MECHANICS

Eco-friendly fiber-reinforced geopolymer composites with a high elastic modulus are developed. Mono-reinforced and hybrid-reinforced geopolymers for building components are obtained. Sufficient workability of the mixtures is demonstrated for practical use on construction sites. Experimental compressive and flexural strength properties are validated by measurements. The finite element method effectively predicts beam deflections made from the new composites. The results are applicable in industrial and civil engineering for cost-effective and environmentally friendly structures.

Introduction. Environmental improvement involves the recycling of man-made materials for product recovery with high performance characteristics. However, in general, energy-intensive and uneconomical materials have no alternative in construction. Literary information on the problem is insufficient and uncompiled. The presented article is intended to fill this gap. The research objective is to study mono-reinforced and hybrid-reinforced fibergeopolymers. For this purpose, two problems are solved: design of polymers and analysis of beams made from them using the finite element method.

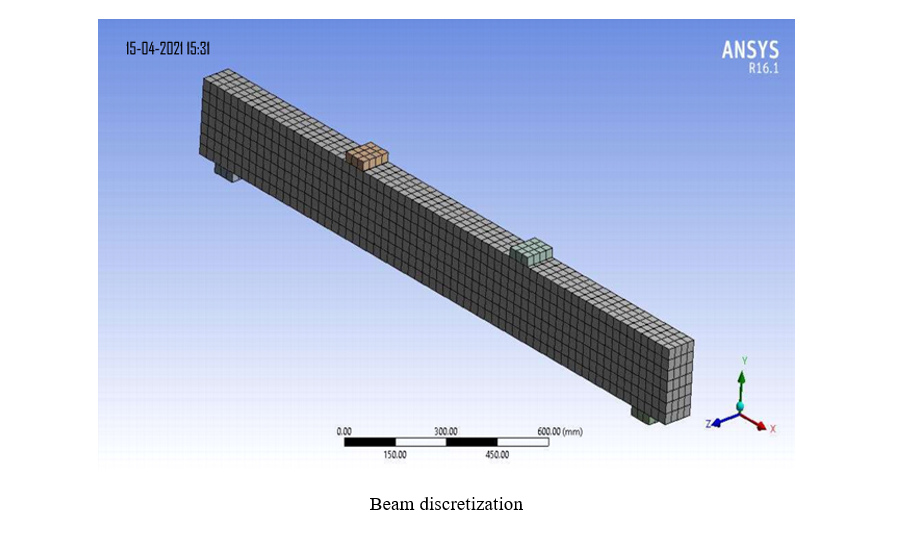

Materials and Methods. The binding base for the production of fibergeopolymers was sintered particles (beads) extracted from basalt wool waste — technogenic fibrous materials (TFM). The fiber was made from metal cord, basalt wool waste and polypropylene. Beams made from hybrid-reinforced fibergeopolymers were studied under bending and shear in the ANSYS 16.1 software environment.

Results. Two types of geopolymers were obtained: – mono-reinforced (fiber from metal cord, polypropylene fiber, and TFM – fiber from waste from basalt wool production); – hybrid-fiber-reinforced (metal cord + polypropylene, metal cord + TFM, polypropylene + TFM). High values of elastic modulus (more than 25 GPa), bending strength (up to 10.19 MPa) and compression strength (up to 46.67 MPa) were defined. The ratio of bending and compression strength for the studied and traditional materials was 1:4 and 1:10, respectively. The simulated and experimental indicators of beam deflections under loads from 5 to 72 kN were compared. It was found that finite element modeling allowed designing structures from the developed materials and predicting their performance characteristics.

Discussion. The cases of the smallest discrepancy between the modeling and experimental data were established. For FGP-1, it was 8% (load — 35 kN), for FGP-2 — 11% (50 kN), for FGP-3 — 7% (38 kN), for FGP-1 (1%) — 3% (30 kN). Among the hybrid-reinforced fibergeopolymers, the best compliance was that of HFGP-3. At a load of 55 kN, the discrepancy was 0.80% (theory — 4.98 mm, experiment — 5.02 mm). For HFGP-1, the best indicator was 1.85% (72 kN, 5.85 mm, 5.96 mm), for HFGP-2 — 9.12% (63 kN, 5.58 mm, 6.14 mm). The applied value of the results was confirmed by their visualization – the similarity and coincidence of the curves on the graphs.

Conclusion. The advantages of the proposed innovative components for the production of building materials are proved. They are environmentally friendly and show sufficient workability. Design of hybrid-reinforced fibergeopolymers makes it possible to obtain high values of bending and compression strength (significantly higher than that of unreinforced concrete). The modulus of elasticity of more than 25 GPa proves good resistance of the material to deformations. The results of the modeling are adequate to the results of the experiments.

