Scroll to:

Finite Element Design and Analysis of Sustainable Mono-Reinforced and Hybrid-Reinforced Fibergeopolymers

https://doi.org/10.23947/2687-1653-2025-25-3-171-185

EDN: UKVSSN

Abstract

Introduction. Environmental improvement involves the recycling of man-made materials for product recovery with high performance characteristics. However, in general, energy-intensive and uneconomical materials have no alternative in construction. Literary information on the problem is insufficient and uncompiled. The presented article is intended to fill this gap. The research objective is to study mono-reinforced and hybrid-reinforced fibergeopolymers. For this purpose, two problems are solved: design of polymers and analysis of beams made from them using the finite element method.

Materials and Methods. The binding base for the production of fibergeopolymers was sintered particles (beads) extracted from basalt wool waste — technogenic fibrous materials (TFM). The fiber was made from metal cord, basalt wool waste and polypropylene. Beams made from hybrid-reinforced fibergeopolymers were studied under bending and shear in the ANSYS 16.1 software environment.

Results. Two types of geopolymers were obtained: – mono-reinforced (fiber from metal cord, polypropylene fiber, and TFM – fiber from waste from basalt wool production); – hybrid-fiber-reinforced (metal cord + polypropylene, metal cord + TFM, polypropylene + TFM). High values of elastic modulus (more than 25 GPa), bending strength (up to 10.19 MPa) and compression strength (up to 46.67 MPa) were defined. The ratio of bending and compression strength for the studied and traditional materials was 1:4 and 1:10, respectively. The simulated and experimental indicators of beam deflections under loads from 5 to 72 kN were compared. It was found that finite element modeling allowed designing structures from the developed materials and predicting their performance characteristics.

Discussion. The cases of the smallest discrepancy between the modeling and experimental data were established. For FGP-1, it was 8% (load — 35 kN), for FGP-2 — 11% (50 kN), for FGP-3 — 7% (38 kN), for FGP-1 (1%) — 3% (30 kN). Among the hybrid-reinforced fibergeopolymers, the best compliance was that of HFGP-3. At a load of 55 kN, the discrepancy was 0.80% (theory — 4.98 mm, experiment — 5.02 mm). For HFGP-1, the best indicator was 1.85% (72 kN, 5.85 mm, 5.96 mm), for HFGP-2 — 9.12% (63 kN, 5.58 mm, 6.14 mm). The applied value of the results was confirmed by their visualization – the similarity and coincidence of the curves on the graphs.

Conclusion. The advantages of the proposed innovative components for the production of building materials are proved. They are environmentally friendly and show sufficient workability. Design of hybrid-reinforced fibergeopolymers makes it possible to obtain high values of bending and compression strength (significantly higher than that of unreinforced concrete). The modulus of elasticity of more than 25 GPa proves good resistance of the material to deformations. The results of the modeling are adequate to the results of the experiments.

Keywords

For citations:

Кlyuev S.V., Klyuev A.V., Аyubov N.А., Fediuk R.S., Levkina Е.V. Finite Element Design and Analysis of Sustainable Mono-Reinforced and Hybrid-Reinforced Fibergeopolymers. Advanced Engineering Research (Rostov-on-Don). 2025;25(3):171-185. https://doi.org/10.23947/2687-1653-2025-25-3-171-185. EDN: UKVSSN

Introduction. One of the priorities of the strategy of scientific and technical development of the Russian Federation is to counteract man-made, biogenic, sociocultural and other sources of danger to society and the economy [1]. The most important task of environmental safety is the development of processes and techniques [2], resource conservation [3], and complex processing of man-made materials [4], obtaining products with high performance characteristics on their basis [5].

Transdisciplinary approaches provide a new level of development of building composite mixtures. For progress in this area, it is important to move away from the current templates of designing building materials [6]. To reduce the complexity of recipes and the cost of components, it is necessary to use data from various sciences: materials science, physics, chemistry, geology, nanotechnology, etc. In addition, certain operational characteristics can be assigned to the new composite [7].

Improvement of physical, mechanical, operational, protective and environmental properties of modern modified composites is based on:

- optimization of formulations and technologies;

- use of non-traditional types of natural and man-made raw materials[8].

It is known that the economic efficiency of projects is largely determined by the use of high-tech building materials [9]. Modern composites have good prospects in industrial and civil construction [9]. They are often used for unique projects and objects that are operated under various conditions [10].

When producing the materials described above, one of two innovative strategies is usually used:

- recycling for the production of so-called “green” materials [11];

- creation of “smart” concrete for monitoring the condition of building structures [12].

It should be noted that the regulatory framework governing construction design does not contain recommendations on the use of man-made waste as fillers for concrete. Promising approaches are discussed in the literature. As a rule, this concerns the comprehensive processing of used tires, as well as fibrous materials — man-made waste from the production of mineral wool [13]. However, both of these solutions have not been sufficiently studied and tested in practice.

The possibility of using carbon black and TFM waste should also be mentioned. However, even in this case there are no adequate scientific conclusions that would prove the practical feasibility of introducing such composites into construction practice [14].

The objective of the presented work was to study and design unreinforced and hybrid-reinforced fibergeopolymers using the FEM. Within the framework of this study, two problems were solved: design of hybrid-reinforced fibergeopolymers and analysis of beams made from them by the FEM. This was required to reach the stated goal, as well as in general for the creation of sustainable building materials.

Materials and Methods. The binding base for the production of fibergeopolymers was sintered particles (beads) extracted from waste basalt wool — technogenic fibrous materials (TFM). A combination of sodium silicate and sodium hydroxide solution was used as an alkaline activating liquid. Polyfractionated quartz sand with a specific gravity of 2.67 acted as a fine filler. The maximum size of the coarse aggregate used in this study did not exceed 12 mm, which increased the workability of concrete. The fiber from the metal cord of waste tires was heat-treated and cut. The fiber from TFM was obtained through grinding basalt wool. The authors found that sometimes the actual technical properties of the fibers differed from those declared by the manufacturers, and these actual parameters are given in Table 1.

Table 1

Properties of Different Types of Fiber

|

Properties |

Metal cord |

Polypropylene |

TFM |

|

Diameter, mm |

0.75 |

0.002 |

0.013 |

|

Length, mm |

60–75 |

12.0 |

40–70 |

|

Length to diameter ratio |

80–100 |

6,000 |

3,077–5,385 |

|

Tensile strength, MPa |

2,500 |

3.50 |

2,000 |

|

Modulus of elasticity, MPa |

210 |

3.45 |

75,000 |

|

Specific gravity |

8 |

0.90 |

2.6 |

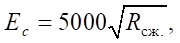

The behavior of 1,000×200×100 mm beams made from hybrid-reinforced fiber-geopolymers was studied. They were analyzed by the FEM in bending and shear. The deflection of geopolymer concrete beams was calculated to prevent unacceptable deformations and provide normal operation of structures. The FEM is suitable for computer processing, it can be used to solve problems in solid mechanics, fluid mechanics, heat transfer and vibrations.

Research Results. Compositions of sustainable fibergeopolymer mixtures have been developed, which show satisfactory workability characteristics (Table 2). Workability provides high-quality, safe transportation of the geopolymer mixture to the place of installation.

