperatures during a year. They are presented in Table 5 and in Fig. 4.

Table 4

Maximum values of elastic tensile stresses and relative deformation of polyethylene samples in accordance with specified temperatures

Table 5

Maximum variation values of elastic tensile stresses for polyethylene samples depending on temperature variation during the year

Fig. 3. Tensile stresses of polyethylene with increasing temperature

Fig. 4. Tensile stress values of polyethylene samples during the year

Results. The results were processed according to Hooke 's law as follows:

=

= D/D=

D/D= /E, (5)

/E, (5)

where  — tensile stress in the pipe wall, MPa; D — pipe diameter, mm;

— tensile stress in the pipe wall, MPa; D — pipe diameter, mm;  D — change in pipe diameter, mm; E — pipe material elasticity expressed by Young's modulus, MPa;

D — change in pipe diameter, mm; E — pipe material elasticity expressed by Young's modulus, MPa;  — relative

— relative

deformation.

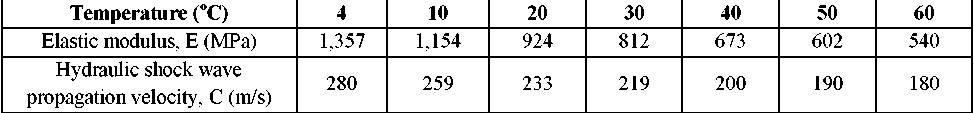

Table 6 shows the elastic modulus values of PE 100 polyethylene and the hydraulic shock wave propagation velocity at the specified temperatures.

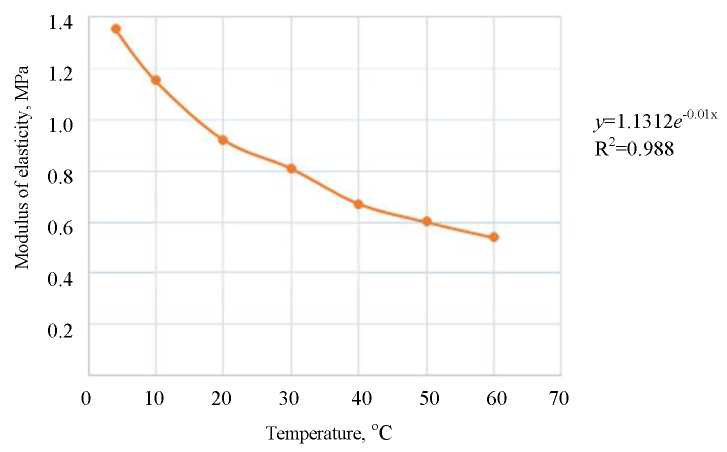

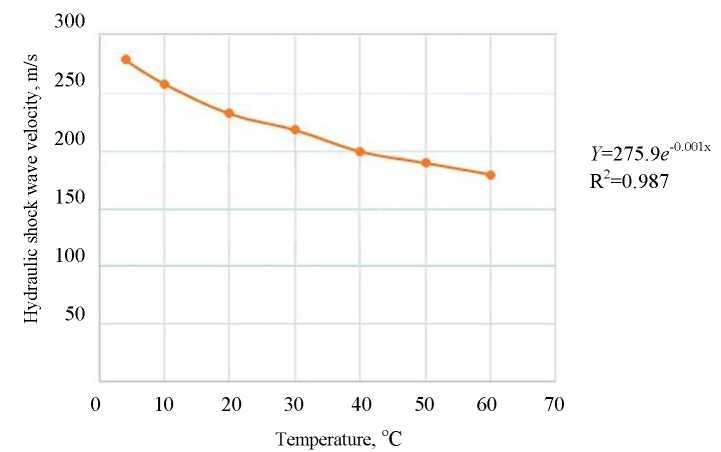

Figure 5 shows a decrease in the value of the elastic modulus of polyethylene with an increase in temperature, and Figure 6 shows a decrease in the value of the hydraulic shock wave propagation velocity with an increase in temperature.

Table 6

Values of elastic modulus of PE 100 polyethylene and hydraulic shock wave propagation velocity at specified temperatures

Fig. 5. Values of the elastic modulus of polyethylene with increasing temperature

Fig. 6. Values of the hydraulic shock wave propagation velocity with increasing temperature

Discussion and Conclusions. After analyzing the results obtained in the course of research, we can draw the following conclusions:

— high water temperature has a significant impact on the properties of the material of pipes made of highdensity polyethylene PE 100 and on the hydraulic properties of the hydraulic shock wave;

— the value of the elastic modulus of high-density polyethylene PE 100 decreases with increasing water temperature, and the value of the decrease at a temperature of 60 °C reaches 60.21% compared to its value at a water temperature of +4 °C. This decrease is relatively large and causes a significant decrease in the values of the hydraulic shock wave propagation velocity, and the magnitude of the decrease reaches 35.71% compared to its value at a water temperature of +4 °C, which leads to a noticeable decrease in the value of the maximum pressure change as a result of water hammer, taking into account the density of water and its elasticity coefficient depending on temperature. When calculating the value of the hydraulic shock wave propagation velocity, the ratings of the maximum pressure change is also taken into account;

— based on the data obtained (shown in Fig. 5), an exponential equation was derived to calculate the value of the polyethylene coefficient as a function of time E=1.312e-0,01t with correlation coefficient R2=0,988;

— according to the data given in Figure 6, an exponential equation was derived to calculate the value of the hydraulic shock wave propagation velocity as a function of time C=275,9e-0,01t. with correlation coefficient R2=0,988.