A method for optimal control of a lower-limb exoskeleton with elastic elements in the feet is developed. It minimizes energy consumption while accounting for external disturbances and measurement noise. The method is based on the Lagrange model and control synthesis through solving the Riccati equation. It is shown that increasing the stabilization time significantly reduces energy consumption. An analysis of the effect of the stiffness and damping of the elastic elements has revealed a tradeoff between stabilization speed and overshoot. The use of a Kalman filter ensures robust state estimation and stable convergence in the presence of white noise.

Introduction. Modern development of exoskeletons opens new horizons for rehabilitation and improving the quality of life of people with limited mobility. The relevance of the study on methods of optimal control of exoskeletons is due to the growing demand in medicine and industry. However, there are numerous challenges related to the efficient control of exoskeletons, especially in the context of the integration of elastic elements. Topics related to optimal control and tuning of system parameters to reach maximum efficiency and user comfort remain insufficiently studied. The objective of this study is to develop a method of optimal control of a lower limb exoskeleton (LLE) with elastic elements while optimizing energy costs and accounting for external disturbances.

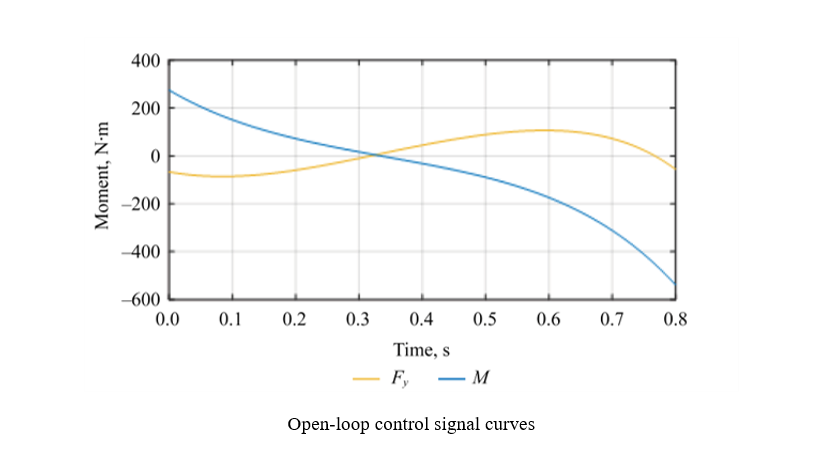

Materials and Methods. The LLE is represented by a simplified model of an inverted pendulum with elastic elements in the feet. The dynamic model of the LLE was developed using Lagrange equations. The optimal control method was based on the synthesis of a linear quadratic regulator designed to minimize energy costs. To account for the influence of external disturbances, a Kalman filter was integrated into the control loop. The parameters of the mathematical model of the LLE were obtained from published data. System simulation was performed in the Wolfram Mathematica environment.

Results. A method of optimal control of the LLE with elastic elements has been developed. This method optimizes energy costs while maintaining vertical equilibrium. The system was modeled using optimal terminal control, followed by optimal feedback control. During feedback control, key parameters affecting system stability were identified: spring stiffness and damping coefficients. Integration of the Kalman filter enabled compensation for external disturbances.

Discussion. The use of terminal control within the developed method reduced energy costs by 98% within a specified stabilization timeframe. Optimal values of spring stiffness and damping coefficients for obtaining the best system response were identified. The use of the optimal control method of the LLE in combination with the Kalman filter confirmed the effective compensation of external disturbances and noise, which provided the convergence of transient processes with minimal energy consumption.

Conclusion. The proposed method for achieving optimal control while minimizing energy costs is a promising solution in the field of control signal calculation required to ensure stability and determine the optimal energy cost function. This is especially true for medical rehabilitation tasks. These results may be useful for further research and development in the field of robotics and wearable devices.