Table 2

Developed Compositions and Cone Slump Measurement Results

|

Composition |

Fiber content, % by volume |

Slump, mm |

Workability |

|

Cement concrete |

– |

112.1 |

High |

|

Unreinforced geopolymer (GP) |

– |

103.5 |

High |

|

Fibergeopolymer (FGP-1), metal cord |

0.5 |

80.3 |

Average |

|

FGP-2, polypropylene |

0.5 |

78.4 |

Average |

|

FGP-3, TFM |

0.5 |

76.5 |

Average |

|

Hybrid fibergeopolymer (HFGP-1), metal cord + polypropylene |

0.25 + 0.25 |

65.4 |

Average |

|

HFGP-2, metal cord + TFM |

0.25 + 0.25 |

70.2 |

Average |

|

HFGP-3, TFM + polypropylene |

0.25 + 0.50 |

68.7 |

Average |

The composites were cured for 28 days under normal, unintentionally specified conditions. Their final mechanical properties were summarized in Table 3. High values of compressive strength (up to 46.67 MPa) and bending strength (up to 10.19 MPa) were shown. An extremely important difference in the ratio of bending and compressive strength for the studied and traditional materials was established — 1:4 and 1:10, respectively. High modulus of elasticity (more than 25 GPa) is especially important for designers and engineers, since it determines the ability of the material to resist deformation, i.e., the strength and stability of building structures. In Table 3, the compositions with the best characteristics are highlighted in color.

Table 3

Mechanical Properties of Composite Materials after Curing for 28 Days

|

Composition |

Strength, MPa |

Modulus of elasticity, GPa |

|

|

compressive |

bending |

||

|

Cement concrete |

40.89 |

4.60 |

19.24 |

|

Unreinforced geopolymer (GP) |

41.33 |

4.40 |

19.32 |

|

Fibergeopolymer (FGP-1) |

46.67 |

8.79 |

25.01 |

|

FGP-2 |

45.78 |

8.60 |

24.57 |

|

FGP-3 |

34.67 |

8.00 |

20.02 |

|

Hybrid fibergeopolymer (HFGP-1) |

46.67 |

8.39 |

25.03 |

|

HFGP-2 |

44.44 |

10.19 |

23.49 |

|

HFGP-3 |

40.44 |

9.50 |

20.11 |

The statics problems were solved by the FEM. The sequence of analysis in the Ansys software environment is described below.

- Setting the algorithm.

- Specifying the geometry.

- Specifying and determining the material properties (modulus of elasticity and Poisson's ratio).

For the modeling, a geopolymer beam with three degrees of freedom at each node was used. It moved and was elastically deformed in x, y, z directions.

Modulus of elasticity of concrete:

(1)

(1)

where Ec — short-term static modulus of elasticity, MPa;  — compressive strength, MPa.

— compressive strength, MPa.

Poisson's ratio is usually less than 0.5. In [15], the values from 0.18 to 0.24 are given, while in [16], the figures are from 0.23 to 0.32.