References

1. Li Chao. The Research Status of the Wetting of Metal/Ceramic in the High Temperature Self-Lubricating Materials / Li Chao, Wang Yan Jun, Qin Ke, et al. // International Journal of Materials Science and Applications. — 2016. — Vol. 5. — P. 108–112. DOI: 10.11648/j.ijmsa.20160502.22

2. Amer Karnoub. Investigation of the impact behavior for composite materials reinforced by glass fibers / Amer Karnoub, Hajian Huang, Imad Antypas // Journal of Physics: Conference Series. Engineering and Innovative Technologies. — 2020. — Vol. 1515 — Art. 042081. DOI: 10.1088/1742-6596/1515/4/042081

3. Antypas, I. R. The influence of polyethylene processing on the plastic containers blowing / I. R. Antypas // Journal of Physics: Conference Series. — 2020. — Vol. 1515. — Art. 042042. https://doi.org/10.1088/1742-6596/1515/4/042042

4. Qingquan Lai. Enhanced wetting of dual-phase metallic solids by liquid metals: A new effect of interfacial reaction / Qingquan Lai, Lei Zhang, N. Eustathopoulos // Acta Materialia. — 2013. — Vol. 61, P. 4127–4134. https://doi.org/10.1016/j.actamat.2013.03.039

5. Buekens, A. Recycling of WEEE plastics: a review / Alfons Buekens, Jie Yang // Journal of material Cycle and Waste Management. — 2014. — Vol. 16. — P. 415–434.

6. Antypas, I. R. Improvement of mechanical behavior of neoprene rubber by means of glass fiber / I.R. Antypas // Journal of Physics: Conference Series. Engineering and Innovative Technologies. — 2021. — Vol. 1889. — Art. 042007.

7. Wuyi Wan. Sensitivity analysis for the resistance on the performance of a pressure vessel for water hammer protection / Wuyi Wan, Wenrui Huang, Cong Li // Journal of Pressure Vessel Technology. — 2014. — Vol. 136. — Art. 011303. https://doi.org/10.1115/1.4025829

8. Yan Gao. Simplified dispersion relationships for fluid-dominated axisymmetric wave motion in buried fluid- filled pipes / Yan Gao, Fusheng Sui, Jennifer M. Muggleton, et al. Journal of Sound and Vibration. — 2016. — Vol. 375. — P. 386–402. https://doi.org/10.1016/j.jsv.2016.04.012

9. Jinzhe Gong. Detecting thinner-walled pipe sections using a spark transient pressure wave generator / Jinzhe Gong, Martin F. Lambert, Si T. N. Nguyen, et al. // Journal of Hydraulic Engineering. — 2018. — Vol. 144. — P. 1–8. DOI: 10.1061/(ASCE)HY.1943-7900.0001409

10. Lars-Eric Janson. Plastics pipes for water supply and sewage disposal / Lars-Eric Janson. — Stockholm: Borealis, 2003. — 404 p.

11. Twyman, J. Wave Speed Calculation For Water Hammer Analysis / John Twyman. — Obras y Proyectos. — 2016. — Vol. 20. — P. 86–92.

12. Espinoza-Moreno, G. Effect of the Temperature in Negative Pressure Wave Methods for Real Time Leak Location Applied to Plastic Water Pipelines / G. Espinoza-Moreno, O. Begovich // Memorias del XVI Congreso Latinoamericano de Control Automático, CLCA. — Mexico: Cancún, Quintana Roo, 2014. — P. 564–569.

13. Chadwick, A. Hydraulics in civil and environmental engineering / Andrew Chadwick, John Morfett, Martin Borthwick. — CRC Press, 2021. — 652 p. DOI: 10.1061/(ASCE)0733-9429(2000)126:9(724)

14. Wei-Li Wu. High density polyethylene film toughened with polypropylene and linear low density polyethylene / Wei-Li Wu, Yi-Wen Wang // Materials Letters. — 2019. — Vol. 257. — Art. 126689. https://doi.org/10.1016/j.matlet.2019.126689

About the Authors

I. R. AntypasRussian Federation

Rostov-on-Don

A. G. Dyachenkо

Russian Federation

Rostov-on-Don

Saed Bakir Imad

Syrian Arab Republic

Aleppo, Syria

Review

For citations:

Antypas I.R., Dyachenkо A.G., Imad S.B. Liquid temperature effect on the hydraulic shock wave velocity in polyethylene pipes. Advanced Engineering Research (Rostov-on-Don). 2021;21(4):319-327. https://doi.org/10.23947/2687-1653-2021-21-4-319-327