MACHINE BUILDING AND MACHINE SCIENCE

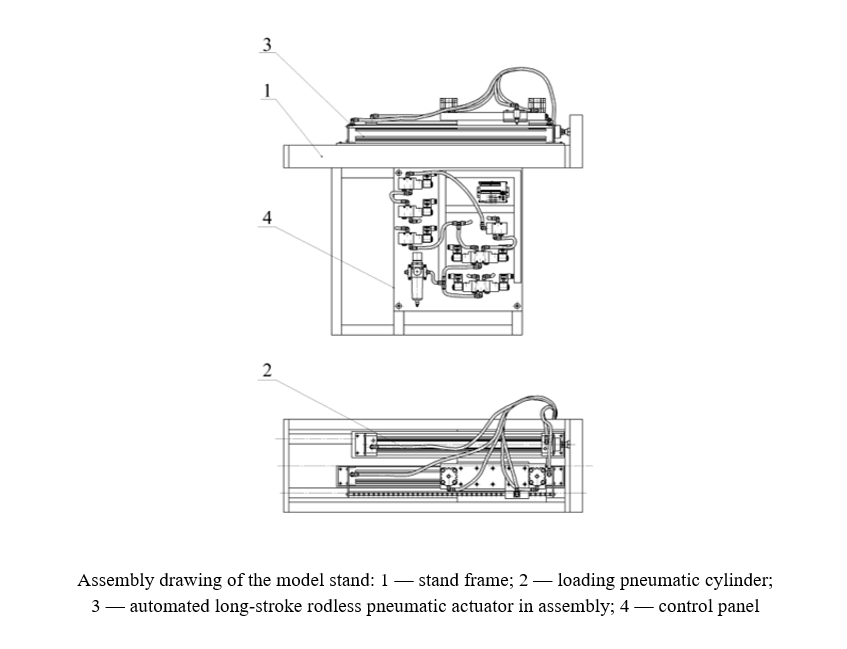

The article experimentally validates a long-stroke rodless pneumatic actuator model with a maximum error of 18%. Full-scale tests were conducted using a unique control system based on a jet sensor and an external brake. It was shown that increasing the mass from 10 to 60 kg reduces positioning accuracy by 40%. A strong impact of the stop coordinate on accuracy was found due to backpressure in the drain cavity. The resulting solutions provided an accuracy of 77 µm over a distance of over three meters with a cost-effective control scheme.

Introduction. In modern industrial processes, pneumatic actuators with long-stroke movements play an important role. However, their use is limited by low accuracy resulting from the difficulties of controlling air flows. These limitations are caused by the compressibility of air and thermodynamic processes, which makes it urgent to improve the accuracy of such systems. The conducted analysis of scientific literature shows that modern research is mainly focused on the use of systems with standard cylinders with a working stroke limited to three meters. At the same time, the issues of development and research of long-stroke systems of rodless pneumatic drives, capable of having a stroke length of up to six meters, remain insufficiently studied. The introduction of advanced control systems in this type of drives involves significant investments in a high-tech electronic base and additional structural elements. In this regard, the development of fundamentally new technical solutions that allow for the efficient operation of mechanisms with a working stroke of more than three meters while maintaining the required technical parameters and economic efficiency, is of particular relevance. In the framework of previous studies, the author proposed a design of a pneumatic drive for long-stroke movements, equipped with a unique control system based on a jet sensor and an external brake mechanism. Its mathematical modeling and theoretical analysis were also performed, which made it possible to identify key factors affecting the accuracy of positioning. To validate the mathematical model and the hypotheses put forward, the objective of this research is to experimentally verify the results of mathematical modeling of a positioning long-stroke rodless pneumatic actuator, as well as to confirm the degree of influence of key factors on positioning accuracy.

Materials and Methods. The work involved a stand that was a technical model of a pneumatic drive with an original control system, including a jet sensor and an external brake device. To verify the operability and accuracy of the jet sensor readings, the spillage method was applied using the Camozzi MF4008-10-R-BV-A flow sensor after the element under study, and Camozzi SWCN-P10-P3-2 pressure sensors placed before and after the considered element. The tests conducted on the developed jet sensor showed high reliability and stability of operation in various operating modes. The experimental study of a long-stroke rodless pneumatic actuator included evaluation of the actuator's technical capabilities, analysis of positional cycles, study on the effect of external factors, and comparison of the results of computational and full-scale experiments. The results of computational and full-scale experiments were processed using the Mathcad and MATLAB software packages. The dependences of positioning accuracy on mass and stroke length were constructed.

Results. The reliability of the model was established at the level of the maximum discrepancy between the experimental data and the results of mathematical modeling, which amounted to 18%. That confirmed the adequacy of the developed model for engineering calculations. The effect of the load mass on the accuracy of positioning was experimentally established. With an increase in mass from 10 to 30 kg, the accuracy decreased by 1.47 times, and with a mass of 60 kg, the accuracy deteriorated by another 1.37 times relative to the base mass of 10 kg. In addition, the effect of stop coordinates was studied: the dependence of positioning accuracy on the position of the actuator was established. When moving from 0.1 m to 0.22 m, the accuracy deteriorated by 3.2 times, but with further movement to 0.35 m, it improved by 2.2 times.

Discussion. The conducted experimental studies allowed achieving good results in the development of long-stroke pneumatic drives. Successful verification of the mathematical model confirmed the correctness of both the model itself and the theoretical studies conducted in the author's previous works. The positioning accuracy of the drive of 77 microns at a distance of over three meters was reached. This indicator significantly exceeds the results presented in the studies of other authors, which shows the high potential of the developed design. The economic efficiency of the proposed solution is due to the absence of an electronic component base in the control system. This not only reduces initial production costs, but also significantly simplifies maintenance of the drive under operation. The comparative analysis with existing developments confirms the superiority of the proposed system in terms of cost criteria.

Conclusion. The conducted studies confirmed the efficiency of the developed solutions for a long-stroke rodless pneumatic actuator. Practical significance of the study is determined by the possibility of using the obtained results in creating high-precision long-stroke mechanisms in various industries. The developed design can be used in automated production lines, robotic complexes, and other areas where precise positioning over significant distances is required. Promising areas for further research are the optimization of the control system parameters to reach even higher positioning accuracy, and the development of calculation methods for positioning long-stroke pneumatic drives.