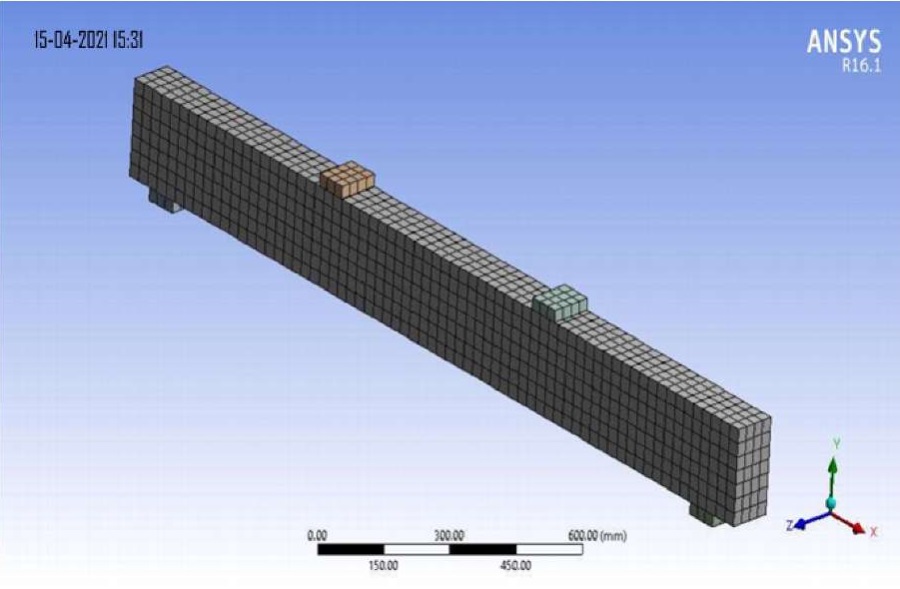

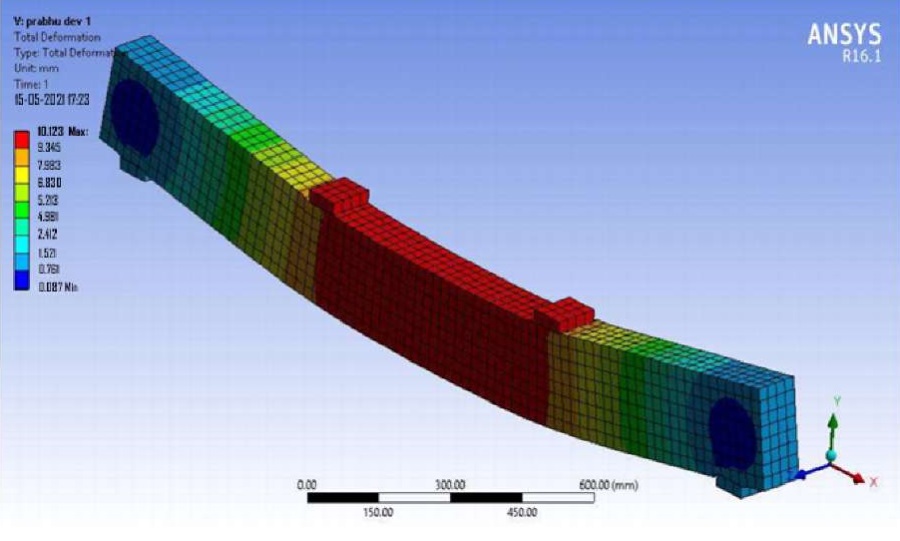

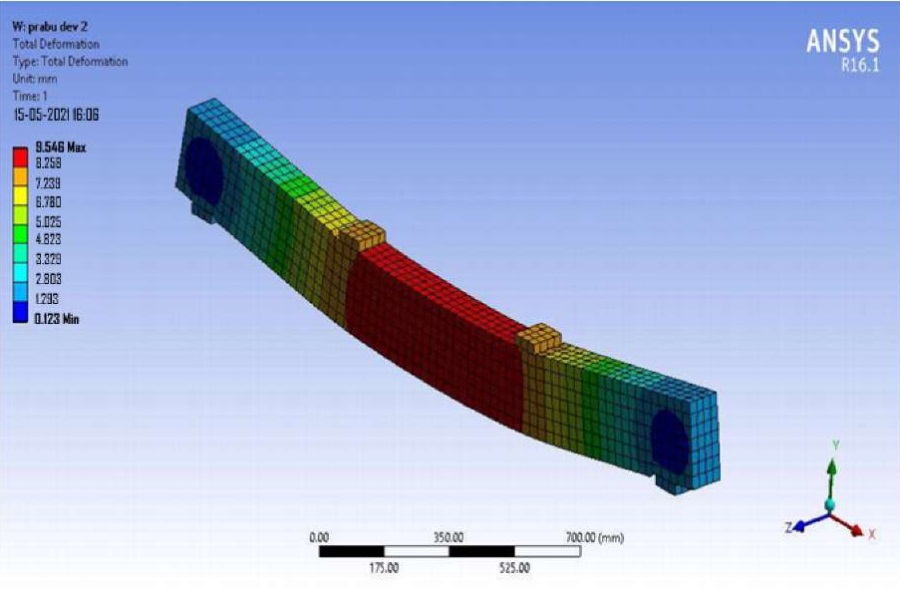

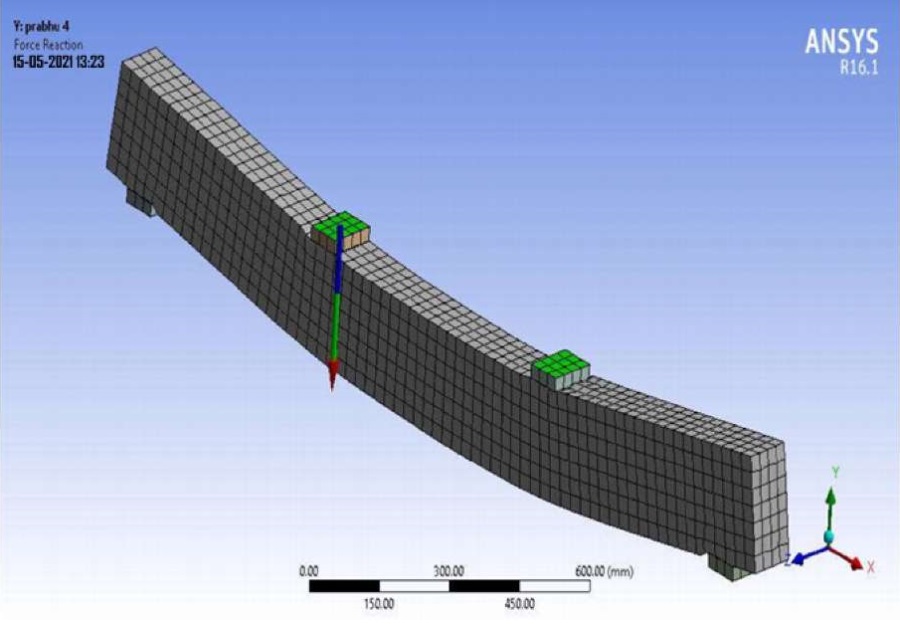

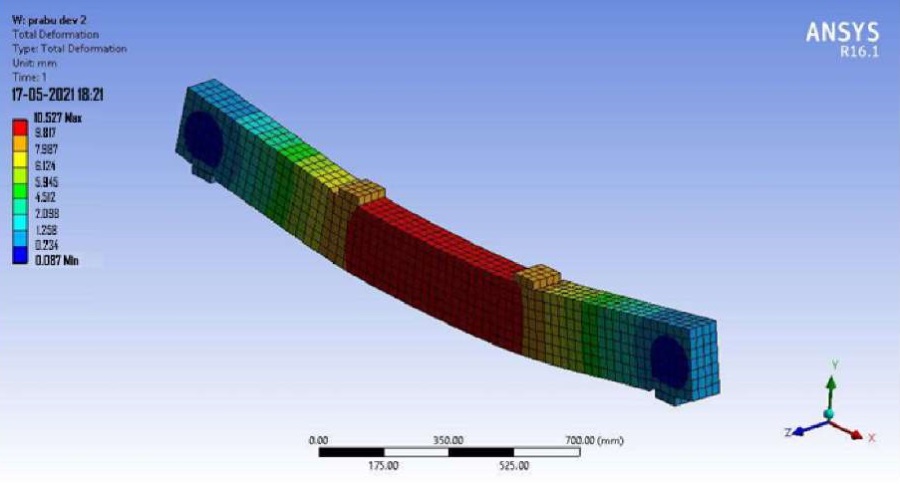