An experimental approach is developed to assess the effect of electrode spacing on the shape and geometry of the deposited layer using a twin-arc. It is shown that increasing the spacing between electrodes widens the bead, reduces its height, and increases the wetting angle. It is established that the axial fusion depth depends on the surface area of the weldpool and does not vary monotonically with the spacing between electrodes. The results help optimize multi-wire welding parameters to improve productivity while maintaining quality.

Introduction. Increasing the productivity of single-wire surfacing through raising the wire feed rate causes defects — undercuts and poor fusion between layers, which reduces the quality of the deposited coating and increases the reject rate. To solve this problem, multiwire surfacing techniques are being developed in a shielded gas environment which increase productivity without compromising quality. The literature shows that the relative position of electrodes in multiwire systems affects significantly the thermal and electrophysical characteristics of the arc, and therefore, the geometry of the reinforcement and the shape of the fusion penetration. However, the available studies are fragmentary: there is insufficient data on the morphology of the fusion zone, and the relationship of its parameters and specific electrode arrangement schemes under twin-arc surfacing in a shielded environment, which leaves a scientific gap. The objective of this research is to evaluate the change in the geometric parameters of the reinforcement of the deposited layer and the morphology of the fusion zone with different relative positions of the electrodes under twin-arc surfacing in a shielded gas environment.

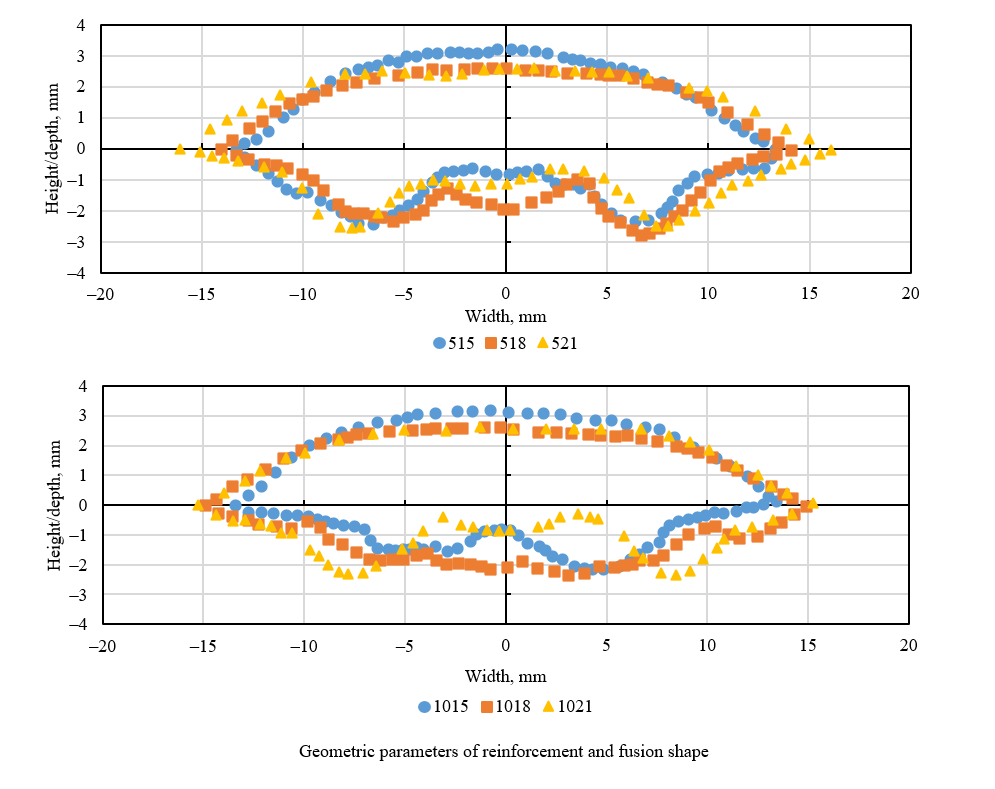

Materials and Methods. The experiment was conducted on a 6-axis Fanuc 120iD robot with an EWM Titan XQ500 power source and an experimental surfacing head consisting of two welding torches. The layers were deposited on steel substrates of grade St3 using the GMAW Pulse method with Sv 08G2S wire with a diameter of 1.2 mm in an Ar/CO₂ environment (98%/2%) under a fixed surfacing mode (WFS = 6.5 m/min for each torch, TS = 4 mm/s, MW = 150°C). The following parameters were adopted as the studied factors: distances between electrodes (z = 15, 18, 21 mm), their angle of inclination (α = 5°, 10°). On the cross-sections of the deposited layers prepared by grinding and etching, the geometric parameters of reinforcement (height h, width S, wetting angle γ) and fusion penetration (depths a, a₁, width b) were measured. Quantitative analysis of the weld geometry was performed using Digimizer software to assess the effect of the relative position of the electrodes on the formation of the layer.

Results. It has been found that the distance between the electrodes (z) affects significantly the reinforcement geometry: a growth of z causes an increase in the layer width (S) and the wetting angle (γ), but a decrease in its height (h). The axial fusion depth (a) demonstrated a nonlinear dependence on z, reaching a maximum (~2.2 mm) at z = 18 mm. The inclination angle (α) had a minor effect (<5%)on the reinforcement parameters, but affected significantly the shape of the main fusion zone (a₁): an increase in α decreased a₁ and made the penetration more gently sloping. At z = 21 mm, the impact of α on the penetration disappeared. The relationships between the relative positions of the electrodes under twin-arc surfacing, the geometric parameters of the reinforcement, and the depth of the fusion zone were specified.

Discussion. The explanation of the established dependences is based on the change in the thermal and electrophysical properties of the electric arc depending on the mutual arrangement of the electrodes. The axial depth of fusion penetration depends not only on the distance between the electrodes, but also on the volume of the weld pool. With an excessive volume of the weld pool for a specific surfacing mode, a damping effect of heat flows from the electric arc to the base metal occurs — the volume of the weld pool absorbs part of the heat, which causes a decrease in the depth of penetration. The change in the arc pressure vector with an increase in the angle between the electrodes explains the decrease in the depth of the main fusion zone.

Conclusion. The regularities of the effect of the mutual arrangement of electrodes on the geometry of the deposited layer and the shape of the fusion zone under twin-arc surfacing in a shielded gas have been experimentally established. It is shown that an increase in the distance between the electrodes results in an increase in the width of the bead, a decrease in its height, and an increase in the wetting angle. It has been noted that the penetration depth depends on the volume of the weld pool. It is determined that the angle of inclination of the electrodes in the studied modes has an insignificant effect — less than 5% — on the geometry of the deposited metal, although hypothetically, it can be enhanced at smaller interelectrode distances. The data obtained extract clear trends and form the basis for further in-depth study of the thermal and electrophysical aspects of the process of twin-arc surfacing in a shielded gas environment.

INFORMATION TECHNOLOGY, COMPUTER SCIENCE AND MANAGEMENT

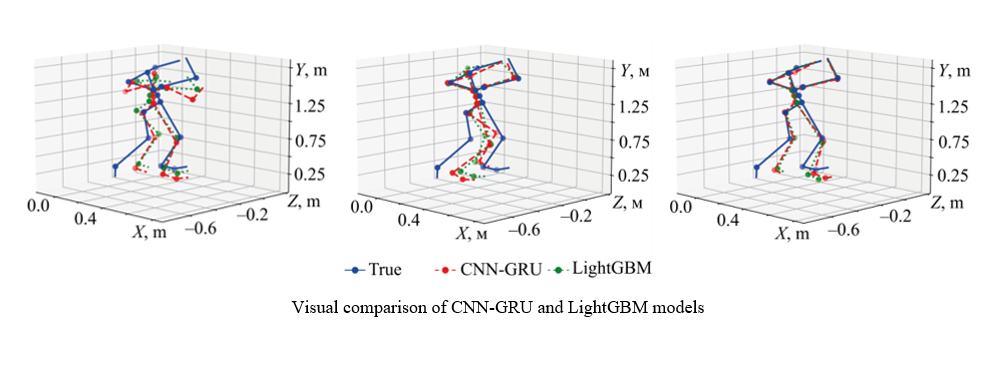

A method for reconstructing a full 3D skeletal pose from limited arm motion data is developed. It is shown that gradient tree ensembles yield the best average errors for most tasks. A CNN-GRU neural network with attention improves the overall error in a number of scenarios. First-person data without depth is shown to significantly reduce the accuracy of leg reconstruction. Inverse kinematics correction is shown to provide little improvement for individual poses. The results are applicable to virtual simulators and systems with a limited set of sensors.

Introduction. Accurate reconstruction of the human body model is required when visualizing digital avatars in virtual simulators and rehabilitation systems. However, the use of exoskeleton systems can cause overlapping and shielding of sensors, making it difficult for tracking systems to operate. This underlines the urgency of the task of reconstructing a human body model based on a limited set of data on arm movements, both in the field of rehabilitation and in sports training. Existing studies focus on either large-scale IMU networks or full video monitoring, without considering the issue of reconstructing a body model based on arm motion data. The objective of this research is to develop and test machine learning methods aimed at reconstructing body model coordinates using limited data, such as arm position information.

Materials and Methods. To conduct the study, a virtual simulation environment was created in which a virtual avatar performed various movements. These movements were recorded by cameras with a first-person and side view. The positions of the keypoints of the body model relative to the back point were saved as reference data. The regression task considered was to reconstruct the user's arm positions in a full body model in five different variations, including keypoint coordinates extracted from a video and a virtual scene. The task also involved comparing different regression models, including linear models, decision trees, ensembles, and three deep neural networks (DenseNN, CNN-GRU, Transformer). The accuracy was estimated using MAE and the mean Euclidean deviation of body segments. Experimental studies were conducted on five datasets, whose size varied from 25 to 180 thousand frames.