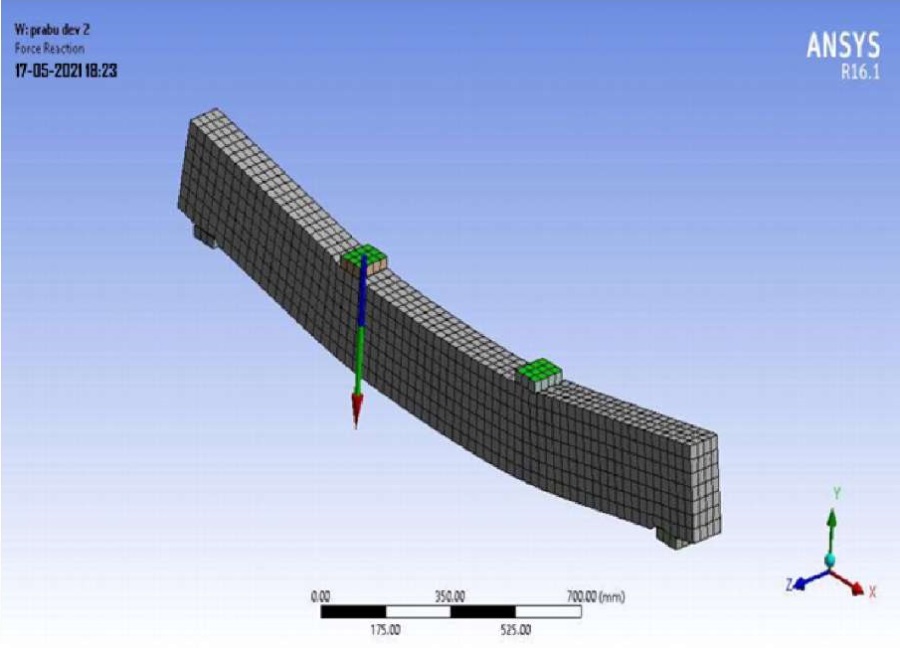

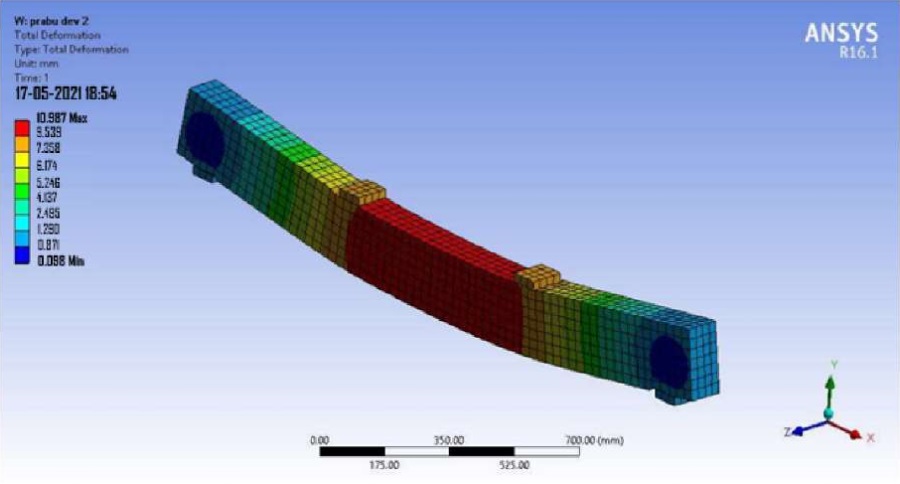

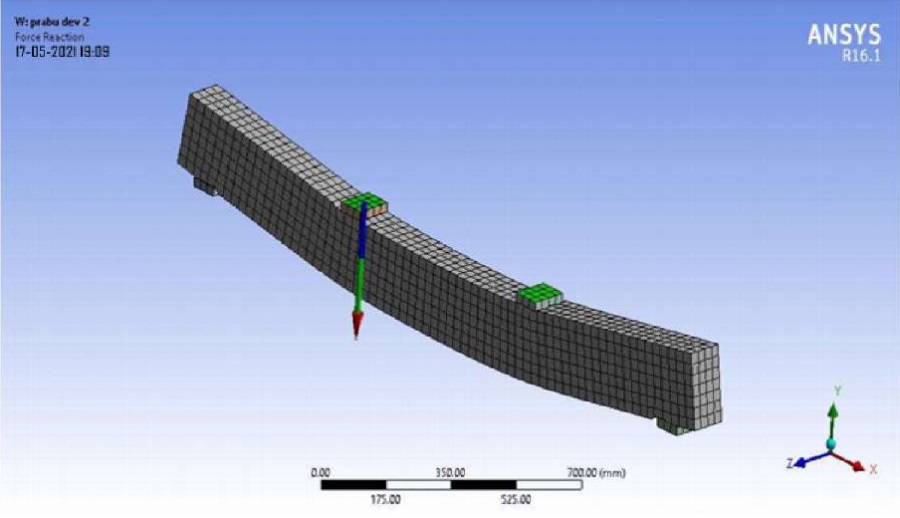

Meshing is based on the geometry of the structure. Visualization of the bending analysis in Ansys is shown in Figures 1–11.

Fig. 1. Beam discretization

Fig. 2. Deformation of beam FGP-1

Fig. 3. Deflection of beam FGP-1

Fig. 4. Deformation of GP beam

Fig. 5. Deflection of GP beam

Fig. 6. Deformation of beam HFGP-1

Fig. 7. Deflection of beam HFGP-1

Fig. 8. Deformation of beam HFGP-2

Fig. 9. Deflection of beam HFGP-2

Fig. 10. Deformation of beam HFGP-3

Fig. 11. Deflection of beam HFGP-3

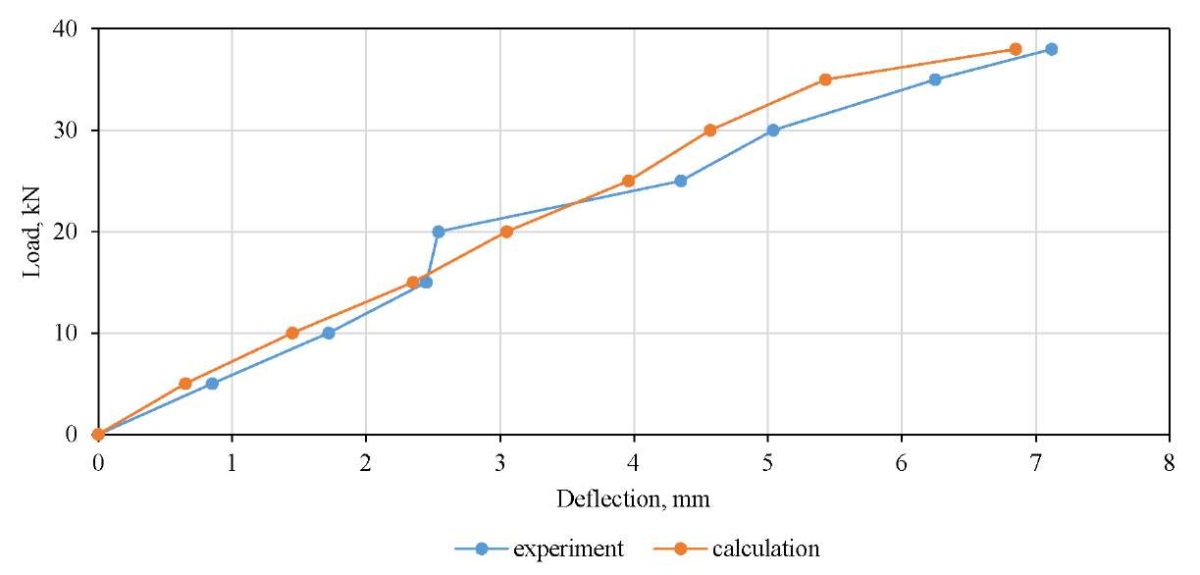

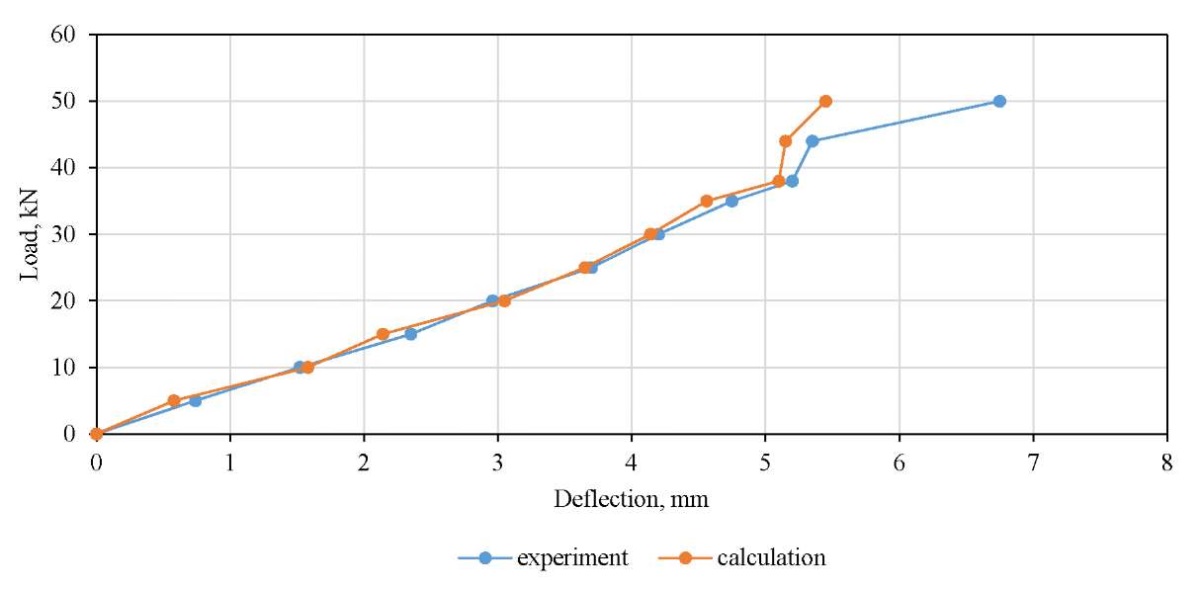

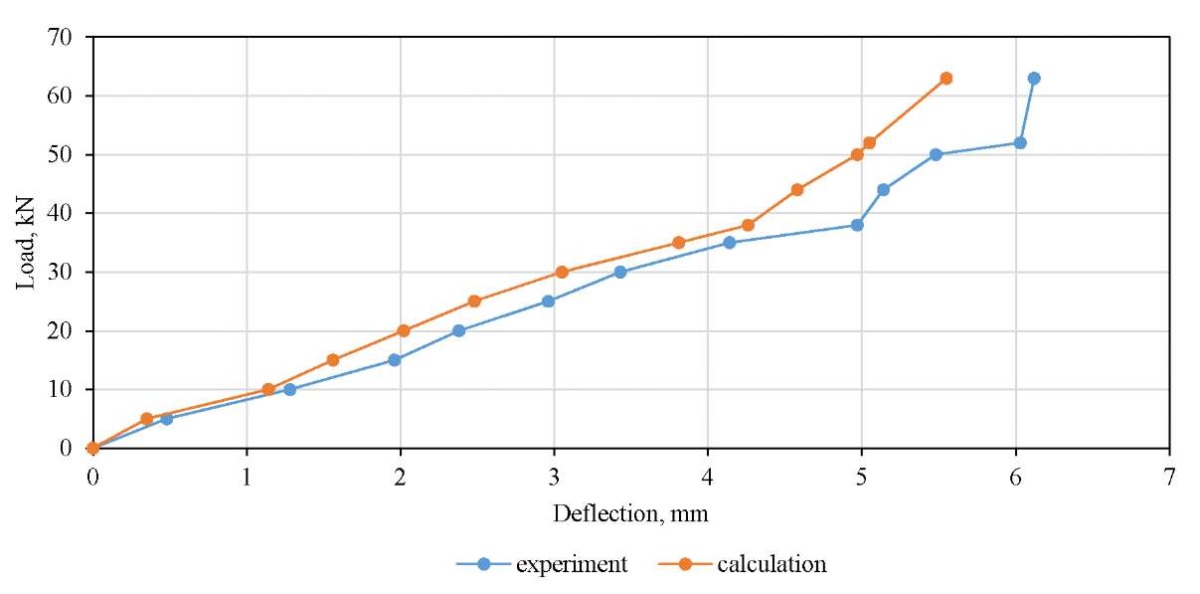

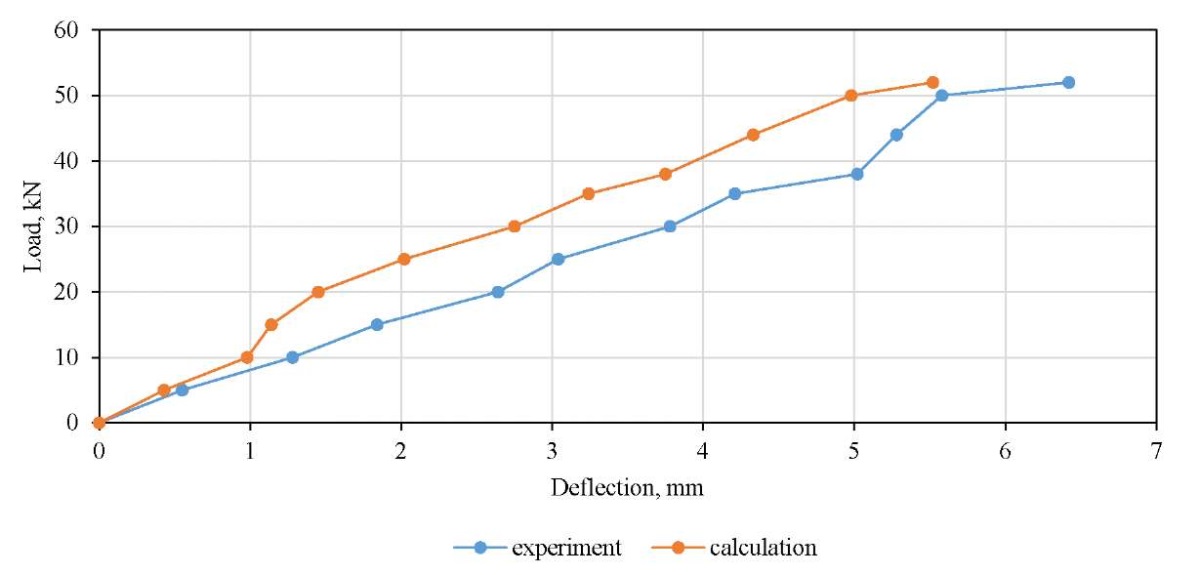

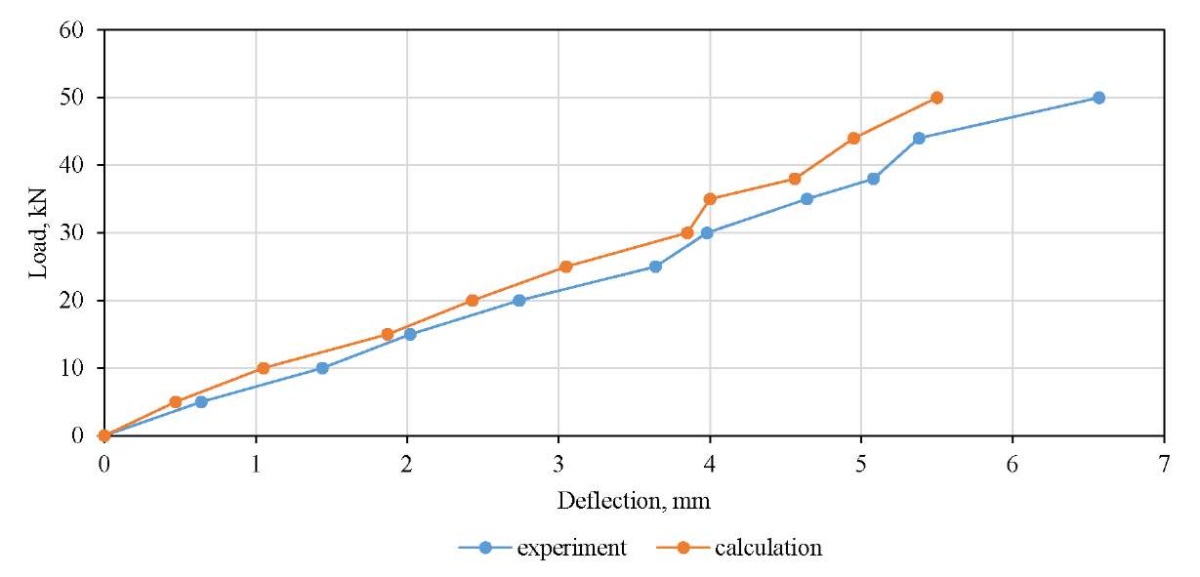

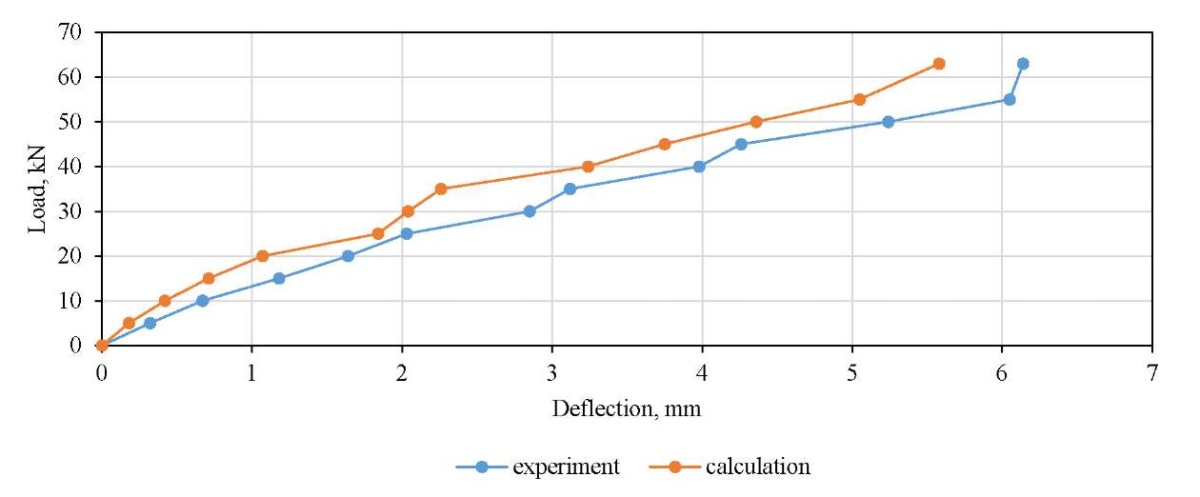

Comparison of the experimental and theoretical results of deflection is given in Tables 4, 5 and Figures 12–17. Geopolymer concrete is an elastic-plastic material, therefore the stress-strain graph is nonlinear.

Table 4

Comparison of Experimental and Theoretical Results of Deflection

|

Load, kN |

Cement concrete |

GP |

FGP-1 |

FGP-2 |

FGP-3 |

FGP-1(1 %) |

||||||||||||

|

Deflection, mm |

Difference, % |

Deflection, mm |

Difference, % |

Deflection, mm |

Difference, % |

Deflection, mm |

Difference, % |

Deflection, mm |

Difference, % |

Deflection, mm |

Difference, % |

|||||||

|

exper. |

calc. |

exper. |

calc. |

exper. |

calc. |

exper. |

calc. |

exper. |

calc. |

exper. |

calc. |

|||||||

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

5 |

0.85 |

0.65 |

24 |

0.74 |

0.58 |

22 |

0.48 |

0.35 |

27 |

0.55 |

0.43 |

22 |

0.70 |

0.42 |

40 |

0.64 |

0.47 |

27 |

|

10 |

1.72 |

1.45 |

16 |

1.52 |

1.58 |

4 |

1.28 |

1.14 |

11 |

1.28 |

0.98 |

23 |

1.56 |

0.95 |

39 |

1.44 |

1.05 |

27 |

|

15 |

2.45 |

2.35 |

4 |

2.35 |

2.14 |

9 |

1.96 |

1.56 |

20 |

1.84 |

1.14 |

38 |

2.18 |

1.47 |

33 |

2.02 |

1.87 |

7 |

|

20 |

2.54 |

3.05 |

20 |

2.96 |

3.05 |

3 |

2.38 |

2.02 |

15 |

2.64 |

1.45 |

45 |

2.89 |

2.04 |

29 |

2.74 |

2.43 |

12 |

|

25 |

4.35 |

3.96 |

9 |

3.70 |

3.65 |

1 |

2.96 |

2.48 |

16 |

3.04 |

2.02 |

34 |

3.34 |

2.90 |

13 |

3.64 |

3.05 |

16 |

|

30 |

5.04 |

4.57 |

9 |

4.20 |

4.14 |

1 |

3.43 |

3.05 |

11 |

3.78 |

2.75 |

27 |

4.10 |

3.47 |

15 |

3.98 |

3.85 |

3 |

|

35 |

6.25 |

5.43 |

13 |

4.75 |

4.56 |

4 |

4.14 |

3.81 |

8 |

4.21 |

3.24 |

23 |

4.98 |

4.25 |

15 |

4.64 |

4.00 |

14 |

|

38 |

7.12 |