Results. The experiments showed that ensembles (LightGBM) were best-performing in most situations. Among neural network models, the CNN-GRU-based model provided the lowest error. Training models on a sequence of 20 frames did not give significant improvement. Using the inverse kinematics module on a number of scenarios allowed reducing the error to 3%, but in some cases worsened the final result.

Discussion. The analysis of the results obtained showed low reconstruction accuracy when using computer vision datasets, as well as the lack of superiority of complex models over simpler ensembles and linear models. However, the trained models allowed, with some error, for the reconstruction of the position of the user's legs for a more reliable display of the digital model of his body.

Conclusion. The data obtained showed the complexity of solving the problem of reconstructing a human body model using a limited amount of data, as well as a large error in a number of machine learning models. The comparison of models on different datasets proved low applicability of first-person data that did not contain information on the distance to the arms. On the other part, using absolute values of arm positions as input information provided for the reconstruction of the body model with significantly less error.

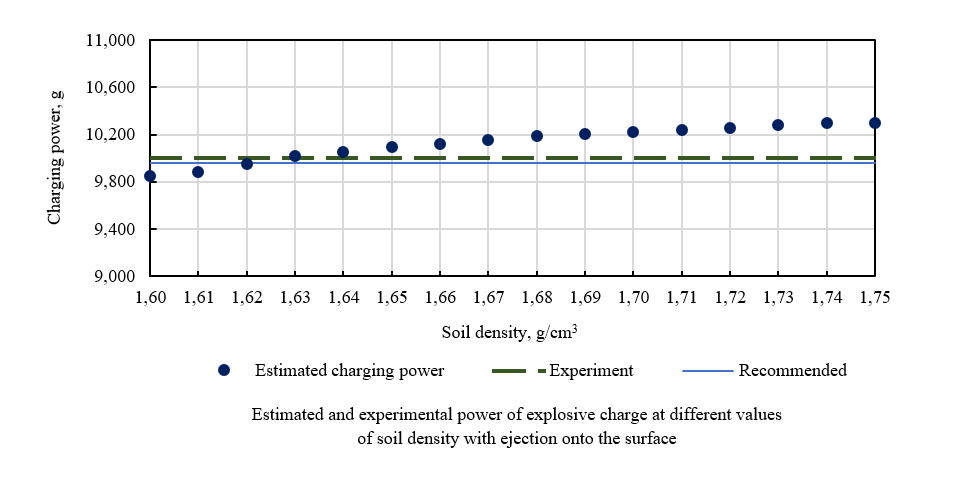

A mathematical model is developed for estimating the charge power during loess compaction using deep blasts. The model takes into account the mechanical-and-physical properties of soils and their isotropy or anisotropy. Analytical formulas are derived for cases with and without soil ejection. The conducted numerical experiment confirms the agreement between the calculations and field data. The model eliminates test blasts and reduces costs in compaction design. The method is applicable to design and survey organizations when planning engineering and technology processes.

Introduction. Subsidence loess soils, widespread in Russia, China and Central Asia, are a challenge in modern construction due to their tendency to subsidence and low strength under external loads. Insufficient attention to their mechanical-and-physical properties can cause deformation of structures, which creates a safety hazard and financial losses. Scientific research in this area is fragmentary and does not provide sufficient understanding of compaction methods and their impact on the durability of structures. Moreover, there are no developed optimized mathematical models to predict the efficiency of engineering and technology processes of compaction. Thus, the objective of this study is to develop a mathematical model that determines the explosive charge capacity for compaction of loess. This model is aimed at eliminating the experimental stage, which improves the quality of compaction and contributes to saving financial resources in construction.

Materials and Methods. Mathematical modeling was carried out by including the solution to the inverse applied problem of assessing the power of an explosive charge when eliminating loess subsidence. Initial-boundary value problems with a semiempirical partial differential equation describing the compaction of loess with and without the ejection of soil onto the construction site’s surface were considered by analyzing specific models and mathematical approaches. Based on the solution to these problems using the analytical method, a mathematical model for assessing the power of an explosive charge was developed. The power was determined numerically using two methods: calculations in a program developed in the Python language, and modeling a computational experiment with an assessment of the error of the result. In this case, the effect of the mechanical-and-physical properties of soils, their isotropy and anisotropy were taken into account.

Results. A mathematical model of the explosive charge power during compaction of subsiding loess using deep hydraulic blasts was constructed. The density of dry soil before and after compaction, the vertical diffusion coefficient, dispersion coordinate changes of gas in the compacted soil, and the depth of the explosive charge were taken into account. With an average density of dry compacted soil, the absolute error of the calculated values of the charge power was 3.28 g for compaction of loess without ejection, and 21.13 g for the situation with soil ejection onto the surface. The adequacy of the proposed mathematical solution to the experimental data of a full-scale construction site was shown.