6.85 |

4 |

5.20 |

5.10 |

2 |

4.97 |

4.26 |

14 |

5.02 |

3.75 |

25 |

5.47 |

5.07 |

7 |

5.08 |

4.56 |

10 |

|

44 |

– |

– |

– |

5.35 |

5.15 |

4 |

5.14 |

4.58 |

11 |

5.28 |

4.33 |

18 |

6.76 |

5.48 |

19 |

5.38 |

4.95 |

8 |

|

50 |

– |

– |

– |

6.75 |

5.45 |

19 |

5.48 |

4.97 |

9 |

5.58 |

4.98 |

11 |

– |

– |

– |

6.57 |

5.50 |

16 |

|

52 |

– |

– |

– |

– |

– |

– |

6.03 |

5.05 |

16 |

6.42 |

5.52 |

14 |

– |

– |

– |

– |

– |

– |

|

63 |

– |

– |

– |

– |

– |

– |

6.12 |

5.55 |

9 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

Fig. 12. Deflection of a cement concrete beam

Fig. 13. Deflection of GP beam

Fig. 14. Deflection of beam FGP-1

Fig. 15. Deflection of beam FGP-2

Fig. 16. Deflection of beam FGP-3

Fig. 17. Deflection of beam FGP-1 with 1% of metal cord fiber

Table 5

Comparison of Experimental and Theoretical Deflection Results for Hybrid-Reinforced Fibergeopolymers

|

Load, kN |

Deflection, mm |

|||||

|

HFGP-1 |

HFGP-2 |

HFGP-3 |

||||

|

exper. |

calc. |

exper. |

calc. |

exper. |

calc. |

|

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

5 |

0.26 |

0.14 |

0.32 |

0.18 |

0.30 |

0.17 |

|

10 |

0.55 |

0.37 |

0.67 |

0.42 |

0.58 |

0.37 |

|

15 |

0.97 |

0.64 |

1.18 |

0.71 |

1.05 |

0.82 |

|

20 |

1.28 |

0.99 |

1.64 |

1.07 |

1.54 |

1.02 |

|

25 |

1.86 |

1.14 |

2.03 |

1.84 |

2.07 |

1.71 |

|

30 |

2.04 |

1.86 |

2.85 |

2.04 |

2.48 |

2.10 |

|

35 |

2.74 |

2.41 |

3.12 |

2.26 |

3.99 |

2.89 |

|

40 |

3.04 |

2.74 |

3.98 |

3.24 |

4.29 |

3.12 |

|

45 |

3.65 |

3.24 |

4.26 |

3.75 |

4.54 |

3.92 |

|

50 |

3.98 |

3.74 |

5.24 |

4.36 |

4.96 |

4.26 |

|

55 |

4.18 |

4.08 |

6.05 |

5.05 |

5.02 |

4.98 |

|

63 |

4.86 |

4.66 |

6.14 |

5.58 |

5.64 |

5.21 |

|

64 |

5.26 |

4.89 |

– |

– |

6.03 |

5.74 |

|

70 |

5.77 |

5.14 |

– |

– |

– |

– |

|

72 |

5.96 |

5.85 |

– |

– |

– |

– |

Fig. 18. Deflection of beam HFGP-1

Fig. 19. Deflection of beam HFGP-2

Fig. 20. Deflection of beam HFGP-3

Thus, the finite element modeling of beams made from mono-reinforced and hybrid-reinforced fibergeopolymers has shown good convergence of experimental and theoretical results, which allows for the efficient design of structures from the developed materials and the prediction of their operational characteristics.

Discussion. The most noticeable discrepancy between the results of experiments and calculations (45%) was found for FGP-2 at a load of 20 kN. At 15 kN, the difference was 38%. However, in this and the following cases, it is important to emphasize the low absolute values. At 20 kN, a deflection of 1.45 mm was theoretically assumed, but the experiment showed 2.64 mm. The corresponding data at 15 kN were 1.14 and 1.84. At other loads, the difference was significantly smaller. For FGP-3, the maximum discrepancy was recorded at minimum loads: 40% at 5 kN and 39% at 10 kN. If we are talking about absolute figures, then in the first case, the calculation is 0.42 mm, the experiment is 0.70 mm. In the second case, 0.95 mm and 1.56 mm, respectively. For FGP-1 and FGP–1 (1%), the maximum discrepancy did not exceed 27%, and at low loads. At loads of 5 kN, the theoretically obtained deflection indicator for FGP-1 is 0.35 mm, established empirically — 0.48 mm. The difference is 27%. At a load of 5 kN for FGP-1 (1%), the calculation shows a deflection of 0.47 mm, the experiment — 0.64 mm. The corresponding data for 10 kN are 1.05 and 1.44. The difference in both cases is 27%. For other loads, it is significantly less.

Let us also note the cases of the best convergence of the calculation and experimental data. For FGP-1, this is 8% (load — 35 kN), for FGP-2 — 11% (50 kN), for FGP-3 — 7% (38 kN), for FGP-1 (1%) — 3% (30 kN).

The results of the study of hybrid-reinforced fibergeopolymers allow us to state that the most significant discrepancy between theory and experiments is recorded at minimum loads (in this case, 5 kN). Thus, for HFGP-1, it is 46.2% (calculation shows a deflection of 0.14 mm, experiment — 0.26 mm). The corresponding difference for HFGP-2 is 43.8% (0.18 mm and 0.32 mm), for HFGP-3 — 43.3% (0.17 and 0.30). At other loads, the discrepancies are smaller.

The best agreement between calculations and experimental results for HFGP-1 is 1.85%. This figure is recorded at a load of 72 kN (theory — 5.85 mm, experiment — 5.96 mm). The smallest discrepancy, obtained when modeling the deflection for HFGP-2, is 9.12% (63 kN, 5.58 mm and 6.14 mm, respectively). For HFGP-3 — 0.80% (55 kN, 4.98 mm and 5.02 mm). As noted above, extremely minor discrepancies in absolute figures should be taken into account. Both individual and generalized data are of interest for design and engineering practice. This is confirmed by the visualization of the results of the work — the curves in Figures 12-20 are similar or coincide in numerous cases.

Conclusion. Innovative components for the production of sustainable building materials have been obtained [17]. Ecological compatibility is due to the fact that an alternative to cement is used [18], and this provides a significant reduction in greenhouse gas emissions. The design of hybrid-reinforced fibergeopolymers makes it possible to obtain high strength values — both in compression (from 46 MPa) and in bending (from 10 MPa). When using hybrid fiber, it is possible to reach bending and compression strength at the level of 1:4, and this is several times higher than for unreinforced Portland cement concrete [19]. The modulus of elasticity of more than 25 GPa shows good resistance of the material to deformations, which has a positive effect on the strength and stability of building structures [20]. The finite element analysis of hybrid-reinforced fibergeopolymer beams confirmed the experimental results obtained [21].

The three main research results are described below.

- Two types of geopolymers were obtained:

- mono-reinforced (fiber from metal cord, polypropylene fiber, and fiber from waste from basalt wool production — TFM);

- hybrid fiber-reinforced (metal cord+polypropylene, metal cord+TFM, polypropylene+TFM).

- Fiber-reinforced geopolymer concrete mixtures have standard workability characteristics that allow them to be efficiently transported to the place of use and placed in formwork.

- Finite component modeling of beams made from mono-reinforced and hybrid-reinforced fibergeopolymers show good agreement between experimental and theoretical results, which allows for efficient design of structures made from the developed materials and prediction of their performance characteristics [22].

References

1. Laihao Yu, Yingyi Zhang, Zhenghao Zhang, Jialong Yang. Conversion of Recycled Sludge Waste into High Value-Added Ceramics as Engineering Construction Materials: Fabrication, Characterization and Performance Evaluation. Chemical Engineering Journal. 2023;475:146509. https://doi.org/10.1016/j.cej.2023.146509

2. Klyuev AV, Kashapov NF, Klyuev SV, Zolotareva SV, Shchekina NA, Shorstova ES, et al. Experimental Studies of the Processes of Structure Formation of Composite Mixtures with Technogenic Mechanoactivated Silica Component. Construction Materials and Products. 2023:6(2):5–18. https://doi.org/10.58224/2618-7183-2023-6-2-5-18

3. Fediuk R, Amran M, Klyuev S, Klyuev A. Increasing the Performance of a Fiber-Reinforced Concrete for Protective Facilities. Fibers. 2021;9(11):64. https://doi.org/10.3390/fib9110064

4. Bespolitov DV, Konovalova NA, Pankov PP, Shavanov ND. Overburden Recycling in Manufacture of Composite Materials for Road Construction at Mines. Journal of Mining Science. 2023;59(1):167–175. https://doi.org/10.1134/S1062739123010180

5. Klyuev S, Klyuev A, Fediuk R, Ageeva M, Fomina E, Amran M, et al. Fresh and Mechanical Properties of Low-Cement Mortars for 3D Printing. Construction and Building Materials. 2022;338:127644. https://doi.org/10.1016/j.conbuildmat.2022.127644

6. Volokitina I, Kolesnikov A, Fediuk R, Klyuev S, Sabitov L, Volokitin A, et al. Study of the Properties of Antifriction Rings under Severe Plastic Deformation. Materials. 2022;15(7):2584. https://doi.org/10.3390/ma15072584

7. Gilbert Sebastiano Gondokusumo, Akshay Venkateshwaran, Kiang Hwee Tan, GY Richard Liew. Shear Strength and Ductility of Novel Steel Fibre-Reinforced Concrete Dowel Connections for Composite Beams. Construction and Building Materials. 2024;447:138159. https://doi.org/10.1016/j.conbuildmat.2024.138159