Discussion. The proposed model allows for the assessment of the explosive charge power for isotropic and anisotropic geological systems. The resulting analytical representations demonstrate the degree and nature of the influence of mechanical-and-physical properties of soils on the magnitude of the charge power. Numerical comparison with both experimental data on natural soil compaction and recommendations for compaction of subsidence soils of high power by the hydraulic blasting method has shown that the proposed mathematical model is consistent with empirical data.

Conclusion. The main result of the study is a mathematical model of the explosive charge power when eliminating loess subsidence using deep hydraulic blasts. Analytical representations of the charge power are constructed taking into account the mechanical-and-physical properties of soils. A numerical estimate of the power consistent with the values of empirical data is obtained. The practical significance of the study involves the possibility of using the mathematical model as a calculation method and implementing it in research and design organizations. Further study will be aimed at constructing solutions using mathematical modeling and other inverse problems within the framework of the engineering and technology process of soil compaction.

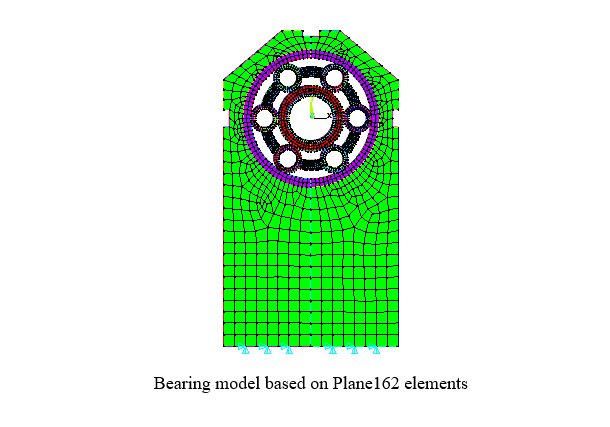

A combined method for generating bearing vibration signals is developed on the basis of the experience and finite element modeling. This model-based approach provides the generation of pulse sequences corresponding to different stages of a local defect. The resulting combined signals accurately reproduce the growth of statistical diagnostic parameters. This method compensates for the lack of experimental data at the early stages of a defect without damaging equipment. The resulting signal set is suitable for testing and validating vibration diagnostic algorithms.

Introduction. The creation of reliable test sets of vibration signals remains a critical challenge in vibrodiagnostics, as the lack of data on early-stage bearing defects hinders the development and validation of diagnostic algorithms. Experimental acquisition of such signals is limited by the absence of appropriate test specimens and the long duration required for defect progression. Existing numerical simulation approaches demand high computational resources and complex setup, reducing their practical applicability. A significant gap in current research is the absence of a simple, reproducible, and validated methodology for generating signals that reflect the progressive development of defects. The objective of this study is to create a simplified methodology for generating a test set of bearing vibration signals that can be used to develop and verify new vibrodiagnostic techniques. The methodology is based on a combination of experimental and simulated signals.

Materials and Methods. Experimental data were obtained from a laboratory setup simulating a rotor unit with a rolling bearing (type 180603). To simulate early-stage defects (single and double chipping pits), dynamic finite element modelling was performed using ANSYS Mechanical (version 16.2) based on plane elements Plane162 using the LS-DYNA package. The resulting impulse sequences were superimposed onto the measured signal from a healthy bearing to generate combined signals. All signals (3 experimental, 2 combined) were analyzed using Fourier transform, bandpass filtering (5.4 kHz), and calculation of statistical parameters: root mean square (RMS), crest factor, and excess coefficient. Analysis was conducted in Mathcad (version 15.0).

Results. As a result of the study, a method for generating a test set of vibration signals from a rolling bearing was developed, covering the serviceable state and the sequential development of a local defect of the outer ring. The results showed a correlation between the amplitude of vibration signals and the stages of defects — an increase in amplitudes was observed in the high-frequency region, which confirmed the interaction of rolling elements and defective surfaces. Additional statistical analysis revealed an increase in diagnostic parameters (RMS value, crest factor, and excess coefficient) as the damage developed. It was found that the simulated signals reproduced the characteristic signs of a defect and fitted correctly into the general trend of parameter changes.

Discussion. The data obtained demonstrate that the proposed technique makes it possible to simplify the generation of reference signals without the need for long-term accumulation of experimental data or damage to equipment. The physical validity of the simulated pulses and the consistency of growth dynamics of diagnostic parameters with real data confirm the possibility of using this method for standardized testing of vibrodiagnostic techniques.

Conclusion. The developed methodology provides an efficient and reproducible approach to generating test signal sets for vibrodiagnostics. It can be used to accelerate algorithm verification, reduce experimental costs, and improve diagnostic reliability. Future research will focus on simplifying impulse generation through analytical modelling and extending the methodology to other bearing types and defect forms.