8. Wenjie Ge, Feng Zhang, Yi Wang, Ashraf Ashour, Laiyong Luo, Linfeng Qiu, et al. Machine Learning Predictions for Bending Capacity of ECC-Concrete Composite Beams Hybrid Reinforced with Steel and FRP Bars. Case Studies in Construction Materials. 2024;21:e03670. https://doi.org/10.1016/j.cscm.2024.e03670

9. Klyuev AV, Kashapov NF, Klyuev SV, Lesovik RV, Ageeva MS, Fomina EV, et al. Development of Alkali-Activated Binders Based on Technogenic Fibrous Materials. Construction Materials and Products. 2023:6(1):60–73. https://doi.org/10.58224/2618-7183-2023-6-1-60-73

10. Qi Chen, Xiaoyong Luo, Wangcheng Luo, Zheng Yang, Dan Yang, Xutong Zheng, et al. Seismic Performance of Innovative Precast Concrete Composite Walls with Embedded XPS Insulation Layer. Engineering Structures. 2024;316:118605. https://doi.org/10.1016/j.engstruct.2024.118605

11. Novoselov OG, Sabitov LS, Sibgatullin KE, Sibgatullin ES, Klyuev AS, Klyuev SV, et al. Method for Calculating the Strength of Massive Structural Elements in the General Case of Their Stress-Strain State (Kinematic Method). Construction Materials and Products. 2023;6(3):5–17. https://doi.org/10.58224/2618-7183-2023-6-3-5-17

12. Novoselov OG, Sabitov LS, Sibgatullin KE, Sibgatullin ES, Klyuev AS, Klyuev SV, et al. Method for Calculating the Strength of Massive Structural Elements in the General Case of Their Stress-Strain State (Parametric Equations of the Strength Surface). Construction Materials and Products. 2023;6(2):104–120. https://doi.org/10.58224/2618-7183-2023-6-2-104-120

13. Edlaine Feital Barbosa Motta, Aldo Ribeiro de Carvalho, Júlia Gargiulo Duarte Barra, Indhira-Oliveira Maciel, Thaís Mayra de Oliveira. Thermomechanical Behavior of Concretes with Addition of Non-Functionalized and Functionalized Carbon Nanotubes. Journal of Building Engineering. 2024;96:110642. https://doi.org/10.1016/j.jobe.2024.110642

14. Yuqiang Lin, Wenyong Zheng, Shuhua Liu, Min Yuan, Xi Qin. Multi-Ion Erosion Test and Molecular Dynamics Simulation of Carbon Nanotube Concrete under Stray Current and Salt Brine Environment. Developments in the Built Environment. 2024;17:100335. https://doi.org/10.1016/j.dibe.2024.100335

15. Ige Samuel Ayeni, Nor Hasanah Abdul Shukor Lim, Mostafa Samad. Engineering Properties of Natural FibreReinforced One-Part Geopolymer Concrete. Construction and Building Materials. 2024;456:139161. https://doi.org/10.1016/j.conbuildmat.2024.139161

16. Sarici T, Ozcan M. Using Geopolymer Coated and Uncoated Geotextile as a Hybrid Method to Improve Uplift Capacity of Screw Piles in Cohesionless Soil. Alexandria Engineering Journal. 2024;105:666–681. https://doi.org/10.1016/j.aej.2024.08.042

17. Kachurin NM, Stas GV, Prokhorov DO, Gavrina OA. Selection of Technologies and Directions for Reducing the Technogenic Impact of Mineral Formations on the Environment. Sustainable Development of Mountain Territories. 2024;16(1):283–291. https://doi.org/10.21177/1998-4502-2024-16-1-283-291

18. Zaalishvili VB, Kambolov DA, Melkov DA, Fidarova MI. Statistical Characteristics Calculation of Seismic Intensity Increments for the Purpose of Seismic Microzoning in Mountain Territories. Sustainable Development of Mountain Territories. 2024;16(1):345–357. https://doi.org/10.21177/1998-4502-2024-16-1-345-357

19. Kachurin NM, Prokhorov DO, Stas GV, Gavrina OA. Justification of Technology for Anthropogenic Deposits Development. Sustainable Development of Mountain Territories. 2024;16(3):833–841. https://doi.org/10.21177/1998-4502-2024-16-3-833-841

20. Tyulyaeva Yu, Khayrutdinov A, Galachieva I, Totrukova I. Creation of a High-Strength Backfill Composite Based on Sulfide-Bearing Technogenic Waste from Mining Production. Sustainable Development of Mountain Territories. 2024;16(3):1384–1396. https://doi.org/10.21177/1998-4502-2024-16-3-1384-1396

21. Yazyev SB, Chepurnenko AS. Buckling of Rectangular Plates under Nonlinear Creep. Advanced Engineering Research (Rostov-on-Don). 2023;23(3):257–268. https://doi.org/10.23947/2687-1653-2023-23-3-257-268

22. Kondratieva TN, Chepurnenko AS. Prediction of Rheological Parameters of Polymers by Machine Learning Methods. Advanced Engineering Research (Rostov-on-Don). 2024;24(1):36–47. https://doi.org/10.23947/2687-1653-2024-24-1-36-47.

About the Authors

S. V. КlyuevRussian Federation

Sergey V. Кlyuev, Dr.Sci. (Engineering), Professor, Leading Researcher of the Scientific Research Laboratory of Resource and Energy-Saving Technologies, Equipment and Complexes

46, Kostyukov Str., Belgorod, 308012

ScopusID: 57212454175

A. V. Klyuev

Russian Federation

Alexander V. Кlyuev, Cand.Sci. (Engineering), Associate Professor, Senior Researcher of the Scientific Research Laboratory of Resource and Energy-Saving Technologies, Equipment and Complexes

46, Kostyukov Str., Belgorod, 308012

ScopusID: 56567996100

N. А. Аyubov

Russian Federation

Narman А. Аyubov, Cand.Sci. (Economics), Senior Researcher

21a, Staropromyslovskoe shosse, Grozny, 364906

R. S. Fediuk

Russian Federation

Roman S. Fediuk, Dr.Sci. (Engineering), Professor of the Military Training Center

10, Ajax Bay, Russky Island, Vladivostok, 690922

ScopusID 56512156400

ResearcherID N-6730-2017

Е. V. Levkina

Russian Federation

Еlena V. Levkina, Cand.Sci. (Economics), Associated Professor, Head of the Department for Work with Dissertation Councils

10, Ajax Bay, Russky Island, Vladivostok, 690922

ScopusID 57200571457

Eco-friendly fiber-reinforced geopolymer composites with a high elastic modulus are developed. Mono-reinforced and hybrid-reinforced geopolymers for building components are obtained. Sufficient workability of the mixtures is demonstrated for practical use on construction sites. Experimental compressive and flexural strength properties are validated by measurements. The finite element method effectively predicts beam deflections made from the new composites. The results are applicable in industrial and civil engineering for cost-effective and environmentally friendly structures.

Review

For citations:

Кlyuev S.V., Klyuev A.V., Аyubov N.А., Fediuk R.S., Levkina Е.V. Finite Element Design and Analysis of Sustainable Mono-Reinforced and Hybrid-Reinforced Fibergeopolymers. Advanced Engineering Research (Rostov-on-Don). 2025;25(3):171-185. https://doi.org/10.23947/2687-1653-2025-25-3-171-185. EDN: UKVSSN

JATS XML