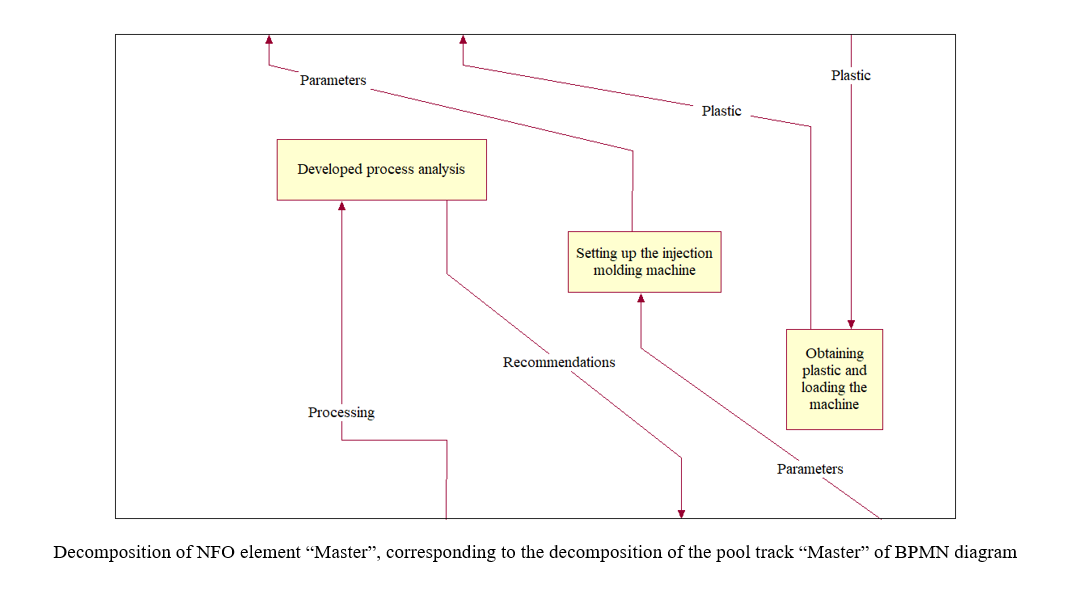

A universal method for converting diagrams between NFO and BPMN notations to improve clarity is presented. Six operations for converting NFO to BPMN and four operations for the reverse transformation are developed. It is shown that NFO notation reduces the number of graphic icons and simplifies diagram reading.

NFO elements are described in XPDL, a process execution language, for subsequent automation. The method provides the consideration of material and information flows and the functional-cost analysis. The results are applicable to the design, automation, and optimization of production processes.

Introduction. The BPMN standard system (notation) is widely used in business process modeling. However, it is not expressive enough to represent technical and production mechanisms. BPMN poorly describes parallel flows with strict resource constraints, insufficiently supports modeling of physical parameters and technological conditions. These and other shortcomings worsen the analysis of performance and reliability, reduce the applicability of models for optimization and verification. The objective of the presented work is to create a method that uses an alternative notation and thus limits the impact of the listed shortcomings of BPMN in modeling production processes.

Materials and Methods. The basis of the new solution was a comparison of BPMN and the notation for the system “node – function – object” (NFO). The elements of the diagrams were the intersections of some connections (nodes). They contained functional elements (functions, processes), which in some cases also had the characteristics of a substance (objects). A comparative analysis of the normative systems of BPMN and NFO showed the possibility of mutual transformation of diagrams. The processes were visualized using the CASE (Computer Aided Software Engineering) tool NFO-toolkit and the Stormbpmn program according to the BPMN rules. The NFO diagram was described in the XPDL2 language.

Results. Six sequential operations have been developed for converting a NFO diagram into BPMN, and four — for the reverse transformation. The scheme of component production is shown in the context and decomposition, from the requirement for the development of the workflow to the issuance of products. Decompositions of the NFO elements “Injection Molding Machine”, “Master” and “Development Department” are presented, each of which corresponds to a decomposition of the same-name track of the BPMN notation pool. It has been proven that converting a BPMN diagram to a NFO improves the description of the process as a whole and to any degree of detail. The NFO approach does not refer to the graphical notation system of BPMN, which increases labor costs and the risk of simulation errors. The XPDL language describes processes, connectors, splitters, relationships, external entities, and other elements of NFO diagrams.

Discussion. The main advantages of NFO notation over the BPMN approach are: easier procedure for creating models and their better visualization. A simple graphic set of NFO reduces simulation time and increases its accuracy. The NFO approach is focused on taking into account information and material connections. This means that it is possible to conduct functional cost CASE analysis, which is impossible using the BPMN method. The XPDL language is suitable for describing elements of NFO diagrams, and the solution can be Russified.

Conclusion. Content redundancy and other shortcomings of the BPMN notation are eliminated through using a more universal and convenient notation — NFO. The research results will contribute to the development of the theory and practice of graphanalytic modeling of production processes, and simplify the procedure for their development and automation.